Method for solidifying copper foil and base material of roll-type IC card circuit board

A curing method and circuit board technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of substrate wrinkles, layered deformation, and inability to achieve peel strength, etc., and achieve the effect of solving cumbersome processes and solving wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A method for curing the copper foil and base material of a roll-type IC card circuit board, comprising the following two steps:

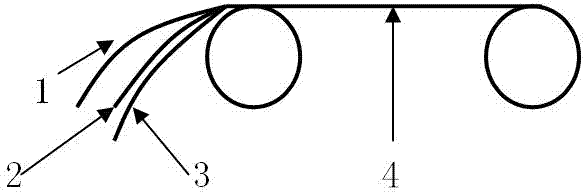

[0014] 1) if figure 1 As shown, the roll-type substrate 1, bonding glue 2, and copper foil 3 are first bonded together by a roll-to-roll laminating device, so that it becomes a roll with copper foil 3 and glue 2 pre-fixed on the Uncured bulk substrate 4 on substrate 1;

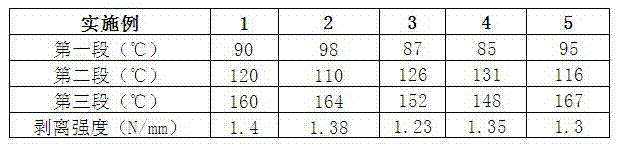

[0015] 2) Curing the bonded whole roll of substrate 4 in three stages, the first stage is heated at 90°C for one hour to make the inside of the adhesive 2 flow evenly; then heated at 120°C for two hours to cure the substrate 4 at high temperature; finally Then heat at 160° C. for three hours to fully mature the bonding glue 2 and let it cool down naturally.

[0016] working principle:

[0017] Firstly, the rolled base material 1, bonding glue 2, and copper foil 3 are pasted together by a bonding device, and then the bonded whole roll of substrate is cured by a three-stage...

Embodiment 2

[0019] A method for curing the copper foil and base material of a roll-type IC card circuit board, comprising the following two steps:

[0020] 1) if figure 1 As shown, the roll-type substrate 1, bonding glue 2, and copper foil 3 are first bonded together by a roll-to-roll laminating device, so that it becomes a roll with copper foil 3 and glue 2 pre-fixed on the Uncured bulk substrate 4 on substrate 1;

[0021] 2) Curing the bonded whole roll of substrate 4 in three stages, the first stage is heated at 98°C for one hour to make the inside of the adhesive 2 flow evenly; then heated at 110°C for two hours to cure the substrate 4 at high temperature; finally Then heat at 164° C. for three hours to fully mature the bonding glue 2 and let it cool down naturally.

Embodiment 3

[0023] A method for curing the copper foil and base material of a roll-type IC card circuit board, comprising the following two steps:

[0024] 1) if figure 1 As shown, the roll-type substrate 1, bonding glue 2, and copper foil 3 are first bonded together by a roll-to-roll laminating device, so that it becomes a roll with copper foil 3 and glue 2 pre-fixed on the Uncured bulk substrate 4 on substrate 1;

[0025] 2) Curing the bonded whole roll of substrate 4 in three stages, the first stage is heated at 87°C for one hour to make the inside of the adhesive 2 flow evenly; then heated at 126°C for two hours to cure the substrate 4 at high temperature; finally Then heat at 152° C. for three hours to fully mature the bonding glue 2 and let it cool down naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com