Seed producing summer squash harvester

A technology of harvester and zucchini, applied in the field of seed zucchini harvester, can solve the problems of low practical and popularization value, large loss of gourd, loss of growers, etc., and achieves improvement of mechanized harvesting efficiency and yield, structure and transmission mode Reasonable and prolong the effect of the running process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

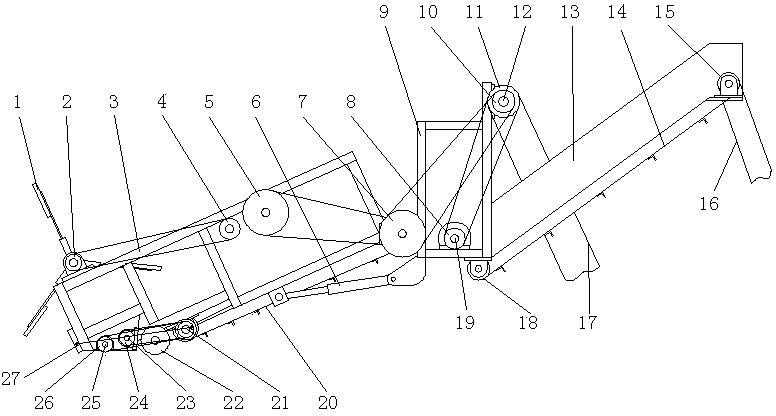

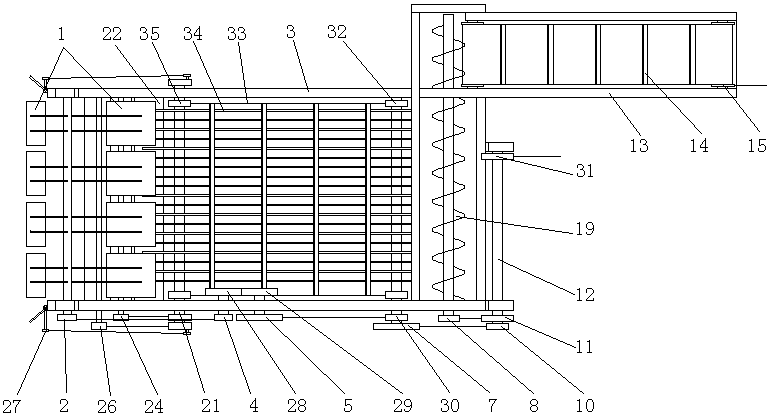

[0025] A seed beating zucchini harvester is installed at the front end of the tractor, a seed remover is installed at the rear of the tractor, and the front end of the tractor is the front end of the device.

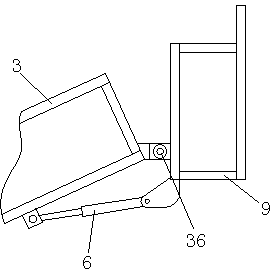

[0026] Such as figure 1 Shown in -6, there is a bolt hole connected to the tractor below the feeding screw frame 9, and the feeding screw frame is connected with the tractor front end by bolts, and the main frame 3 right-hand side is hinged with the feeding screw frame by hinge 36. A lift cylinder 6 is hinged between the spiral frame and the main frame, and the lift cylinder communicates with the oil pump on the tractor. This device can be lifted by the lift cylinder when the tractor with the zucchini harvester and seed remover is installed.

[0027] Both sides of the main frame front end are equipped with a melon pulling device 27, and the melon pulling device is composed of a hinge 27-1 fixedly installed on both sides of the main frame front end, a melon pulling plate ...

Embodiment 2

[0037] On the basis of Embodiment 1, the tractor output pulley that drives the main transmission shaft 12 to rotate is changed into a hydraulic motor, the hydraulic motor is connected with the oil pump of the tractor, and the oil pump of the tractor drives the hydraulic motor to rotate, and a pulley is installed on the output shaft of the hydraulic motor. The main transmission shaft 12 is driven to rotate by the belt pulley and the belt I17 on the output shaft of the hydraulic motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com