Czochralski centering calibration system and calibration method for single crystal furnace

A technology of calibration system and calibration method, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of poor reproducibility, low detection efficiency, and large error range, and achieve good consistency and high detection efficiency. Improve the effect of small error range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

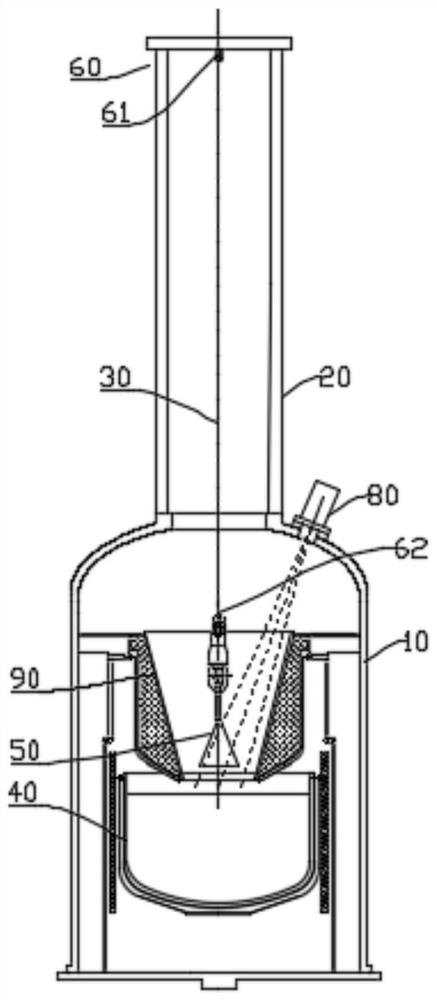

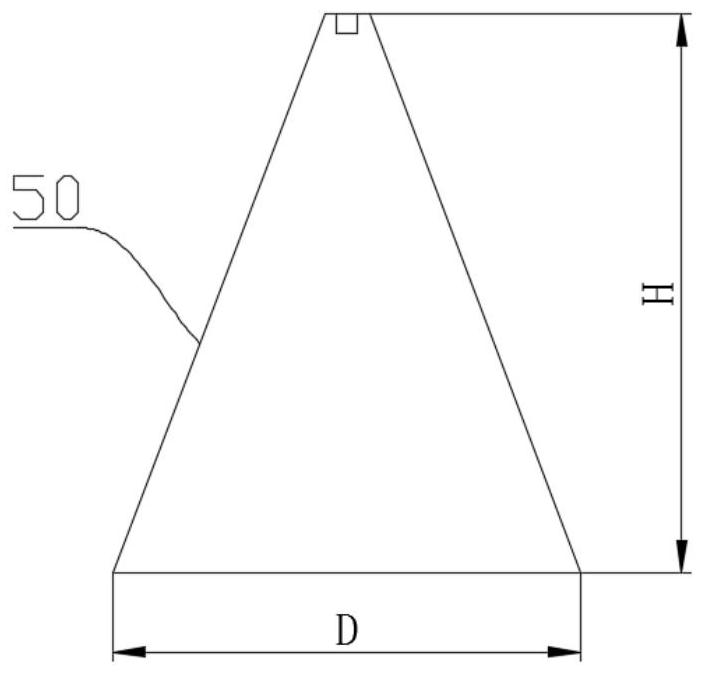

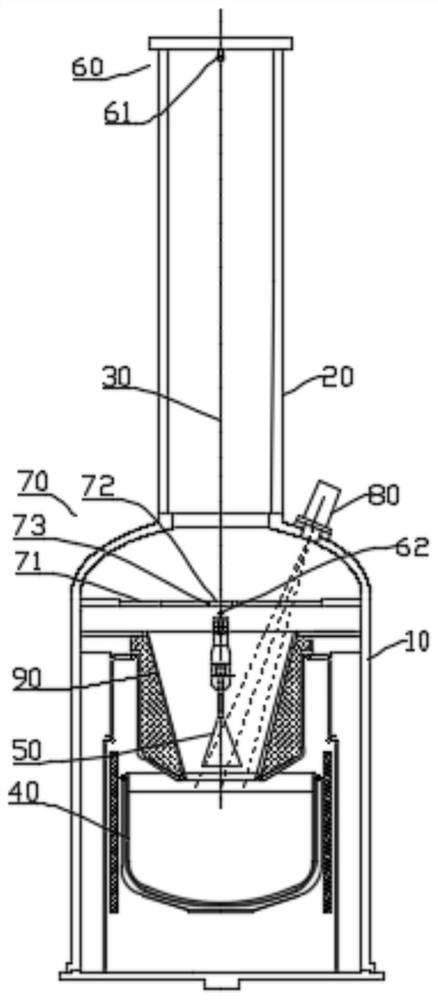

[0038] This embodiment proposes a single crystal furnace Czochralski alignment calibration system, such as figure 1 As shown, it is used to calibrate the coaxial line between the pulling steel wire 30 and the quartz crucible 40, including: a calibration part 50 placed inside the main chamber 10 of the single crystal furnace and suspended in the air, a monitoring part 60, and a monitoring part 60 for A connected processor, wherein the monitoring part 50 is coaxially arranged with the lifting steel wire 30, and is used to monitor whether the pulling steel wire 30 is coaxial with the calibration part 50; the lifting steel wire 30 is straightened and set; The weight at the lower end of the steel wire 30 is connected, and the height of the lower end surface of the calibration part 50 from the upper end surface of the quartz crucible 40 is 50-60 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com