Lc snubber circuit

A snubber circuit and snubber diode technology, applied in electrical components, high-efficiency power electronics conversion, output power conversion devices, etc., can solve problems such as narrow power supply voltage range, achieve low switching voltage stress, reduce peak voltage stress, reduce Effect of Small Conduction Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

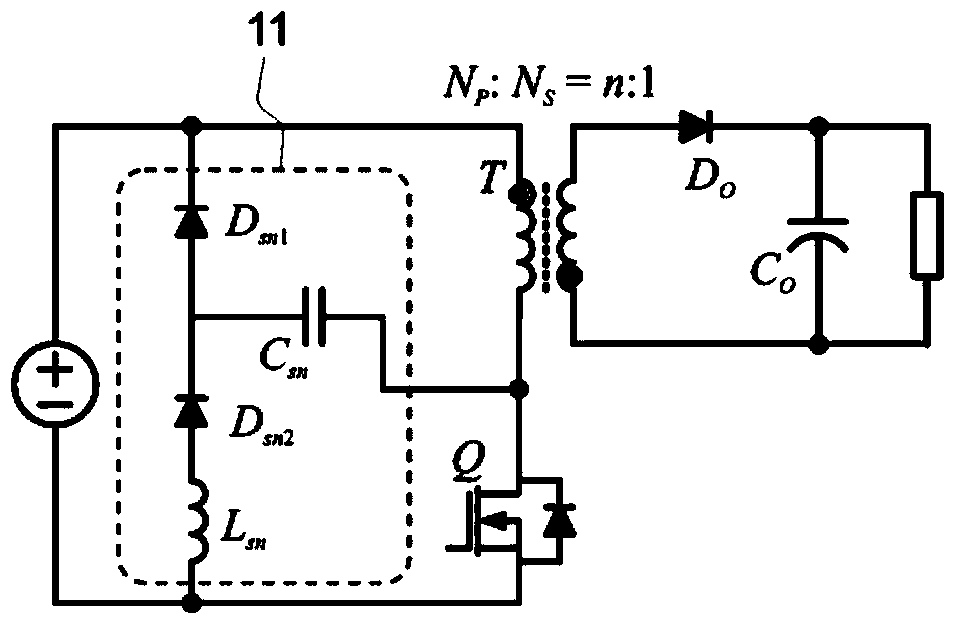

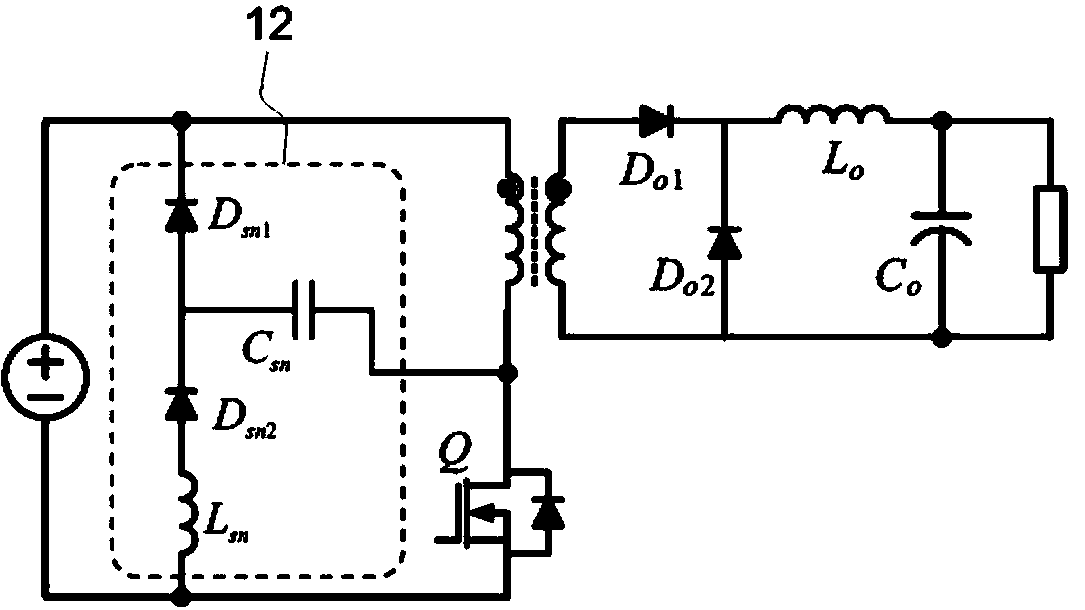

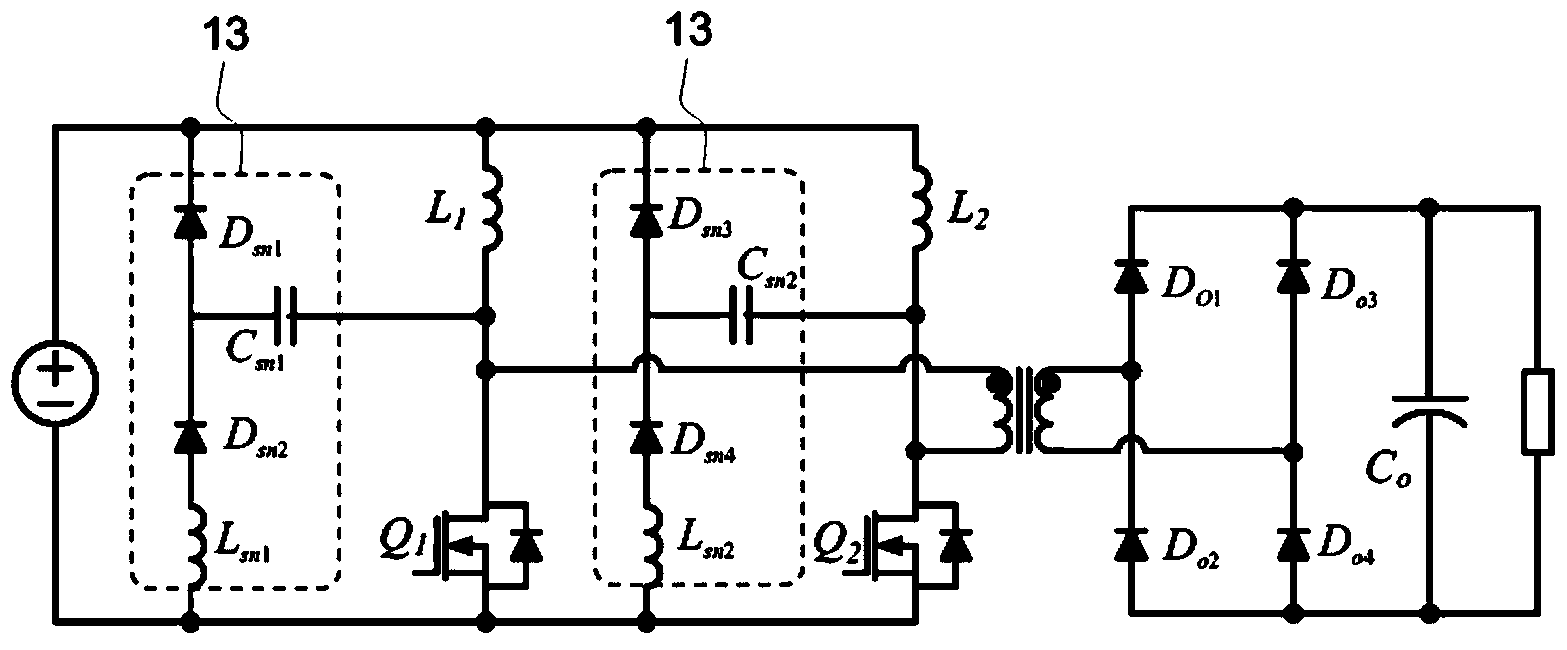

[0021] Next, install the flyback converter such as Figure 1a The principle of operation of the illustrated conventional LC buffer is discussed in more detail. Circulating currents causing additional conduction losses were also investigated. Figure 2a to Figure 2c show Figure 1a Exemplary voltage waveforms and exemplary current waveforms for the buffer shown in . exist Figure 2a The magnetizing current I of the transformer T is shown in Lm and leakage current I lkg , and the current I through the switching device Q Q ;exist Figure 2b The voltage V across the switching device Q is shown in Q and in the snubber capacitor C sn The voltage on V Csn ;exist Figure 2c is shown through the snubber diode D sn1 current I Dsn1 and through the snubber diode D sn2 current I Dsn2 .

[0022] Figure 3a to Figure 3e show Figure 1a current path of the LC snubber. For circuit analysis, use Figure 3a to Figure 3e Including ideal transformer, magnetizing inductance L m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com