Wave soldering device and its nozzle

A technology of wave soldering and nozzle openings, which is applied in the field of wave soldering devices and nozzles, can solve the problems of a large amount of high-temperature exhaust gas, increase cleaning costs, and material waste, and achieve the effects of reducing welding slag, saving equipment costs and energy, and being easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

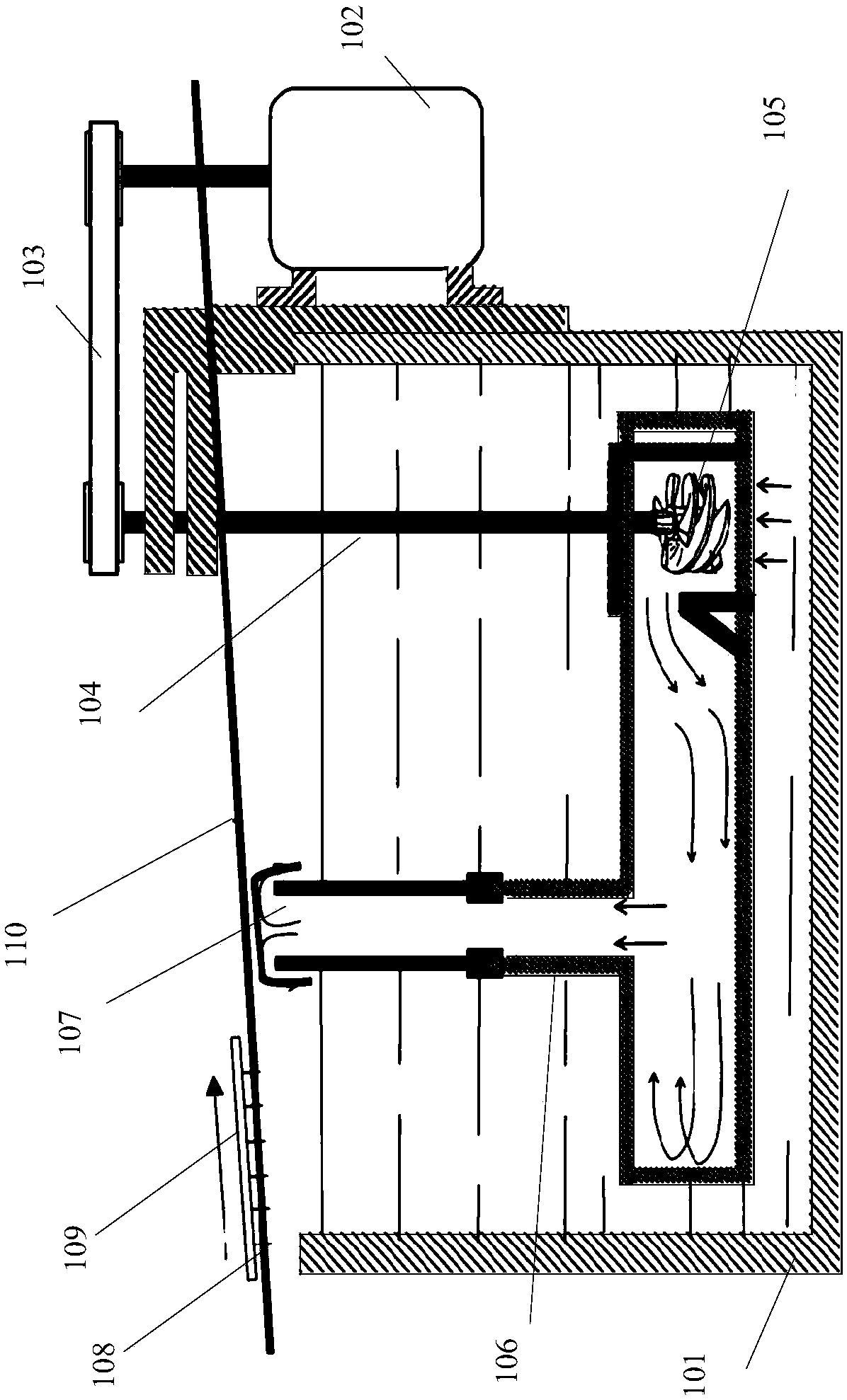

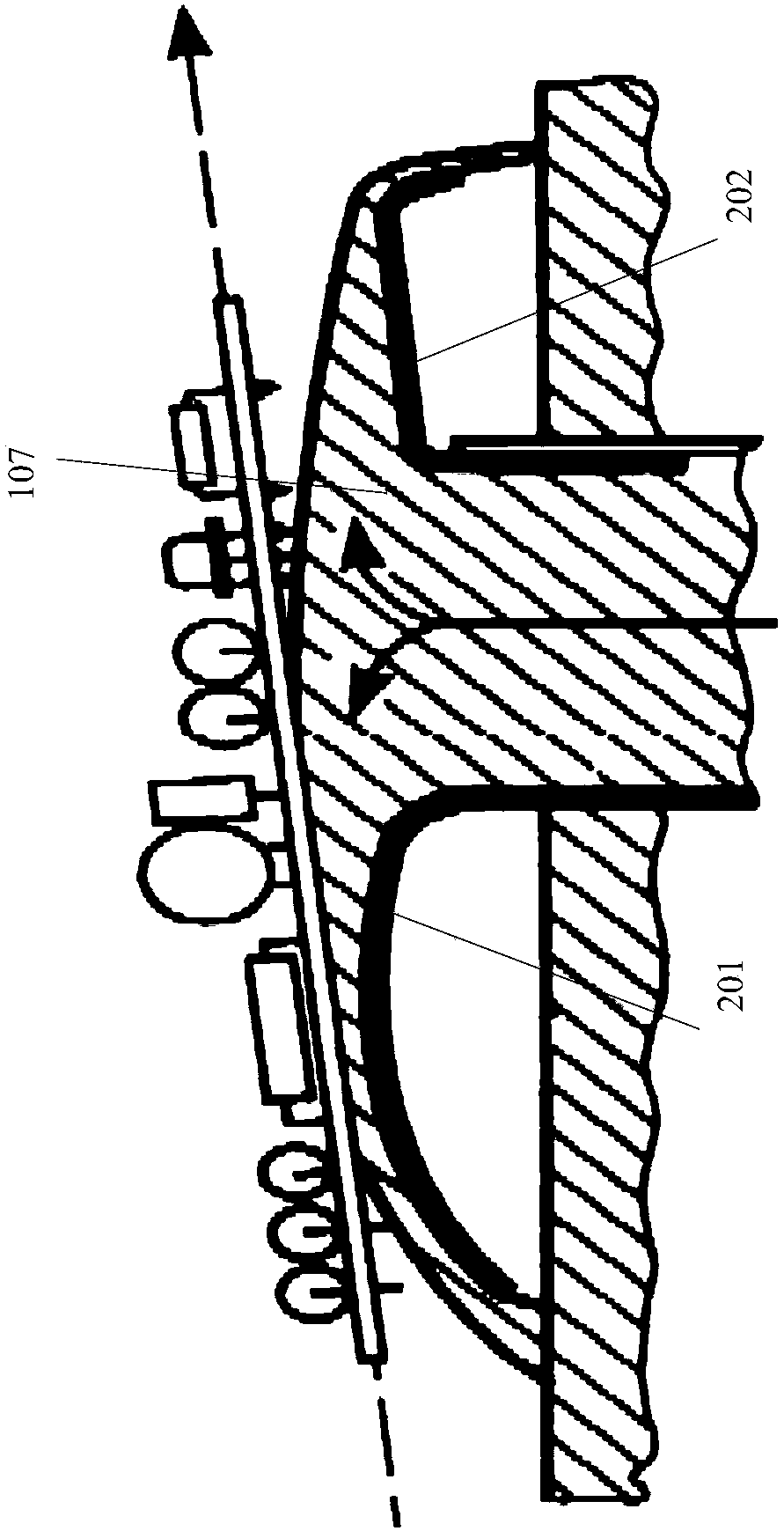

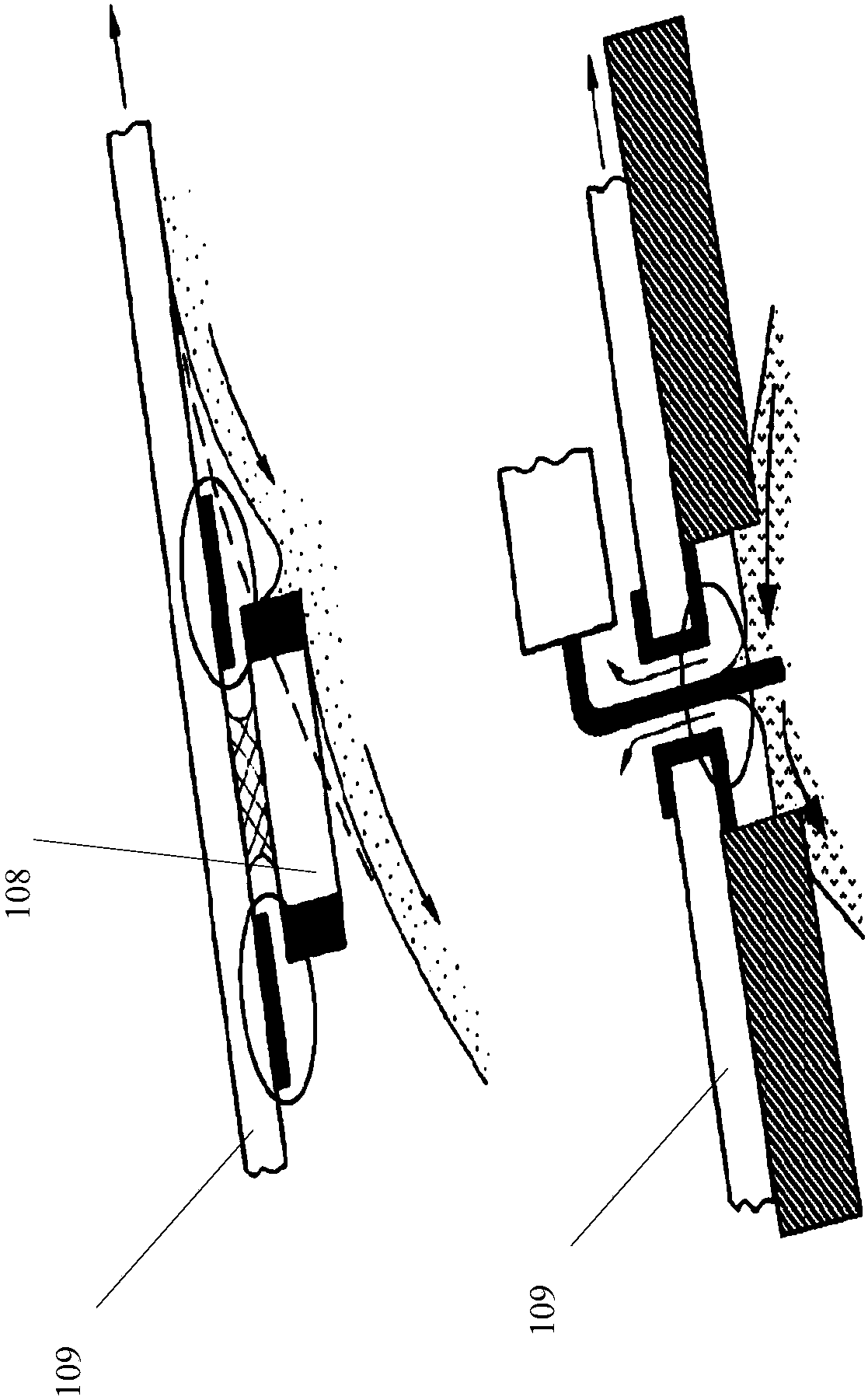

[0024] Now refer to Figure 5 , which shows a view of a wave soldering apparatus 500 according to an embodiment of the present invention. As shown in the figure, the wave soldering apparatus 500 includes: a solder pool 501, configured to store molten solder; a conveying device 502, configured to transport a circuit board to be soldered close to the solder pool; a pump device 503, configured to The molten solder in the solder pool is transported to the nozzle device through the delivery pipeline; the nozzle device 504 is configured to spray the molten solder to the circuit board close to the solder pool, wherein the nozzle device 504 includes at least one pair of adjacent branch The nozzle openings, the split nozzle openings are configured to spray the melted solder towards the middle direction between the split nozzle openings.

[0025] The solder pool 501 may be any existing or newly developed solder pool for wave soldering, for example, a solder pool with a cover according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com