Grinding control system of building roof

A control system and top wall technology, applied in the direction of automatic grinding control devices, grinding machines, manufacturing tools, etc., can solve the problems of adverse effects of construction equipment on construction workers, difficulty in sealing and collecting protective devices, and easy generation of large dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

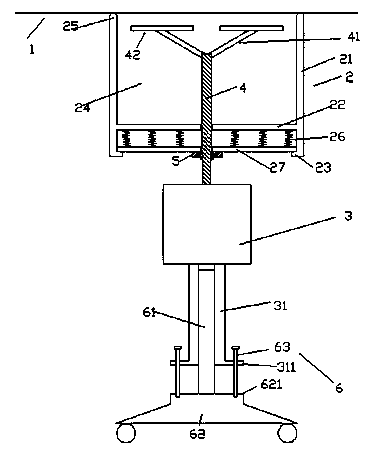

[0018] Combine below Figure 1-3 The present invention will be described in detail.

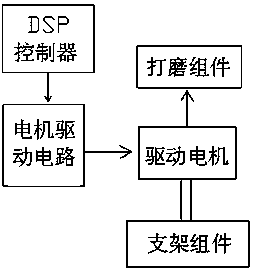

[0019] A kind of building top wall polishing control system, comprises polishing assembly 2, DSP controller, motor driving circuit, driving motor 3 and bracket assembly 6, and DSP controller controls the rotation of driving motor 3 through motor driving circuit, wherein, driving motor 3 and The grinding assembly 2 is connected to drive the grinding assembly 2 to run, the grinding assembly 2 is used to perform grinding processing, and the bracket assembly 6 is used to carry the grinding assembly 2 and the drive motor 3,

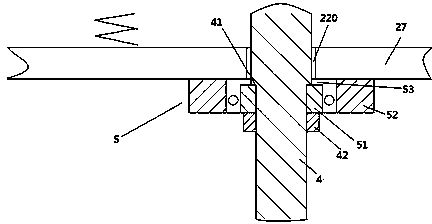

[0020] Wherein, the grinding assembly 2 includes an outer cover, and the outer cover includes an integrally formed side wall 21 and a bottom wall 22, the side wall 21 and the bottom wall 22 surround and form an outer cover inner cavity 24, and the outer cover inner cavity 24 is used to accommodate the rotating grinding head 42, and The upper end of the outer cover cavity 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com