An armrest of a high pressure-resistant car seat

A car seat, high pressure technology, applied in the direction of vehicle seats, armrests, vehicle parts, etc., can solve the problems of disconnection between armrests and supports, easily damaged armrests, weak supports, etc. Simple structure and the effect of strengthening the pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

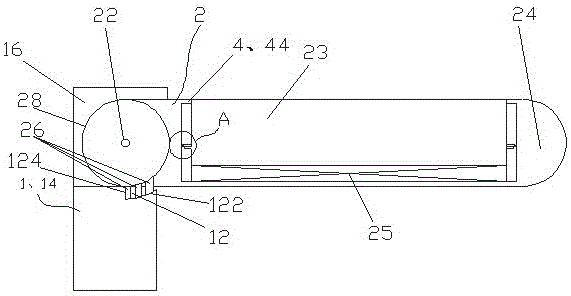

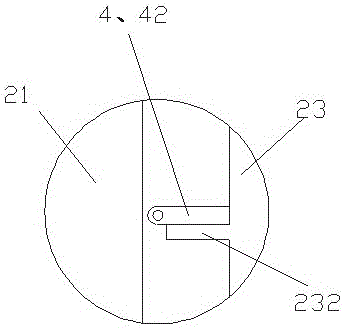

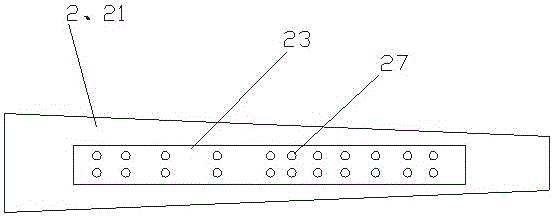

[0033] like Figure 1-4 As shown, a high-pressure-resistant car seat armrest, the seat includes a support 1 positioned at the side, the armrest includes a vertically long armrest body 2, and one end of the armrest body 2 is rotatably arranged on the support 1, and the rotating shaft 22 level, and the other end is the free end 24 that can rotate synchronously. On the armrest body 2, three support members 26 are sequentially arranged between the rotating shaft 22 and the free end 24. The support 1 is provided with a seat groove 12 located below the armrest, and all the support members 26 are adapted to the seat groove 12 as a whole. And with the rotation of the armrest body 2, it can enter and move out of the seat groove 12. The seat groove 12 includes a groove bottom 122 supporting the support member 26 and a groove wall 124 that can cooperate with the support member 26 to block the armrest from turning downward and to the rear of the seat. When the main body 2 is rotated to t...

Embodiment 2

[0040] like Figure 2-5 As shown, a high-pressure automobile seat armrest differs from Embodiment 1 in that the bottom 122 of the seat groove 12 is a horizontal plane, and the supporting member 26 is a spring foot. At this time, the support member 26 can smoothly enter and exit the seat groove 12, and the horizontal plane of the groove bottom 122 is conducive to stably supporting the main body of the armrest in a horizontal state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com