Wax based oily turbid liquid used for stone materials and preparation method thereof

A suspension, wax-based technology, applied in chemical instruments and methods, polishing compositions, etc., can solve the problems of marble rust and water spots, cumbersome waxing process, low material utilization rate, etc., to achieve long retention time, polishing High efficiency and the effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Wax-based oily suspension 1 for stone materials consists of the following components:

[0072] Candelilla Wax

22.5

2.5

25

ethylene glycol

50

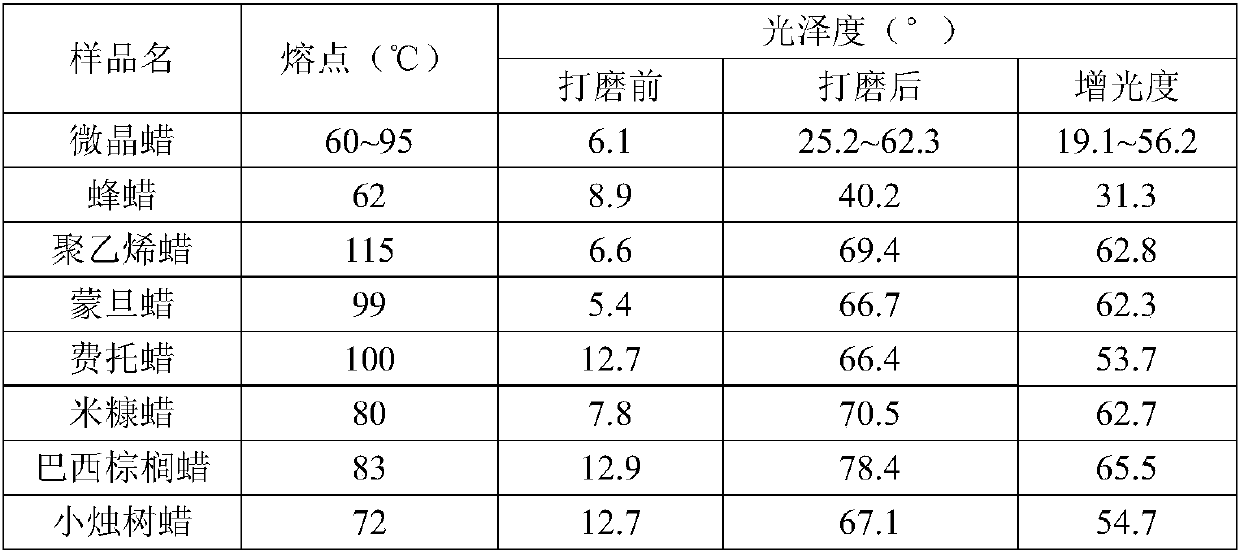

[0073] 1) Weigh 22.5 parts of candelilla wax and 2.5 parts of beeswax, put them in 25 parts of petroleum hydrocarbon, raise the temperature to 120° C., and stir for 30 minutes to obtain a brightener solution.

[0074] 2) Take 50 parts of ethylene glycol, set the speed of the high-speed disperser to 3000 rpm, stir for 10 minutes, slowly add the brightener solution in step 1), and continue high-speed dispersion for 90 minutes.

[0075] 3) The liquid in step 2) was placed in a high-pressure homogenizer with a pressure of 2000 bar and circulated for 3 times to obtain a wax-based oily suspension 1 for stone materials.

Embodiment 2

[0077] Wax-based oily suspension 2 for stone materials consists of the following components:

[0078]

[0079] 1) Weigh 4 parts of montan wax, 1 part of beeswax, 1 part of 1500 mesh quasi-spherical silica, 0.5 part of alkylphenol polyoxyethylene ether, place in 5 parts of trichlorethylene, and raise the temperature to 80°C, stirred for 15 minutes to obtain a brightener solution.

[0080] 2) Weigh 0.5 parts of organobentonite and place it in 88 parts of isopropanol, set the speed of the high-speed disperser to 1000 rpm, stir for 5 minutes, slowly add the brightener solution in step 1), and continue high-speed dispersion for 30 minutes.

[0081] 3) The liquid in step 2) is placed in a high-pressure homogenizer with a pressure of 1000 bar and circulated once to obtain a wax-based oily suspension 2 for stone materials.

Embodiment 3

[0083] Wax-based oily suspension 3 for stone materials consists of the following components:

[0084] Fischer-Tropsch wax

8.5

beeswax

1.5

tetrachlorethylene

10

76

2000 mesh zirconia

2

Fatty alcohol polyoxyethylene ether

1

polyamide wax

1

[0085] 1) Weigh 8.5 parts of Fischer-Tropsch wax, 1.5 parts of beeswax, 2 parts of 2000 mesh zirconium dioxide, and 1 part of fatty alcohol polyoxyethylene ether, place them in 10 parts of tetrachlorethylene, raise the temperature to 90 ° C, and stir After 20 minutes, a brightener solution was obtained.

[0086] 2) Weigh 1 part of polyamide wax and place it in 76 parts of n-butanol, set the speed of the high-speed disperser to 1000 rpm, stir for 5 minutes, slowly add the brightener solution in step 1), and continue high-speed dispersion for 60 minutes.

[0087] 3) The liquid in step 2) is placed in a high-pressure homogenizer with a pressure of 1500 bar and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com