Anti-glare and weather-resistant composite material

A composite material and anti-glare technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as heat dissipation difficulties, damage to cells, and reduced power generation efficiency, so as to reduce reflectivity, improve photoelectric conversion efficiency, and reduce reflection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

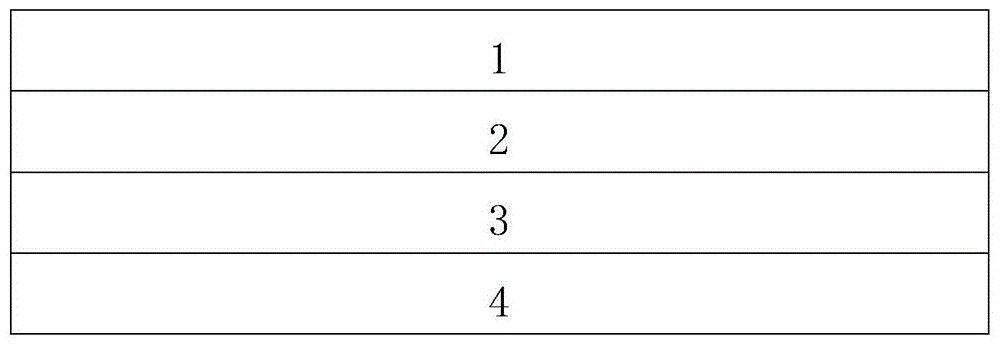

[0024] Such as figure 1 as shown,

[0025] An anti-glare and weather-resistant composite material, which includes a surface protection layer 1, a light anti-reflection layer 2, a high light-transmitting plastic base layer 3 doped with quantum dots, and a high light-transmitting packaging material layer 4, which are sequentially stacked from top to bottom;

[0026] Wherein, the light antireflection layer 2 includes N layers of plastic blended layers of fluoroplastics and acrylic plastics, 1≤N≤9; the weight ratio of fluoroplastics in the N layers of plastic blended layers decreases successively, and The rate increases step by step;

[0027] The quantum dots are nanoparticles made of semiconductor materials with a diameter of 2-20nm, and the doping amount is 0.1%-2% by weight.

[0028] Quantum dots are generally spherical or quasi-spherical, and are nanoparticles made of semiconductor materials (usually composed of II B-VIB or IIIB-VB elements) with a stable diameter of 2-20 nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com