Waterproof insulation layered composite fabric

A technology of composite fabrics and thermal insulation layers, applied in the field of textile fabrics, can solve the problems of wet thermal clothing, failure to keep the body warm, and discomfort, etc., and achieve the effect of ensuring thermal insulation, good thermal insulation effect, and good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

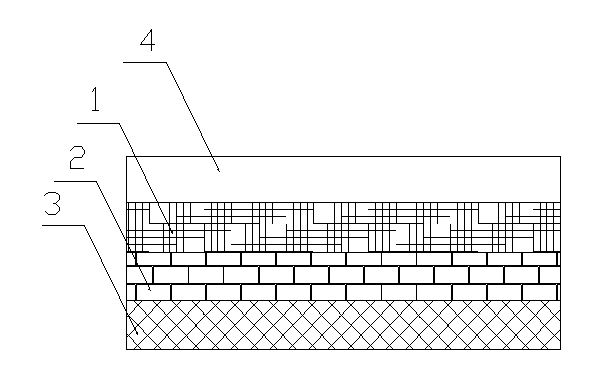

[0016] See figure 1 The present invention relates to a waterproof and warmth-preserving layered composite fabric, which in turn includes an outer layer 1, a middle layer 2, and an inner layer 3. The outer layer 1 and the middle layer 2 are pressed together, and the outer layer 1 is a windproof, waterproof and breathable membrane, The layer 3 is a thermal insulation layer, and the inner layer 3 is attached to the middle layer 2.

[0017] The windproof, waterproof and breathable membrane is a microporous polyurethane membrane.

[0018] The microporous pore diameter of the microporous polyurethane membrane is 100-500 microns.

[0019] The outer layer 1 is also provided with a protective layer 4, and the protective layer 4 is a polyvinylidene fluoride sprayed film.

[0020] The middle layer is made of fabric, and the fabric includes an anti-wetting layer. The specific structure is: an anti-wetting layer and a napping layer are compounded on the upper and lower surfaces of the anti-wettin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com