Annular part inner diameter detection device

A detection device and a ring-shaped technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of high labor intensity, low labor efficiency, and high product cost for workers, and achieve the effects of easy automatic control, improved production efficiency, and reduced detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

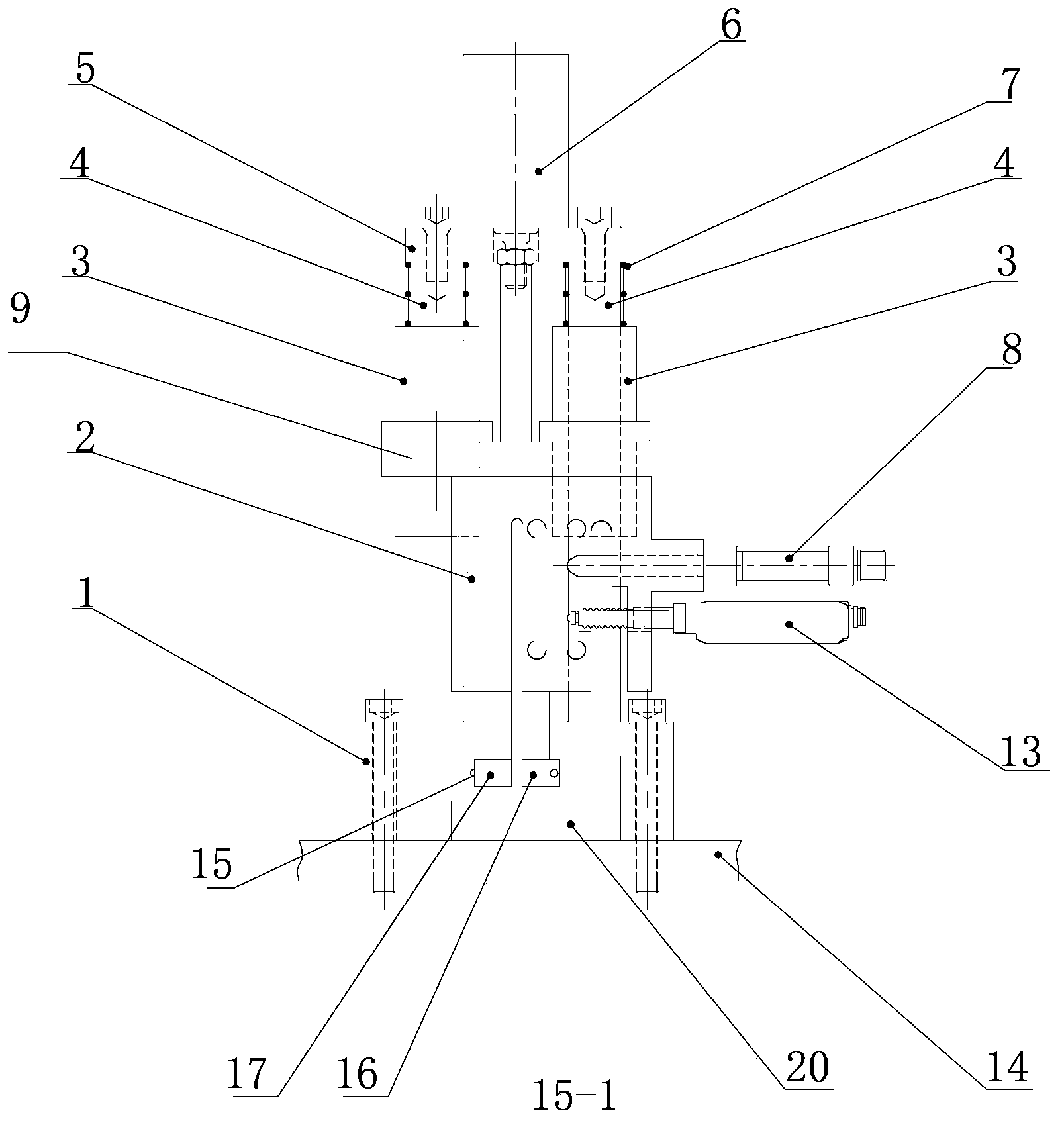

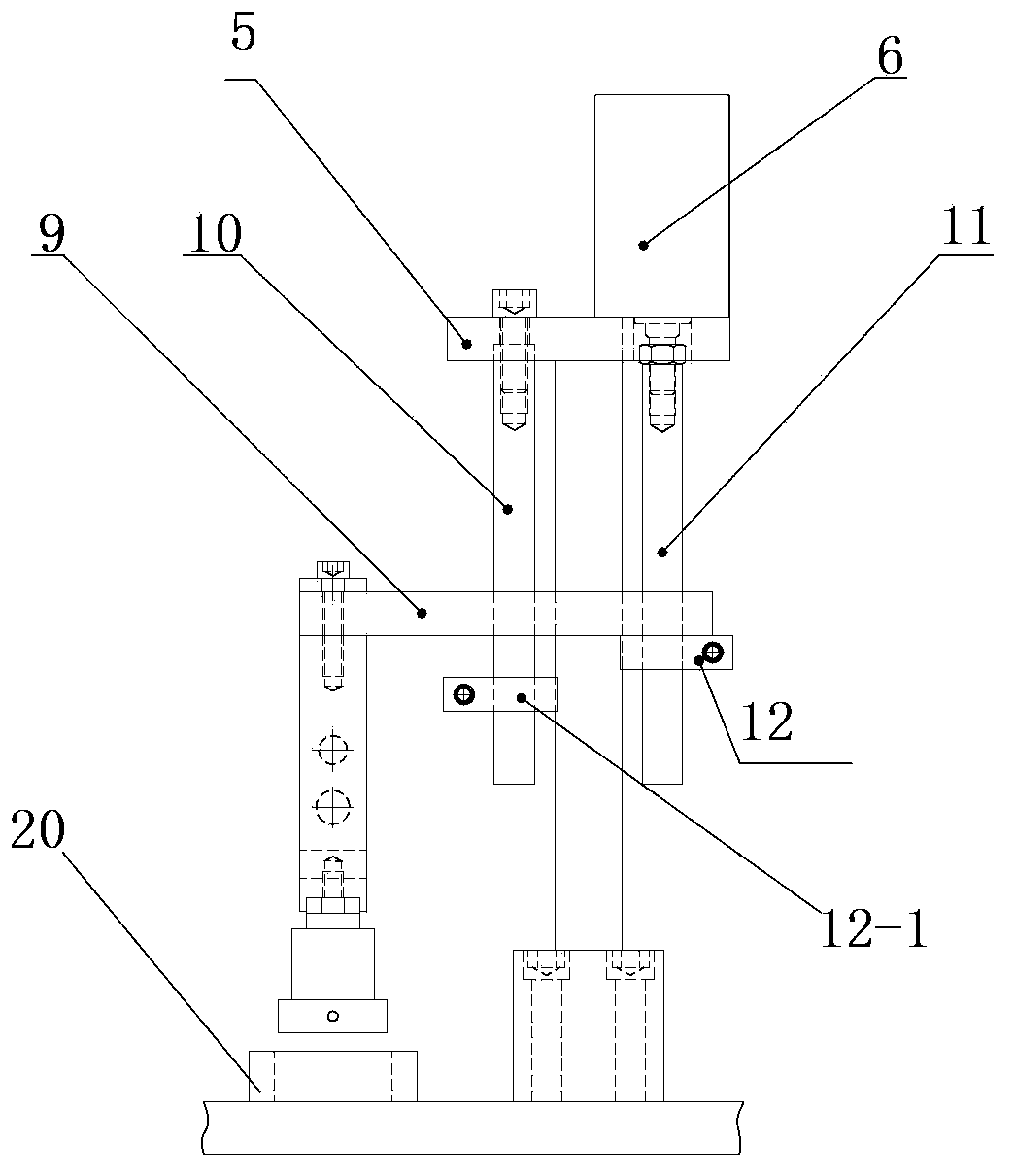

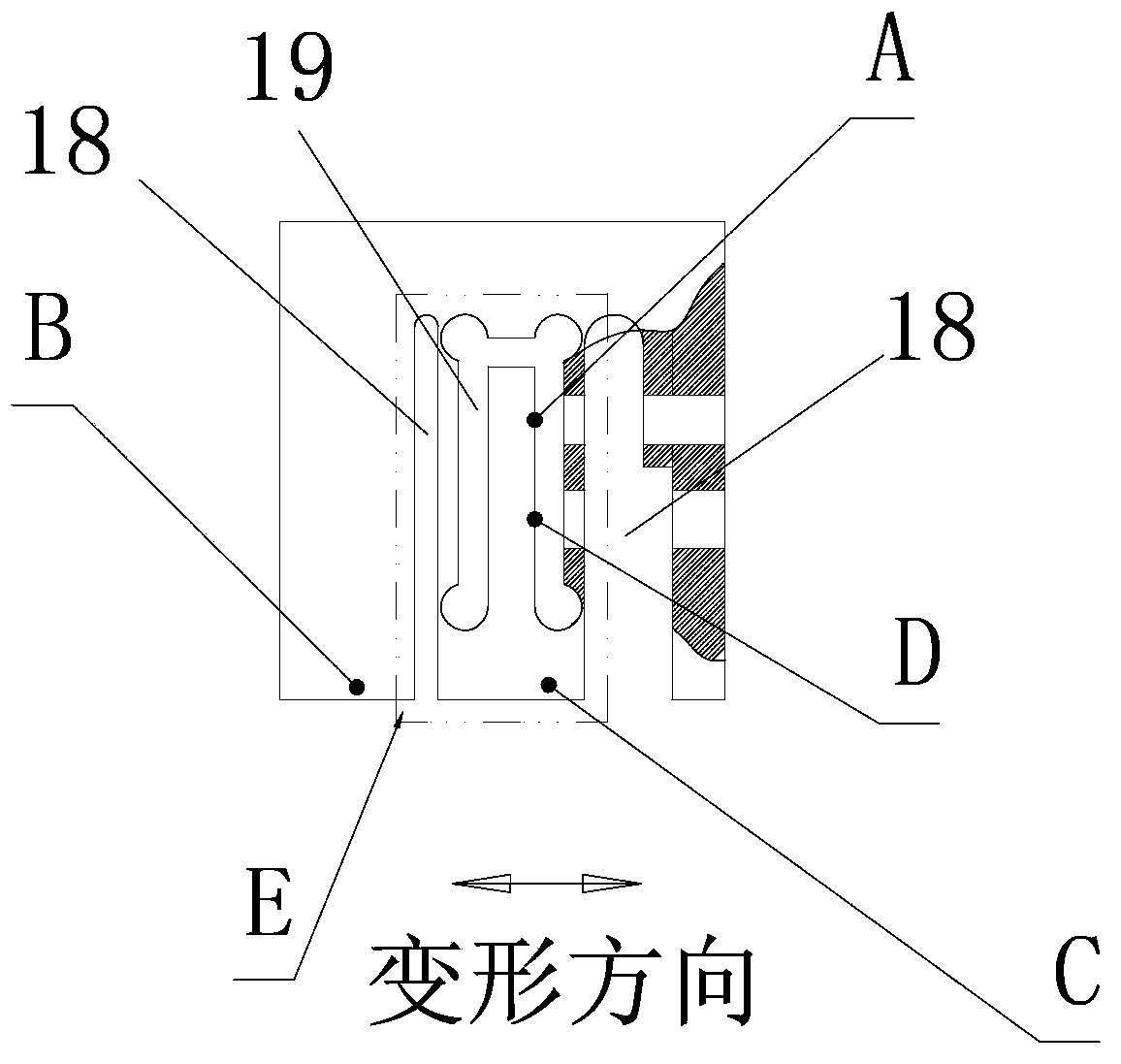

[0017] see attached Figure 1-3 , the present invention provides a kind of inner diameter detecting device of a circular ring part, comprising a base plate 14, a bracket 1, a movable plate 9, an up and down moving mechanism and an inner diameter measuring mechanism, the bracket is fixed on the base plate, and the bracket passes through the optical axis , The upper support plate is connected with the up and down moving mechanism, and the up and down moving mechanism is connected with the inner diameter measuring mechanism, and the inner diameter measuring mechanism includes elastic block 2, small cylinder 8, contact digital sensor 13, fixed measuring head 17 and movable measuring head 16 , the elastic block 2 is fixed on the movable plate 9; the small cylinder 8 and the contact digital sensor 13 are fixed on the side of the elastic block 2; the bottom surface B\C of the elastic block 2 is fixed with a fixed probe 17 and a movable measuring head Head 16. The up and down movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com