A heat-sensitive organic compound heating and melting device

An organic compound, melting device technology, applied in the direction of heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of violation of clean and civilized production, failure to meet the requirements of use, discoloration of curing agents, etc. Compact, avoids degradation, easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

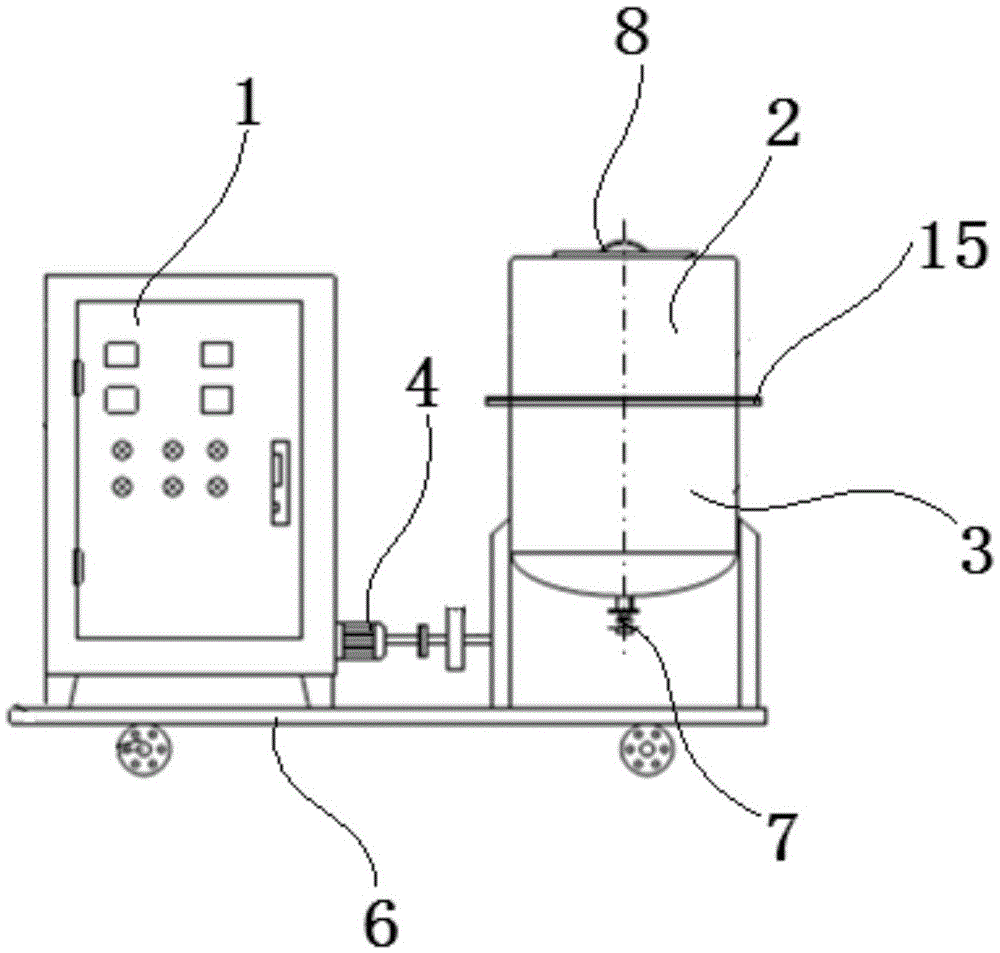

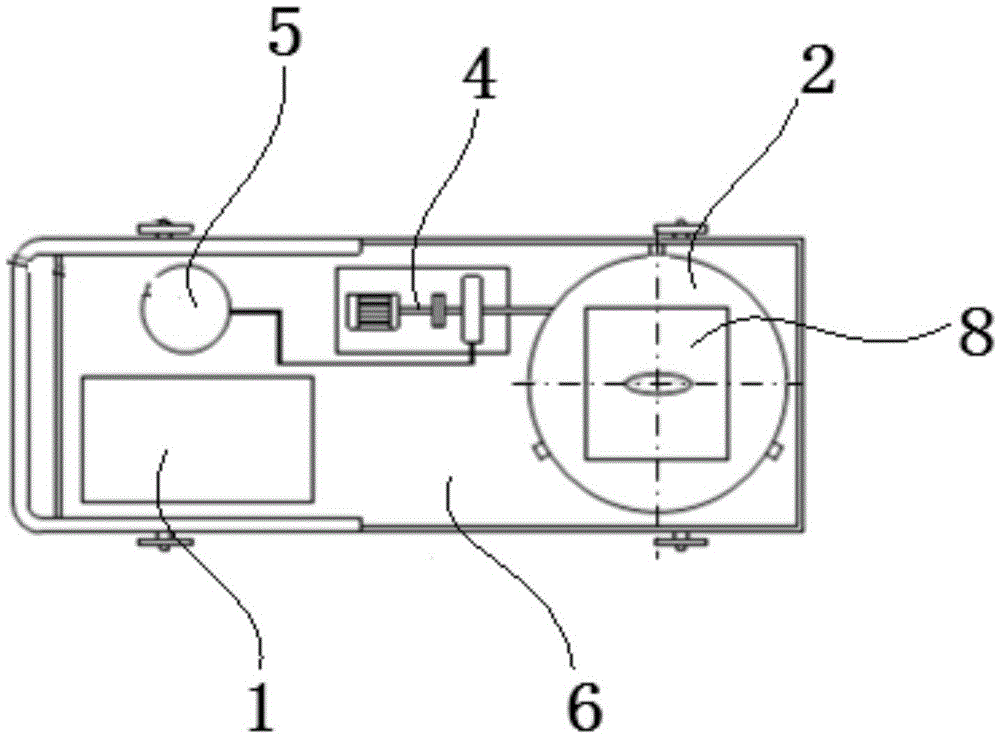

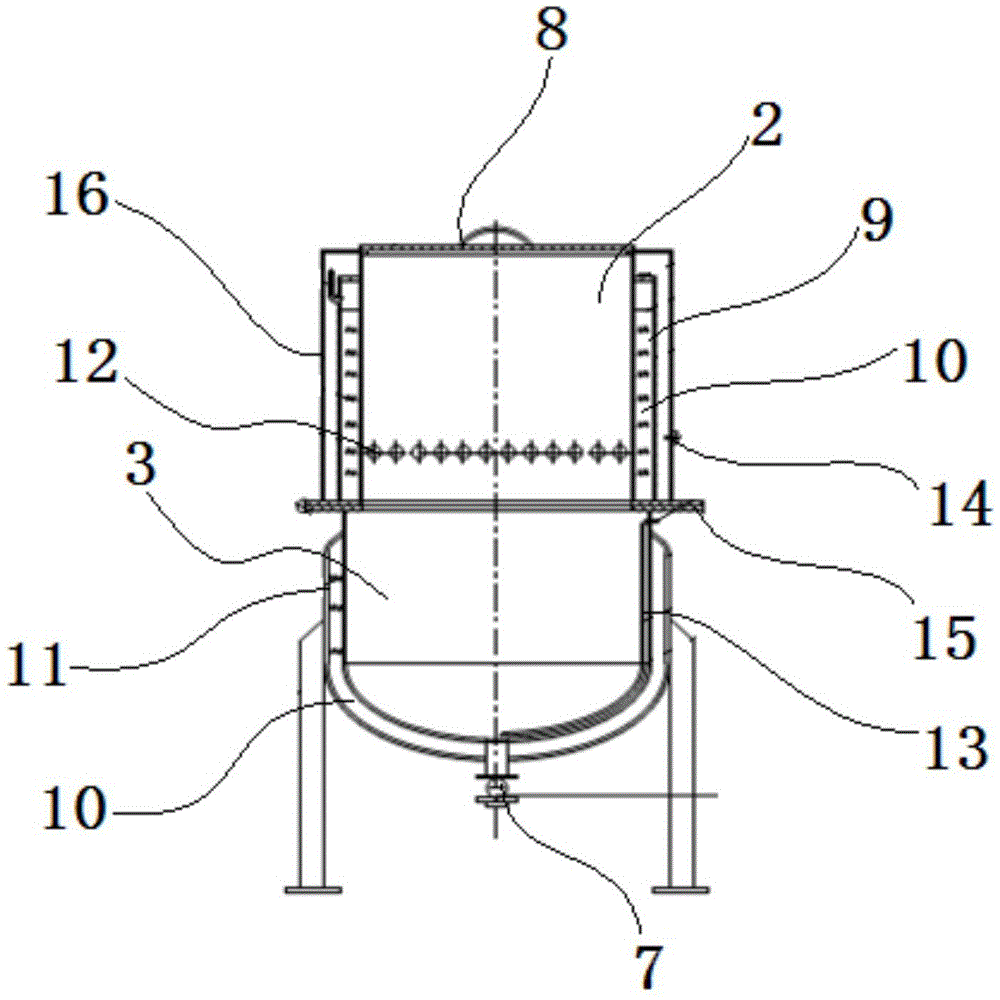

[0028] see Figure 1 to Figure 3 As shown, in this embodiment, a heat-sensitive organic compound heating and melting device includes an electric control box 1, a heating and melting furnace 2, a holding furnace 3, a heat-conducting oil pump 4 and a heat-conducting oil furnace 5, the electric control box 1, the heating and melting furnace 2. The holding furnace 3, the heat-conducting oil pump 4 and the heat-conducting oil furnace 5 are collectively assembled on the mobile cart 6. The heating and melting furnace 2 communicates with the holding furnace 3 and is arranged above the holding furnace 3. The holding furnace 3 The bottom of the heating and melting furnace 2 is provided with a discharge port 7, and the top of the heating and melting furnace 2 is provided with a top cover 8. The furnace body of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com