Monitoring method for monitoring accuracy of environment detection equipment

A technology for environmental detection and detection equipment, applied in the field of monitoring, can solve the problems of inconvenient construction on site, damage to the electrical/technical structure of environmental detection equipment, etc., and achieve the effects of simple structure, guaranteed accuracy, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

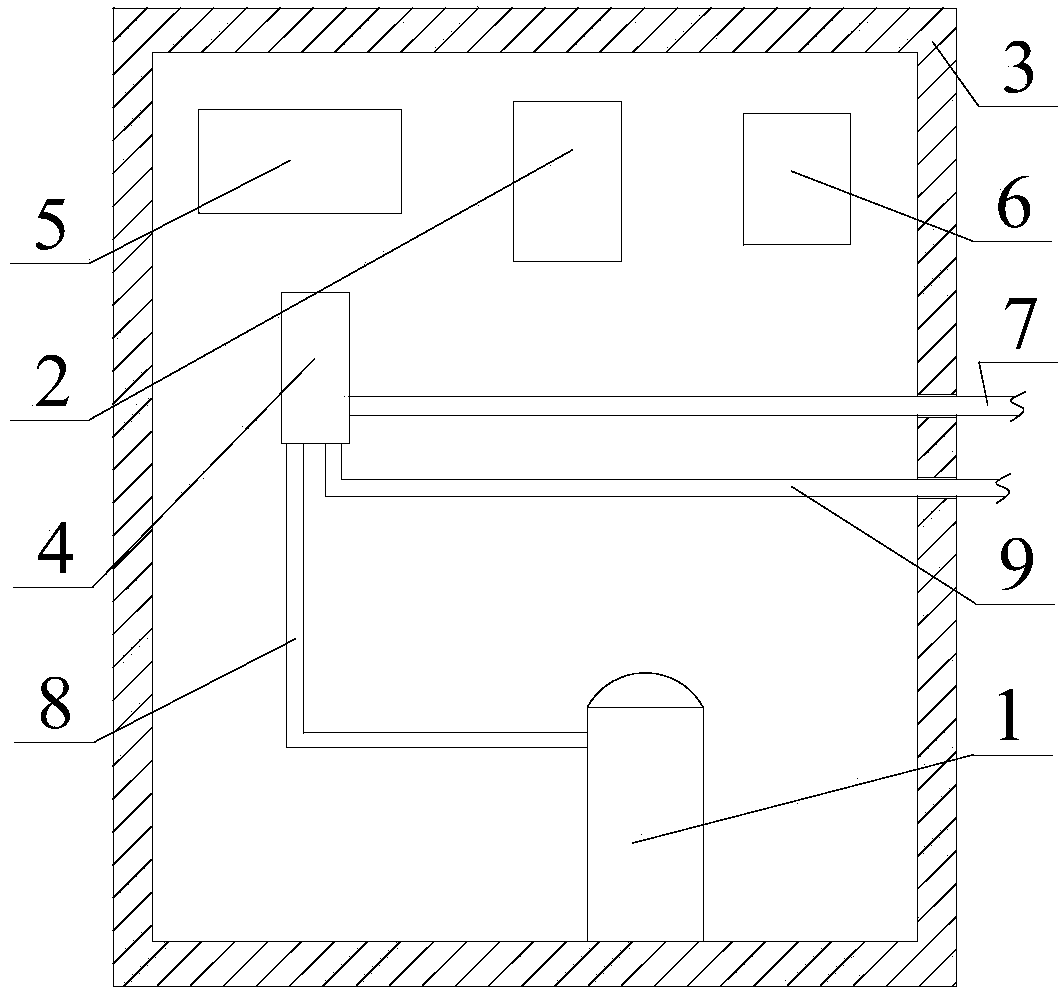

[0016] Embodiment 1. When the environmental detection equipment detects gas, standard substance storage tank 1 is filled with standard gas, and the gas pressure is 10-12MPa. The standard substance storage tank 1 is provided with a flow sensor and a pressure sensor, a flow sensor and a pressure sensor. The sensors are all connected to the wireless transceiver device 6. When the gas flow rate in the standard substance storage tank 1 is less than 1.5L / min or the gas pressure exceeds 10-12MPa, the flow sensor or pressure sensor outputs a signal to the background management center through the wireless transceiver device 6. Processing device, the processing device in the background management center sends an alarm signal to remind the staff to replace the standard substance storage tank 1 or to adjust the air pressure valve on the standard substance storage tank 1 on site.

[0017] When it is necessary to monitor the test results of the environmental testing equipment, the control de...

Embodiment 2

[0018] Embodiment 2. When the environmental detection equipment detects liquids, the standard substance storage tank 1 is filled with a standard liquid with a temperature of 2 to 8°C. The standard substance storage tank 1 is provided with a liquid level sensor and a temperature sensor. 3, an insulated box is added, the standard substance storage tank 1 is arranged in the insulated box, and a silicon semiconductor refrigerator is arranged in the insulated box, and the use of the insulated box is more conducive to making the liquid temperature in the standard liquid storage tank 3 Keep it at 2-8°C. Both the liquid level sensor and the temperature sensor are connected to the wireless transceiver device 6, and the silicon semiconductor refrigerator is connected to the control device 2. When the liquid level in the standard substance storage tank 1 is lower than 100ml, the liquid level sensor passes through The wireless transceiver device 6 outputs a signal to the processing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com