Intelligent Power Control Circuit

A control circuit and intelligent power technology, applied in the field of electronics, can solve the problems of increasing the on-duty ratio of the power tube, increasing the average current of the LED, serious heating of the power tube, etc., to reduce power consumption, limit the temperature rise, and have a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

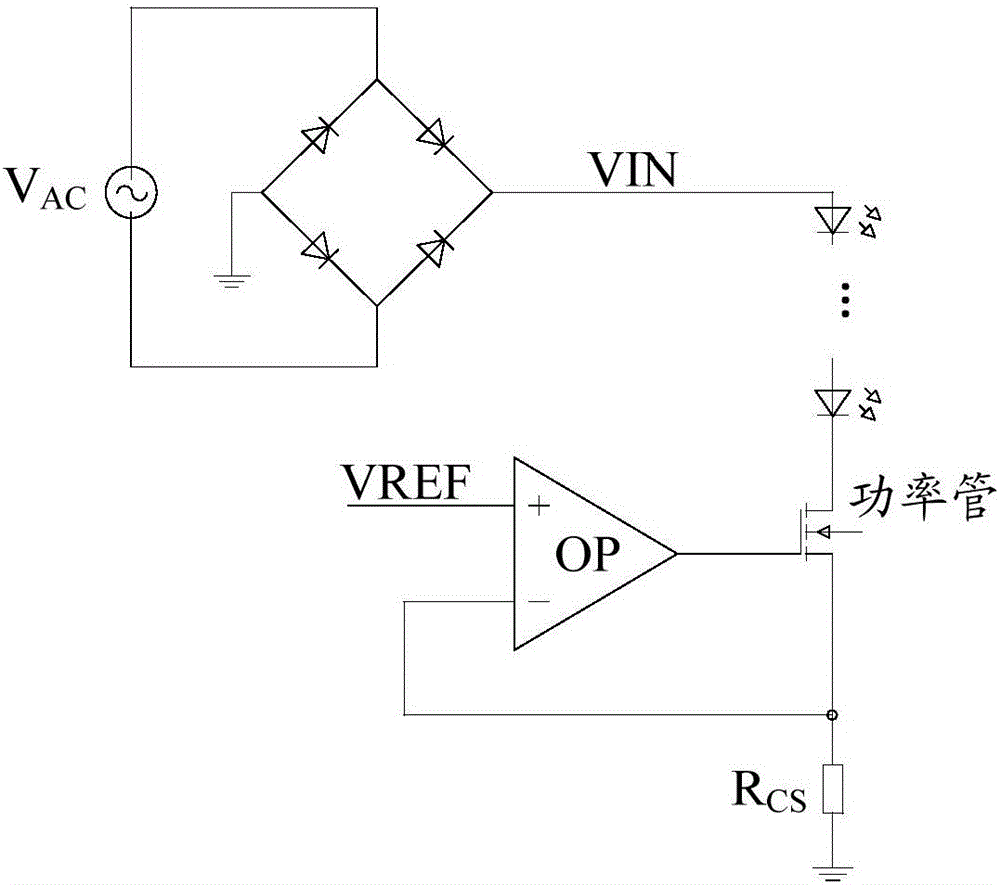

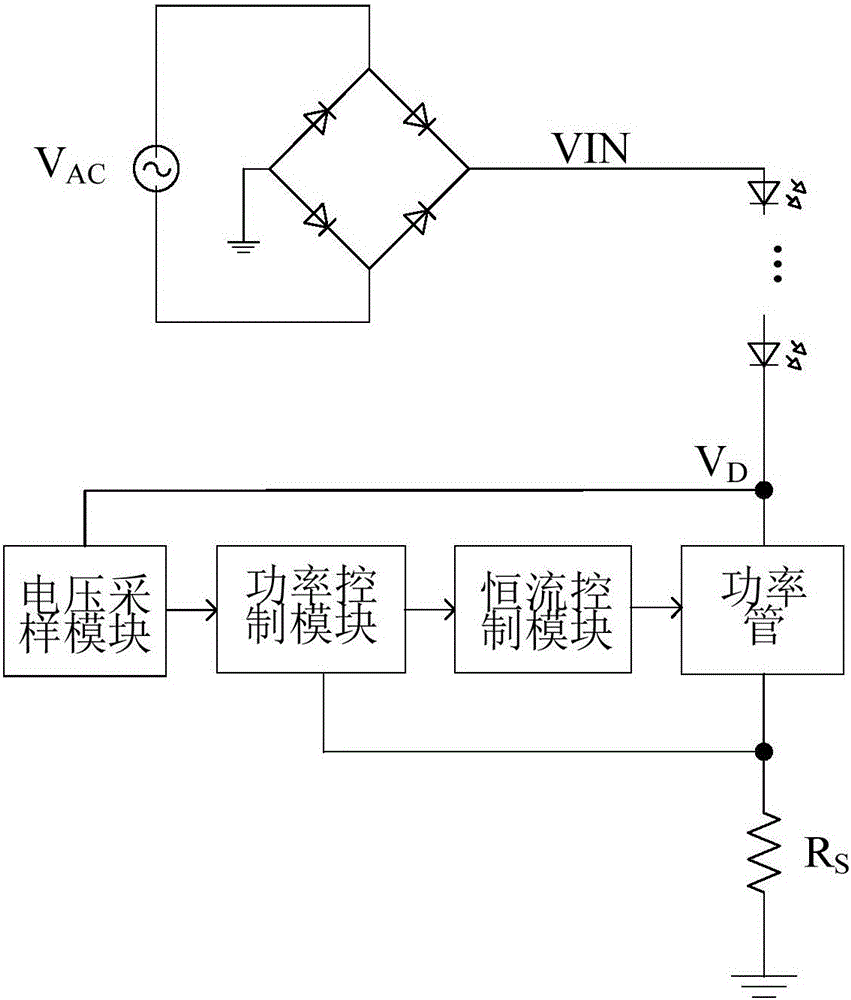

[0034] see Figure 3 to Figure 4 As shown, the intelligent power control circuit of the present invention includes a voltage sampling module, a power control module and a constant current control module; the input end of the voltage sampling module is connected to the first end of the power tube, and the voltage sampling module The output end is connected to the input end of the power control module, the output end of the power control module is connected to the input end of the constant current control module, and the output end of the constant current control module is connected to the The third end of the power tube mentioned above is connected.

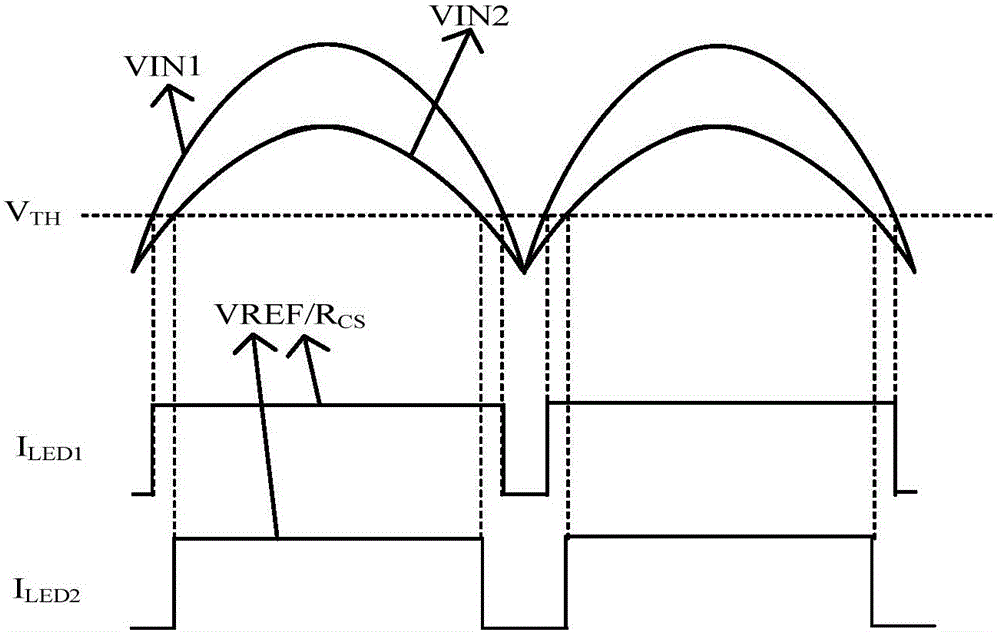

[0035] where the input voltage V AC After distillation and filtering to obtain a half-wave, VIN is obtained. The voltage VIN is input to the LED lamp, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com