Automatic assembling device

An automatic assembly and equipment technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as obstacles to the development of automation equipment, assembly position deviation and misalignment, and inaccurate product calibration, so as to avoid manual repetitive actions and speed Fast, overcoming the effect of cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

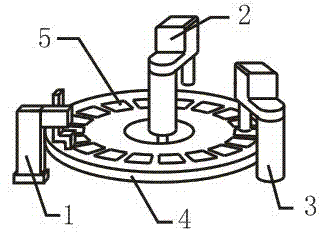

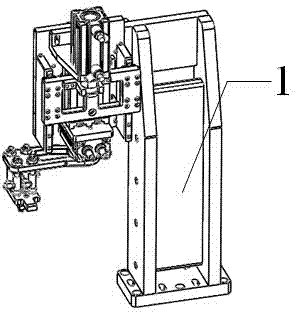

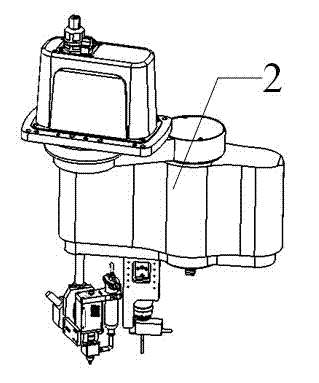

[0014] Automatic assembly equipment, including a pressure head mechanism 1, a dispensing mechanism 2, an assembly mechanism 3, a disc mechanism 4, and a jig 5. It is characterized in that the pressure head mechanism 1 is set on the side of the disk mechanism 4, and the assembly mechanism 3 is set On the other side of the disk mechanism 4, the dispensing mechanism 2 is arranged in the middle of the disk mechanism 4, and a through hole is arranged in the middle of the disk mechanism 4, and the disk mechanism 4 can rotate along the through hole. The jigs 5 are radially arranged on the disc mechanism 4 . A vacuum suction nozzle is arranged on the pressure head mechanism 1 . The pressure head mechanism 1, the dispensing mechanism 2, and the assembly mechanism 3 are controlled by CCD sensors. The jig 5 is provided with a pressure device, which can be pressed together under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com