A steel crane beam single-column expansion joint structure

A crane beam and expansion joint technology, applied in building structure, construction and other directions, can solve the problem that the rigid frame cannot fully play the load-bearing role, affect the construction progress, increase the construction cost, etc., achieve reasonable stress, speed up the construction progress, save money cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

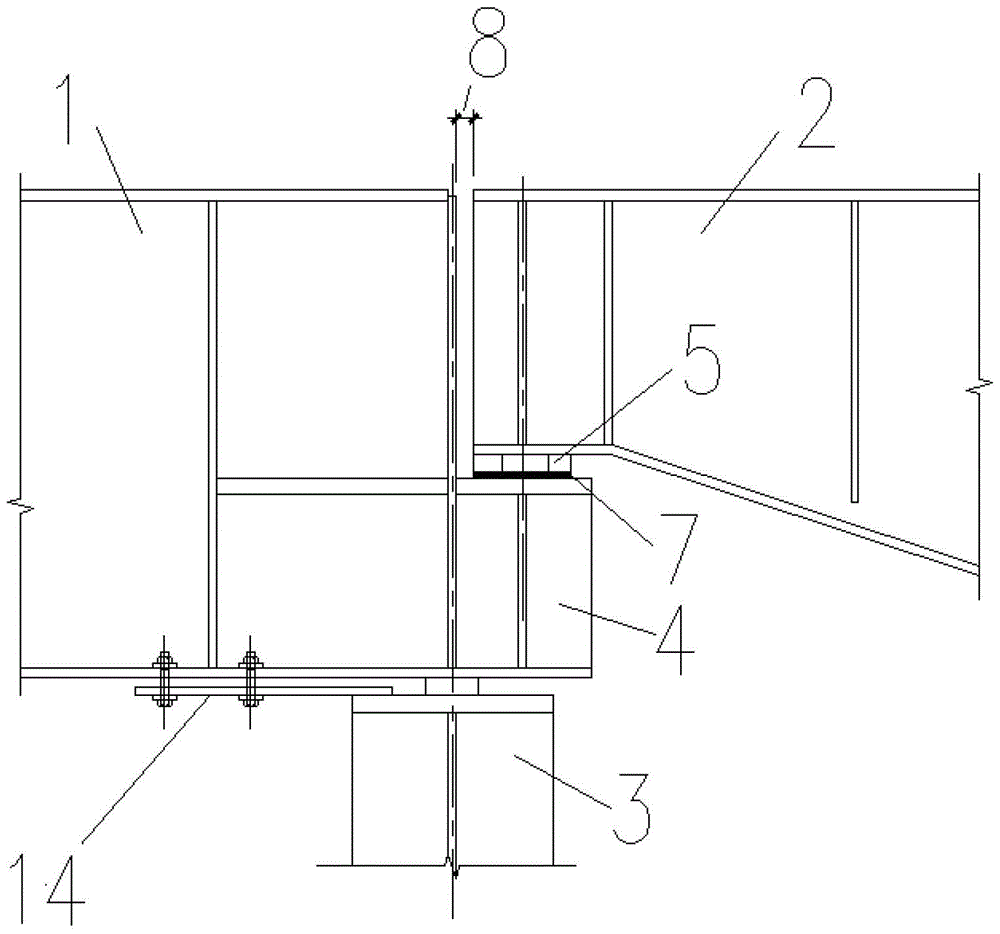

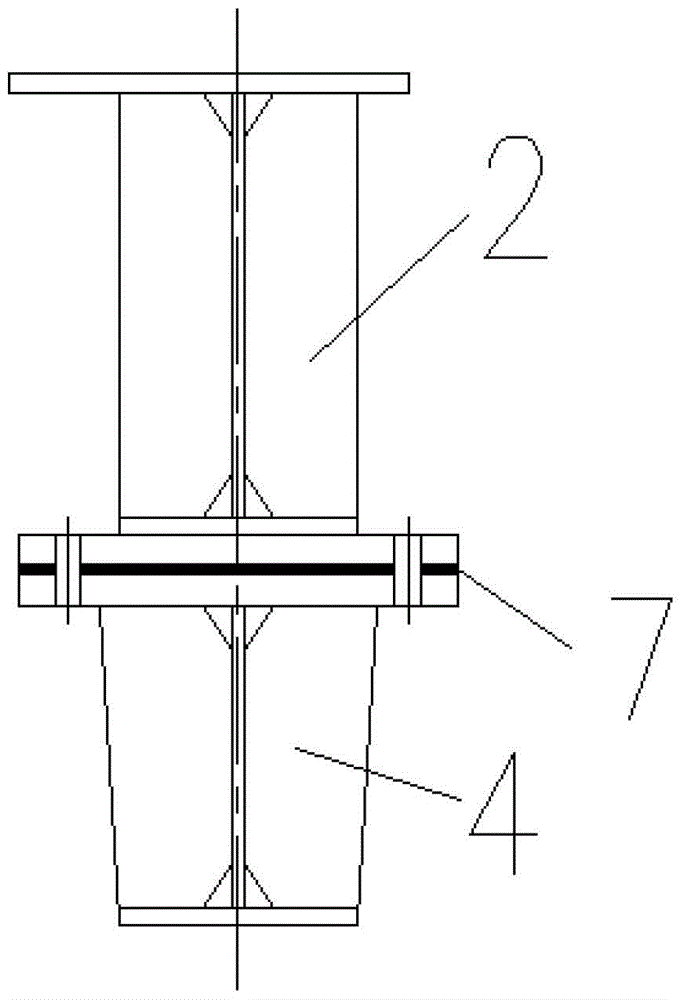

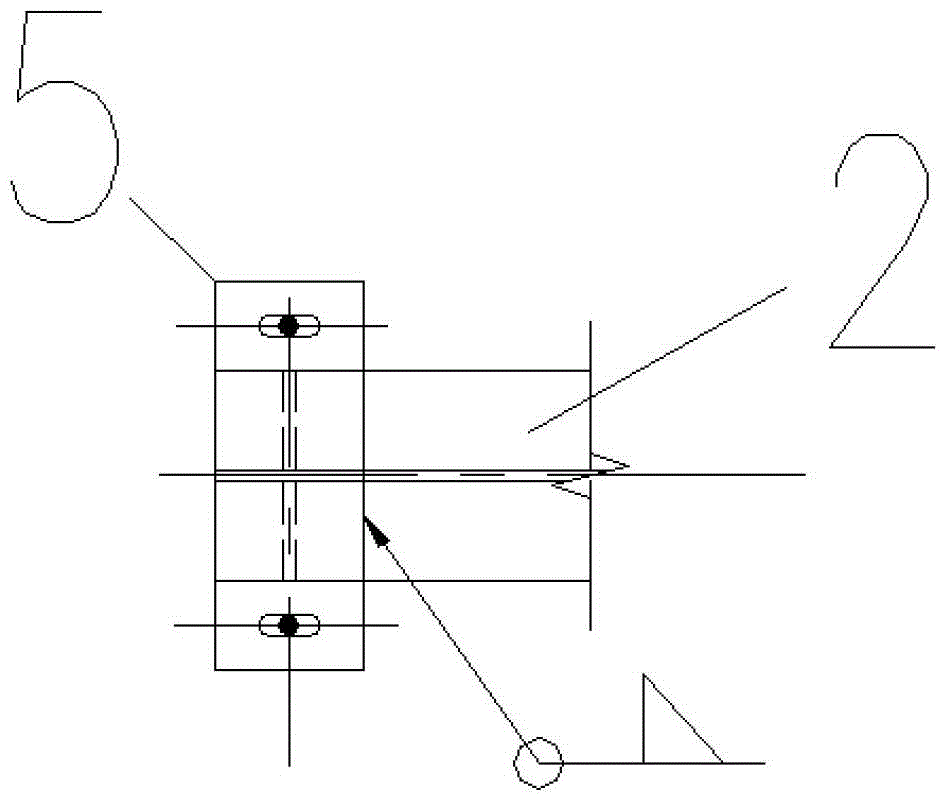

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 7 Shown, the present invention comprises left steel crane beam 1, right steel crane beam 2, rigid frame column 3, steel corbel 4, support plate 5, connecting steel plate 9; The frame column 3 is connected with a flat support 14; the upper parts of the left steel crane beam 1 and the right steel crane beam 2 are overlapped by connecting steel plates 9; one end of the right steel crane beam 2 is a variable section, and the lower flange of the variable section end Weld a support plate 5 that opens oblong hole, be connected on the steel corbel 4 that left steel crane girder 1 stretches out with bolt by this support plate 5.

[0023] In order to reduce friction, a polytetrafluoroethylene sintered plate 7 is placed under the support plate 5 .

[0024] The expansion joint 8 between the left steel crane beam 1 and the right steel crane beam 2 has a width of 30-50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com