A snap-on relay

A relay, one-to-one correspondence technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of high maintenance and replacement costs, high glue costs, and bottom plate falling off, so as to simplify fastening installation and ensure installation Strength and aesthetic improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

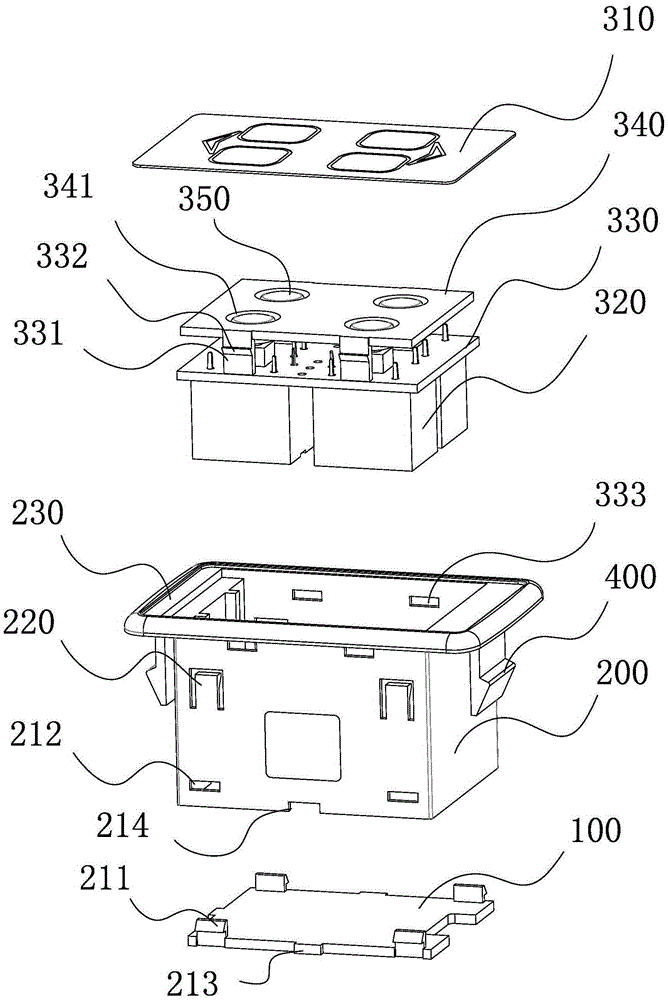

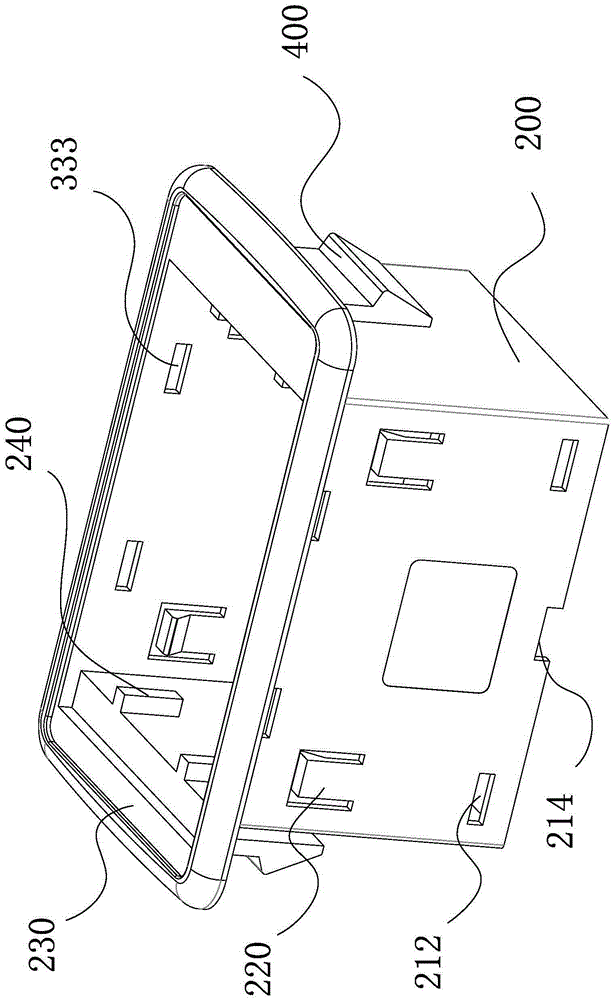

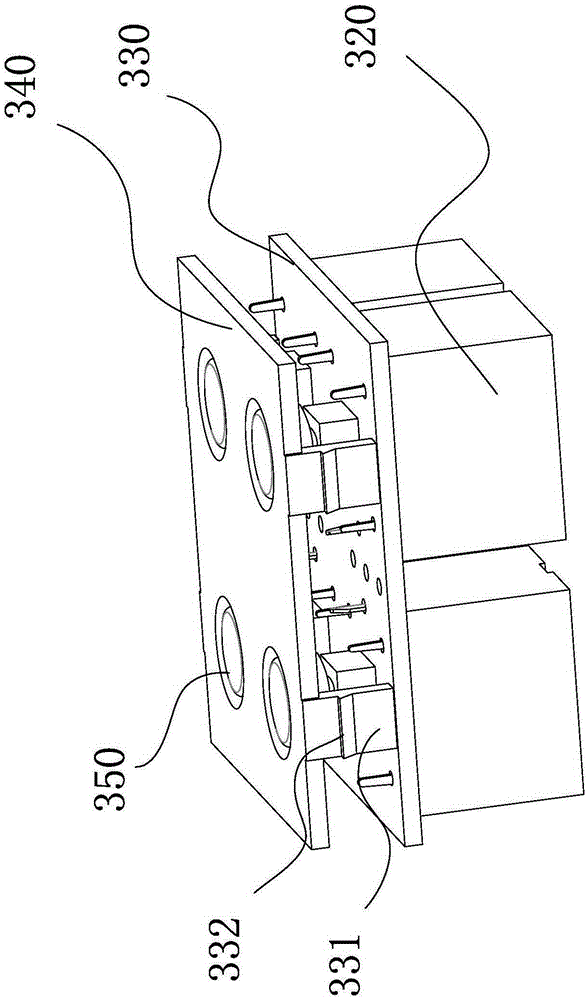

[0026] Such as Figure 1 to Figure 4 As shown, the clip-on relay includes a bottom plate 100, an outer casing 200 and a control assembly. The control assembly includes a control panel 310 clamped on the top of the outer casing 200 and a plurality of control coils 320 installed in the outer casing 200. The bottom plate 100 passes through The buckle structure is fastened on the bottom of the outer casing 200, the buckle structure includes a locking piece and a positioning piece, the locking piece includes a number of hooks 211 fixedly connected to the bottom plate 100 and a number of slots 212 corresponding to the hooks 211 one by one , the hook 211 is set in the slot 212; the positioning member includes a plurality of posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com