Method for manufacturing three-dimensional integrated inductor structure

An integrated inductance, three-dimensional technology, applied in the direction of inductors, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing the inductance value, unable to increase the inductance magnetic flux, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

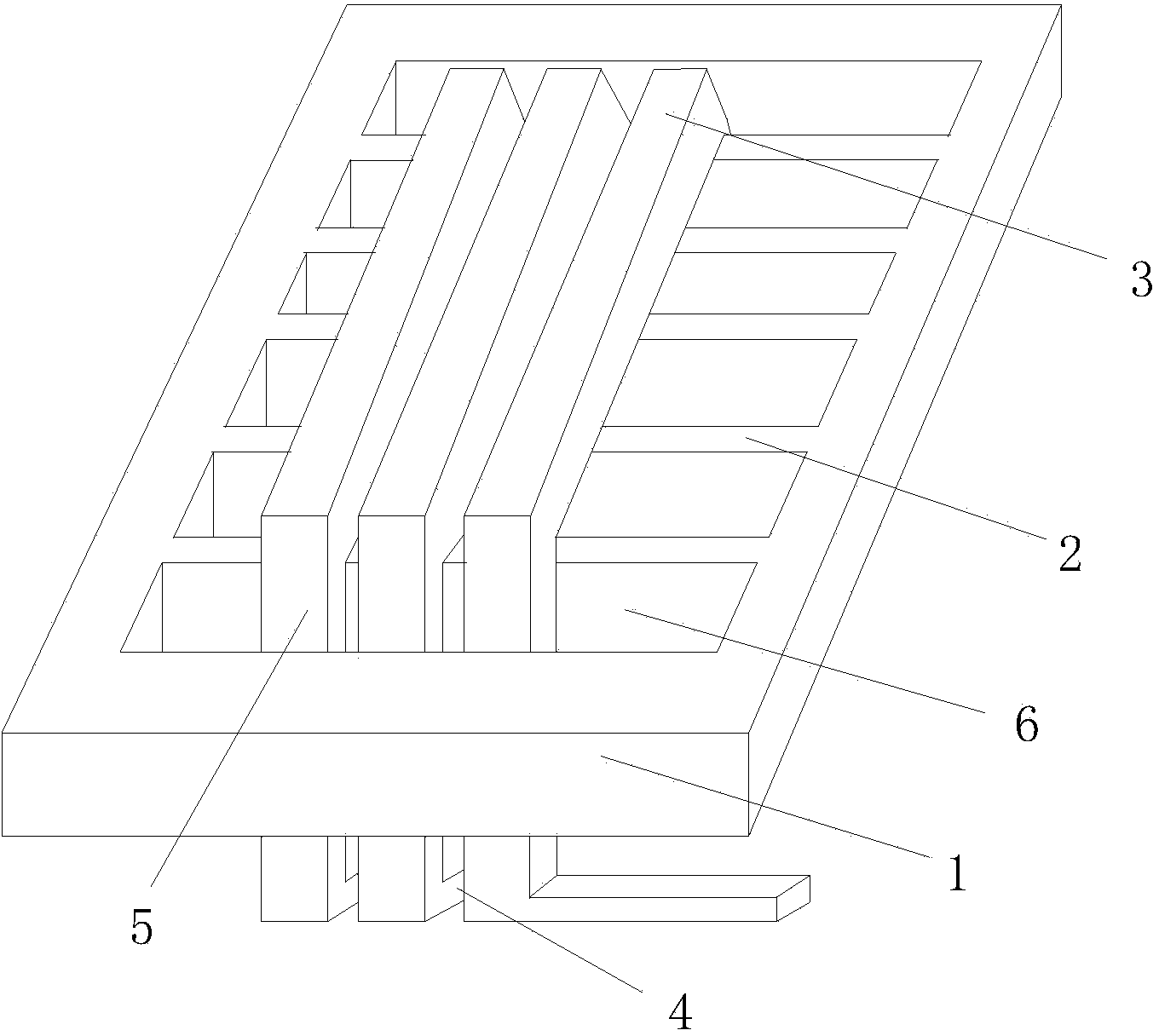

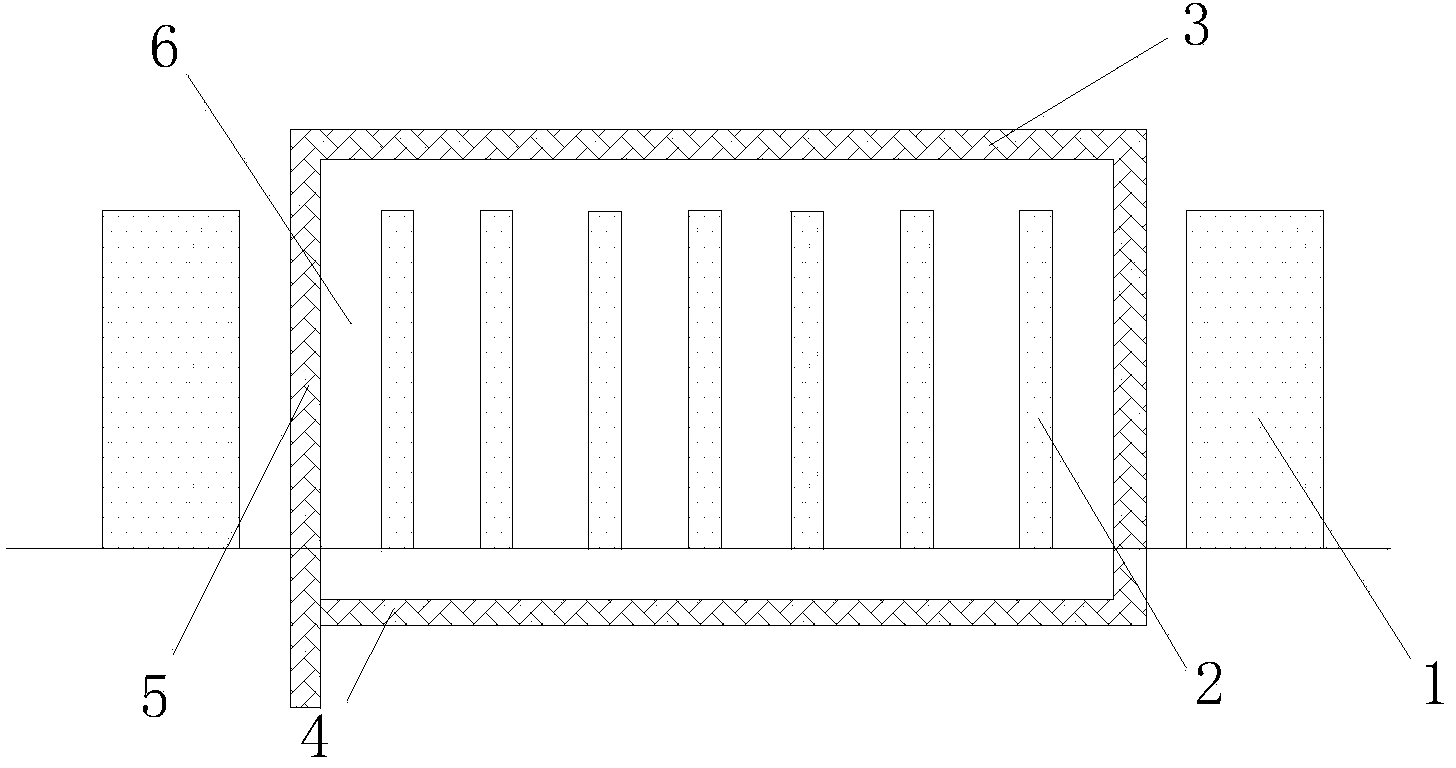

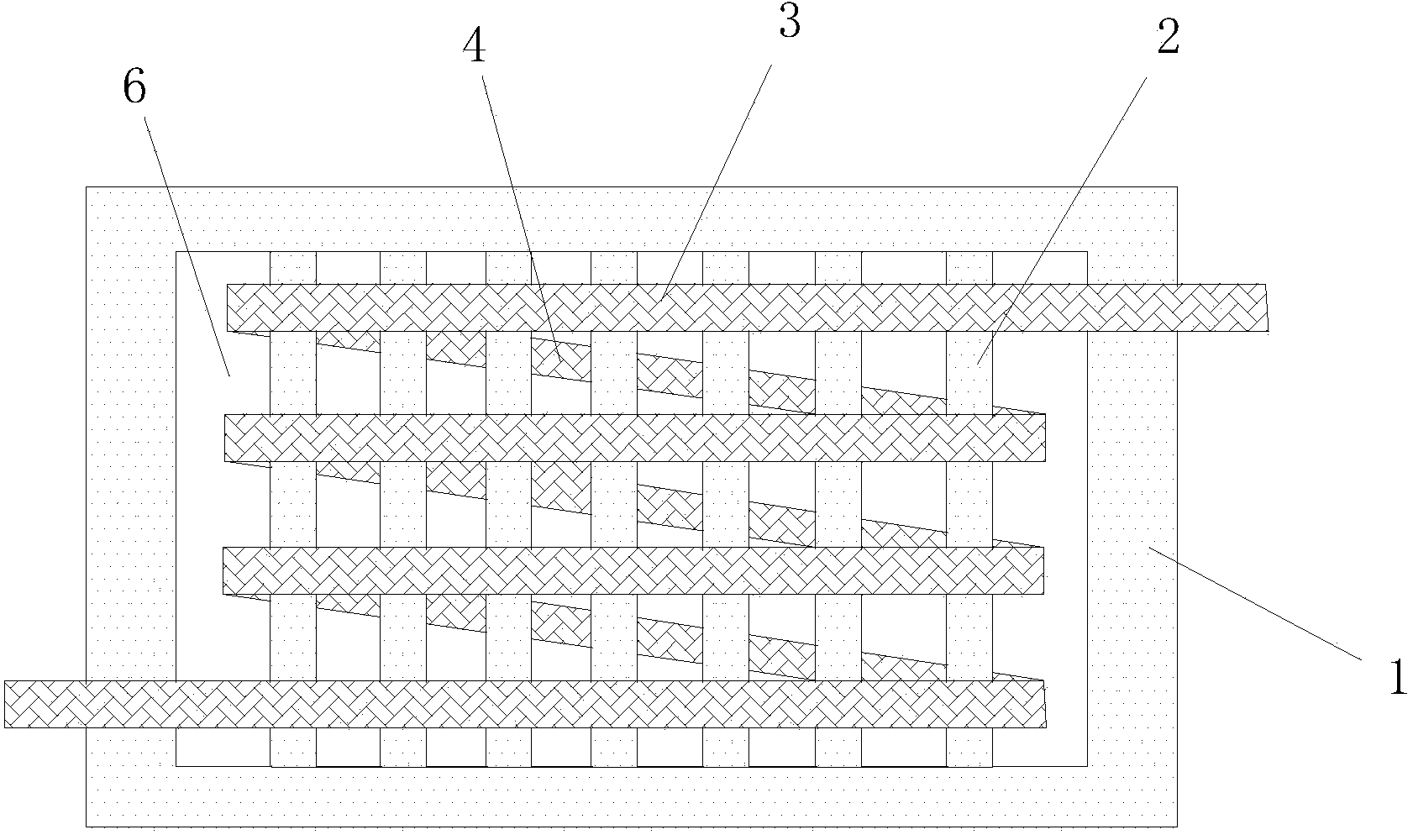

[0034] In order to increase the magnetic flux of the inductor to increase the inductance value while reducing the eddy current, and improve the quality factor Q value and the performance of the inductor coil, it is necessary to prepare a three-dimensional integrated inductor structure, including: a metal frame, in the area surrounded by the metal frame There are a number of side-by-side chip cores, and the two ends of each core are fixed on the opposite sides of the metal frame; in addition, it also includes an inductance coil, which is in a three-dimensional spiral shape and surrounds the metal frame in multiple turns in one direction. on all cores in the area.

[0035] The present invention will be described in detail below in conjunction with specific drawings.

[0036] Such as Figure 1~8b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com