A device and method for high-throughput research and preparation of iron-based powder metallurgy products

An iron-based powder metallurgy, high-throughput technology, applied in transportation and packaging, metal processing equipment, etc., can solve the problems of many variables in the performance of iron-based powder metallurgy products, complex influencing factors, and large intervals between test parameters. The effect of improving development efficiency, simplifying the process flow, and increasing the number of tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Iron-based powder metallurgy alloy (Fe-(0-0.1%) Mn-(0-1%) Ni-(0-0.8%) Mo-(0-1%) Cr-(0- 0.5%) C) optimization of components

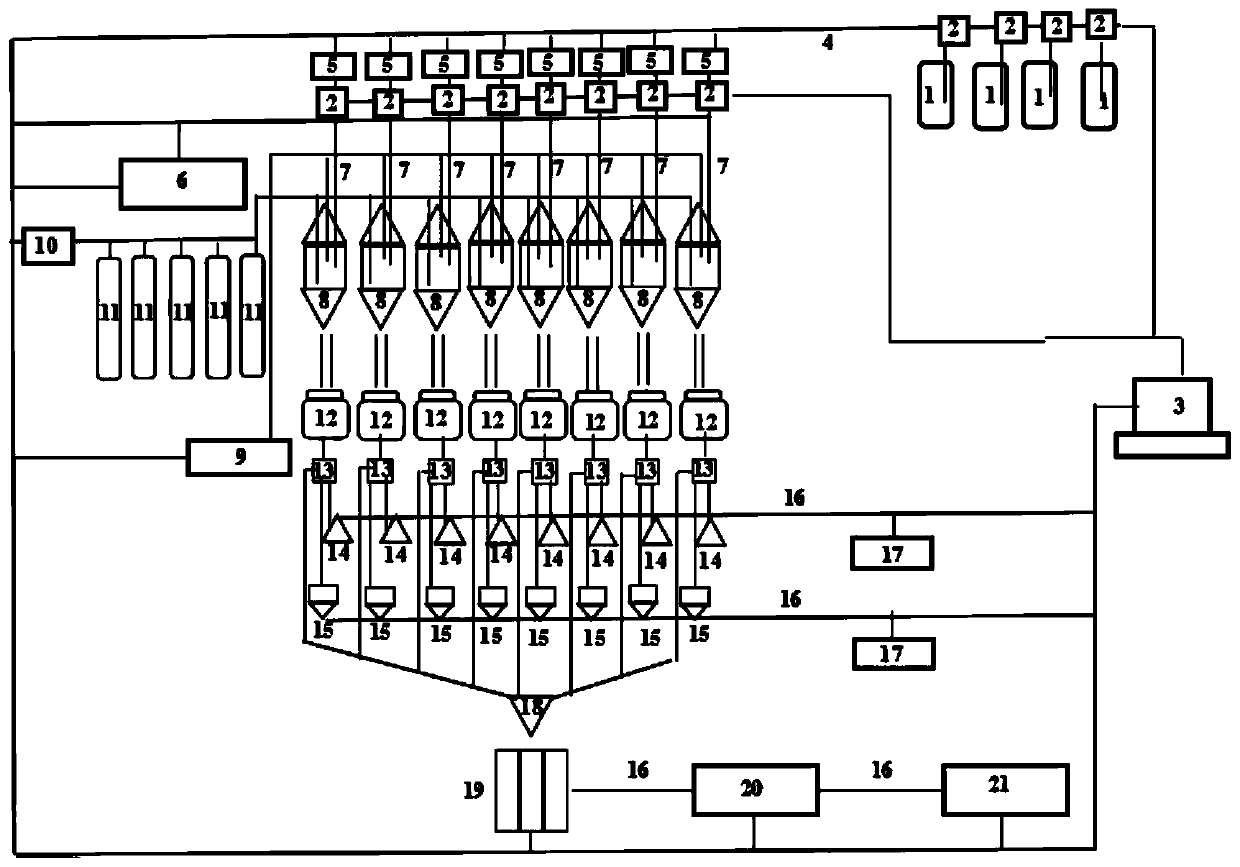

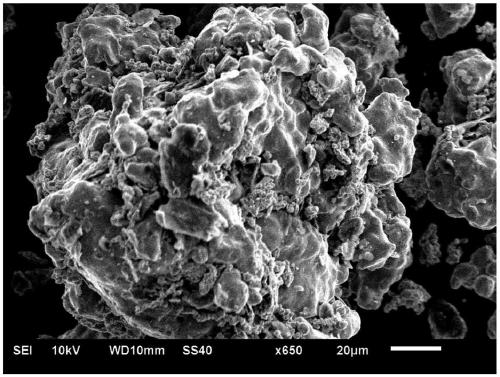

[0025]Using the same binder formula: ethylene bis stearamide 30%, microcrystalline wax 20%, palmitic acid 10%, stearic acid 20%, paraffin wax 15%, stearamide 1.5%, elaidic acid 2%, Heptadecanoic acid 1%, metallocene salt 0.4%, antioxidant stabilizer 0.1%. The weight percent content of the binder is 0.3%. Atomize pure iron powder (-5 Pa, the rotary speed of the conical mixer is 150 rpm, the bottom of the conical mixer is equipped with high-speed rotating blades, and the rotating speed of the blades is 500 rpm. The bonded iron-based powder obtained after mixing evenly enters different detection channels for powder performance and compaction performance analysis. The powder dust collection unit and the powder fluidity and bulk density collection unit are used to analyze the physical properties of the powder. The powder entering the m...

Embodiment 2

[0026] Embodiment 2: Iron-based powder metallurgical alloy (Fe-(0-0.1%) Mn-(0-1%) Ni-(0-0.8%) Mo-(0-1%) Cr-(0- 0.5%) C) optimization of components

[0027] Using the same binder formula: ethylene bis stearamide 30%, microcrystalline wax 20%, palmitic acid 10%, stearic acid 20%, paraffin wax 15%, stearamide 1.5%, elaidic acid 2%, 1% of heptadecanoic acid, 0.4% of metallocene salt, 0.1% of antioxidant stabilizer, and 0.3% by weight of binder. Atomize pure iron powder (-5 Pa, the rotary speed of the conical mixer is 100 rpm, the bottom of the conical mixer is equipped with high-speed rotating blades, and the rotating speed of the blades is 400 rpm. The bonded iron-based powder obtained after mixing evenly enters different detection channels for powder performance and compaction performance analysis. The powder dust collection unit and the powder fluidity and bulk density collection unit are used to analyze the physical properties of the powder. The powder entering the middle ma...

Embodiment 3

[0028] Embodiment 3: binding agent (ethylene bis stearamide 20%~50%, microcrystalline wax 15%~25%, palmitic acid 5%~20%, stearic acid 5%~20%, paraffin 5%~ 10%, stearamide 0.5%~2%, elaidic acid 0.1%~2%, heptadecanoic acid 0.1%~1%, metallocene salt 0.2%~1%, add a small amount of antioxidant 1680.1%~2% ) formulation optimization

[0029] Use the same iron-based alloy composition: Fe-0.1Mn-1Ni-0.8Mo-1Cr-0.5C to water atomize pure iron powder (-5 Pa, the rotary speed of the conical mixer is 120 rpm, the bottom of the conical mixer is equipped with high-speed rotating blades, and the rotating speed of the blades is 600 rpm. The bonded iron-based powder obtained after mixing evenly enters different detection channels for powder performance and compaction performance analysis. The powder dust collection unit and the powder fluidity and bulk density collection unit are used to analyze the physical properties of the powder. The powder entering the middle shoe is pressed on a fully auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com