Annular part outer diameter detection device

A technology for circular parts and detection devices, applied in electromagnetic measurement devices, electric/magnetic diameter measurement, etc., can solve the problems of weakening the competitiveness of enterprises, high product costs, low labor efficiency, etc., and achieve easy automatic collection and reduce detection. cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

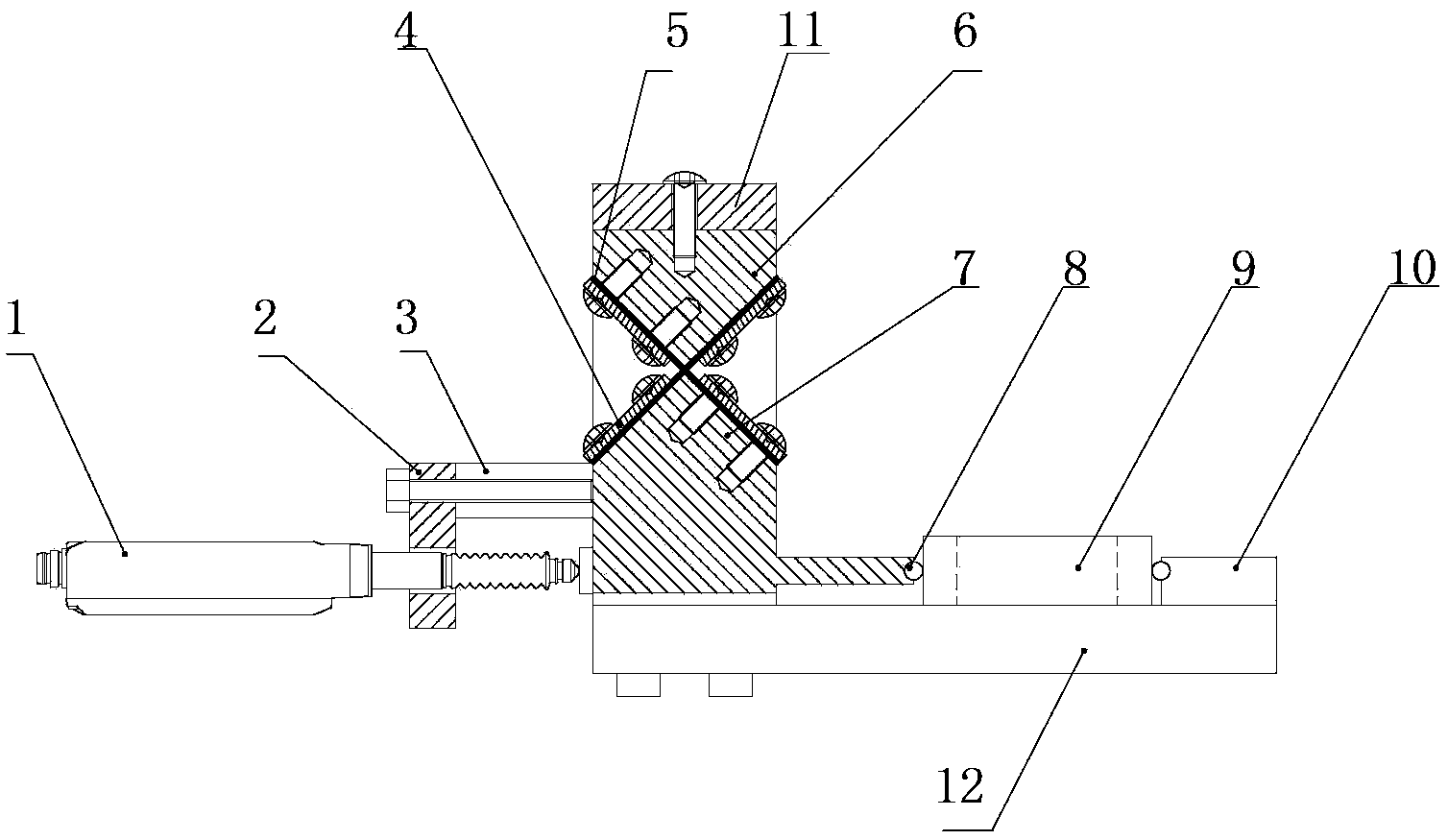

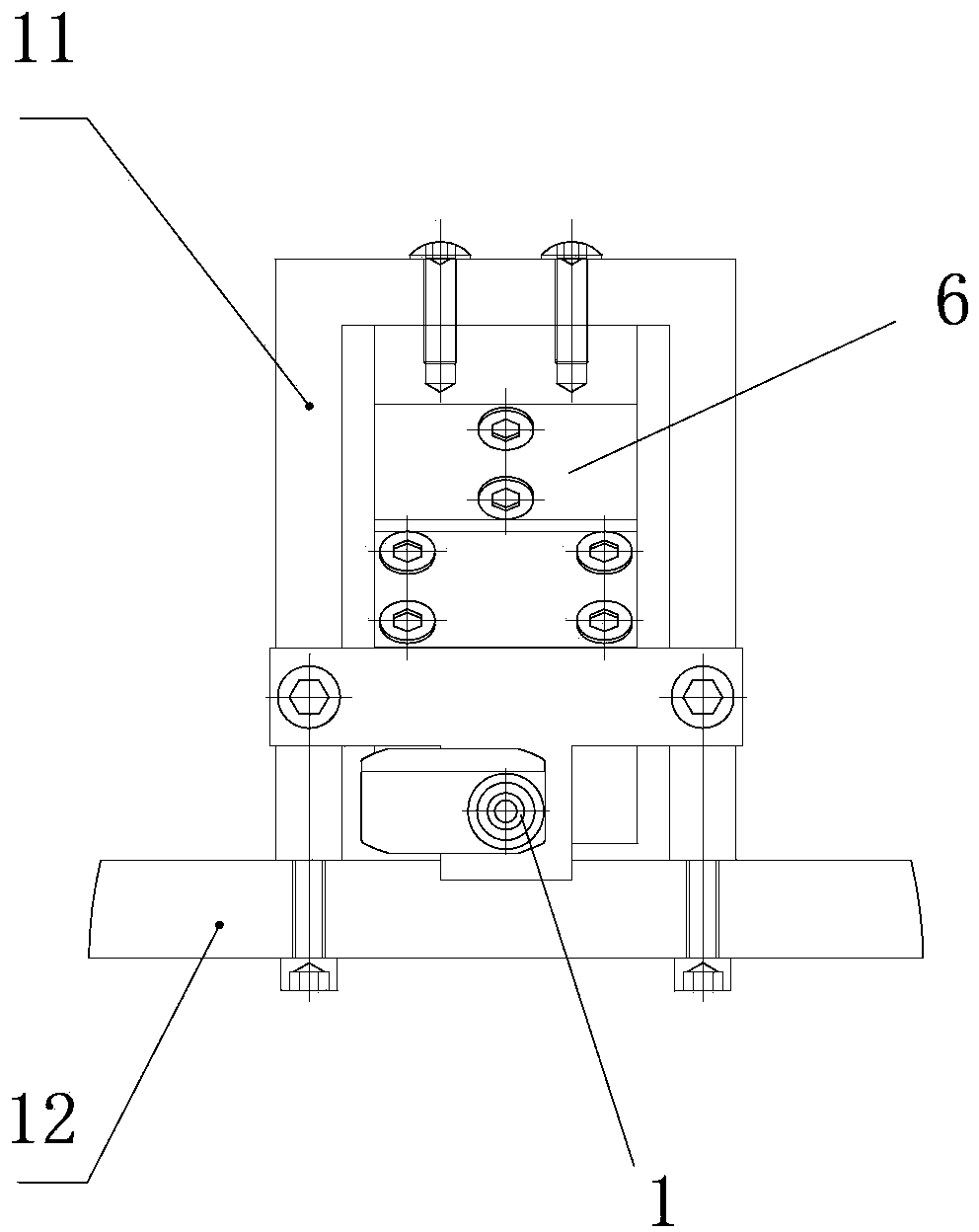

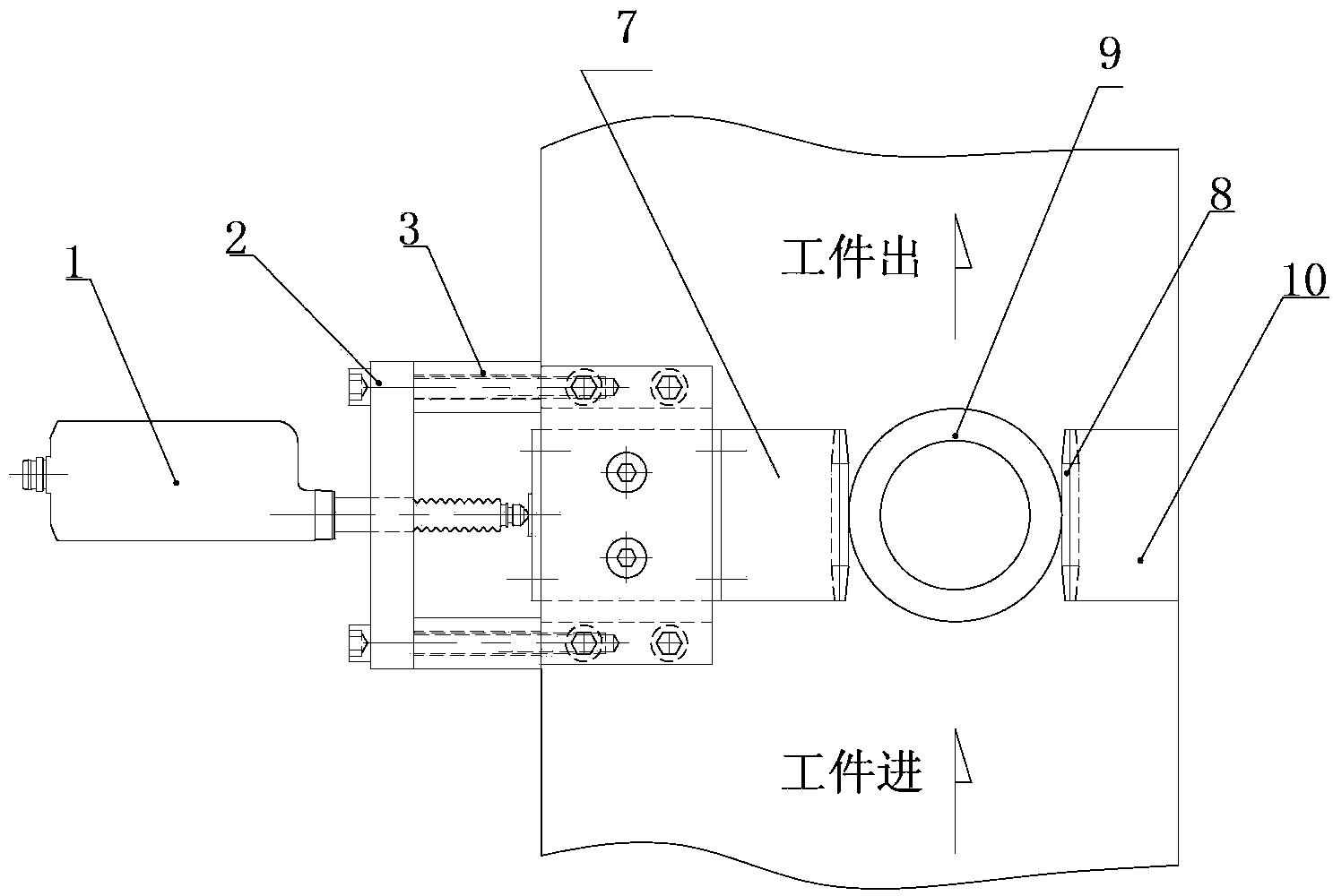

[0017] see attached Figure 1-3 , the present invention provides a device for detecting the outer diameter of circular parts, comprising a frame support 11, a contact digital sensor 1, a base plate 12, a sensor support 2, a positioning block 10 and a movable probe 7, the contact digital sensor and The sensor bracket is fixed, the sensor bracket is fixed on the frame bracket 11 through two parallel tubular brackets 3, the frame bracket is fixed on the bottom plate by screws, the contact digital sensor and the movable measuring head placed on the upper surface of the bottom plate Contact, the retractable stylus of the tactile digital sensor is in contact with the moving probe. The other end of the upper surface of the base plate is fixed to a positioning block, and the horizontal center of the positioning block and the movable measuring head are on the same level. The workpiece passes between the positioning block and the movable probe, and the movable probe pushes the workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com