Automatic feeding device of edging machine

A technology of automatic feeding and turning machine, which is applied in the direction of automatic in/out of workpieces, automatic/semi-automatic lathes, turning equipment, etc. The effect of production efficiency, speeding up the loading and unloading steps, and saving the time of material loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

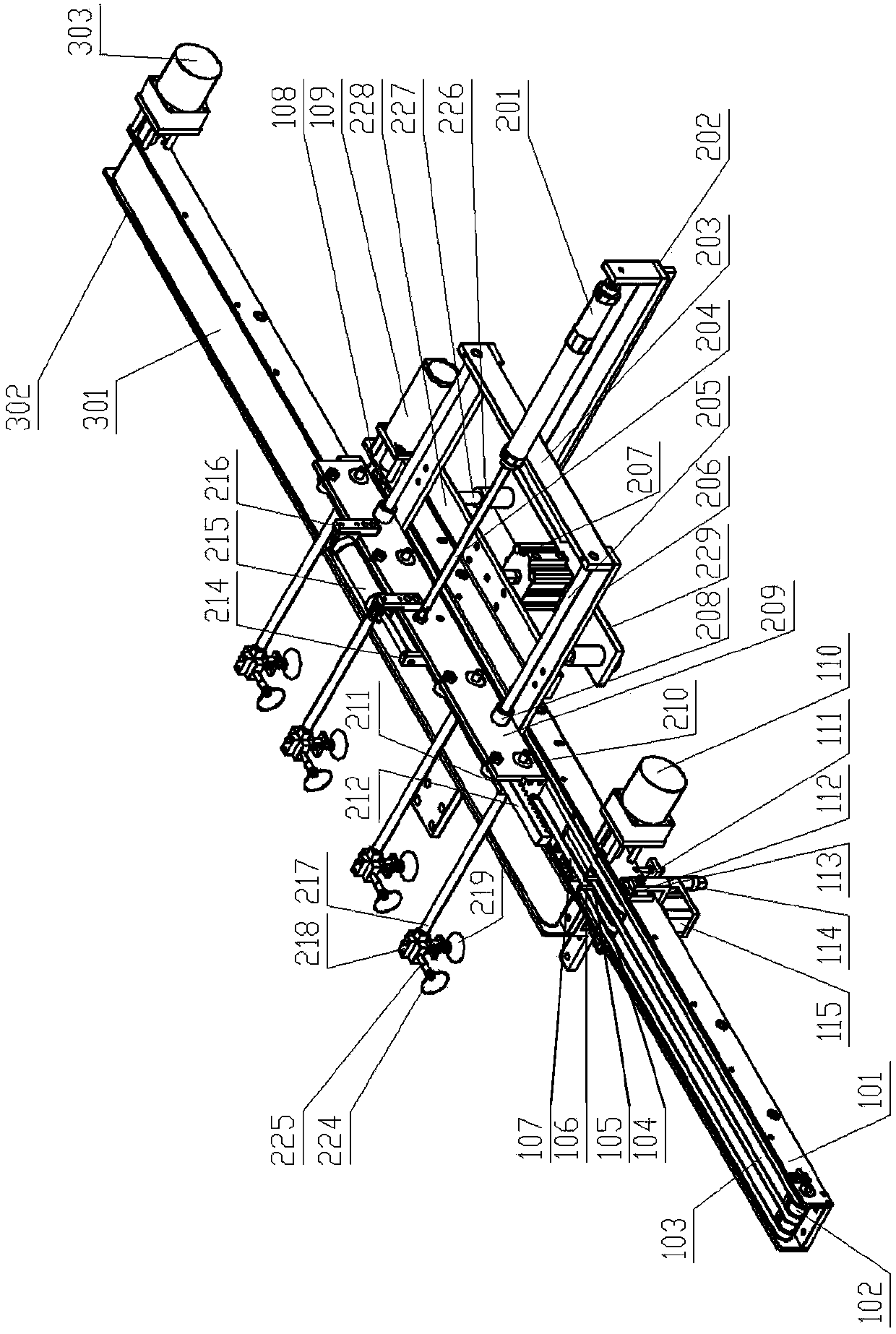

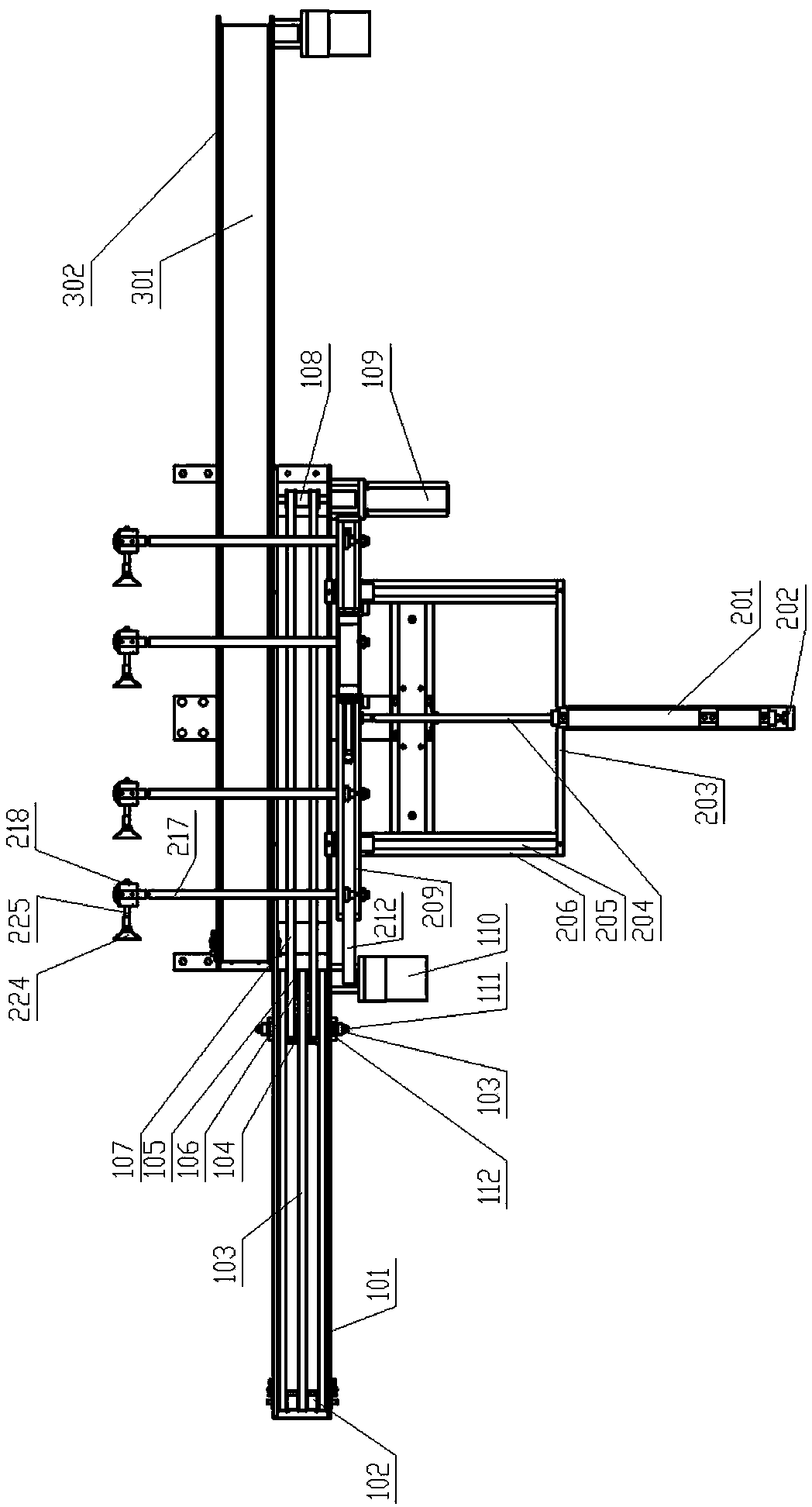

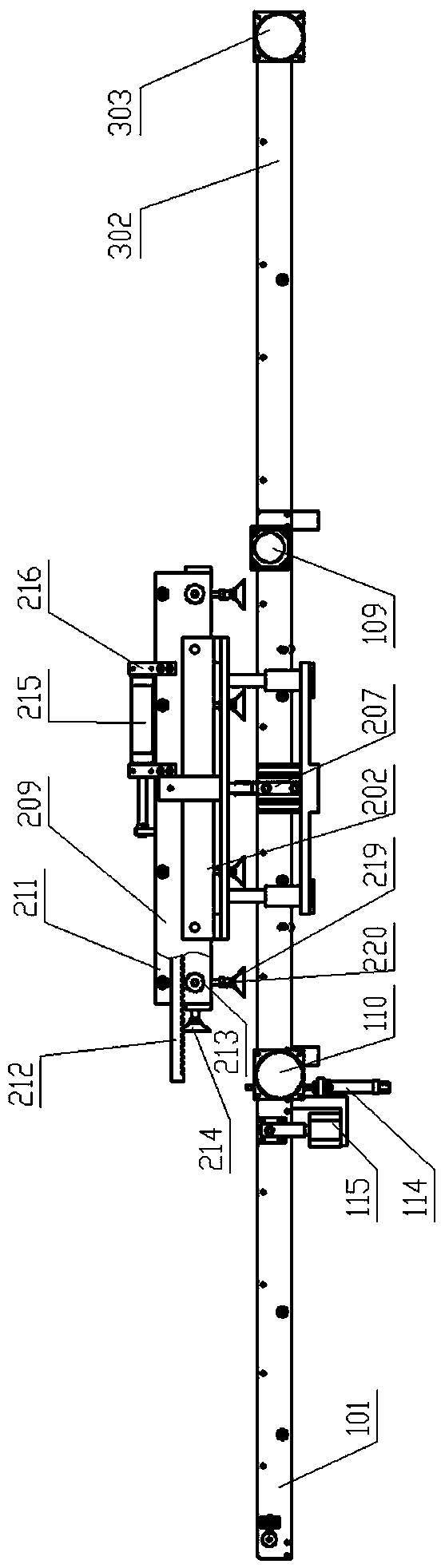

[0023] The automatic feeding device of the edge turning machine includes an input mechanism, a loading and unloading structure and an output mechanism.

[0024] The input mechanism includes a first input belt set 103 , a first conveying asynchronous motor 110 , a second input belt set 107 and a second input belt synchronous motor 109 .

[0025] Such as figure 1 , figure 2 and image 3 As shown, the first input belt set 103 is composed of a set of first input belts arranged at intervals and parallel to each other. The two ends are respectively provided with a first driving shaft 105 and a first driven shaft 102. The first driving shaft 105 and the second A conveying asynchronous motor 110 is matched and connected. The first conveying asynchronous motor 110 is fixedly arranged on the input belt baffle plate 101 . The first conveying asynchronous motor 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com