Hydrofoil folding vessel

A technology for folding boats and hydrofoils, which is applied in the directions of foldable/inflatable hulls, hulls, and salvage of boats, can solve the problems of thin hull structure, insufficient hull rigidity, poor stability, etc. The effect of structural stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

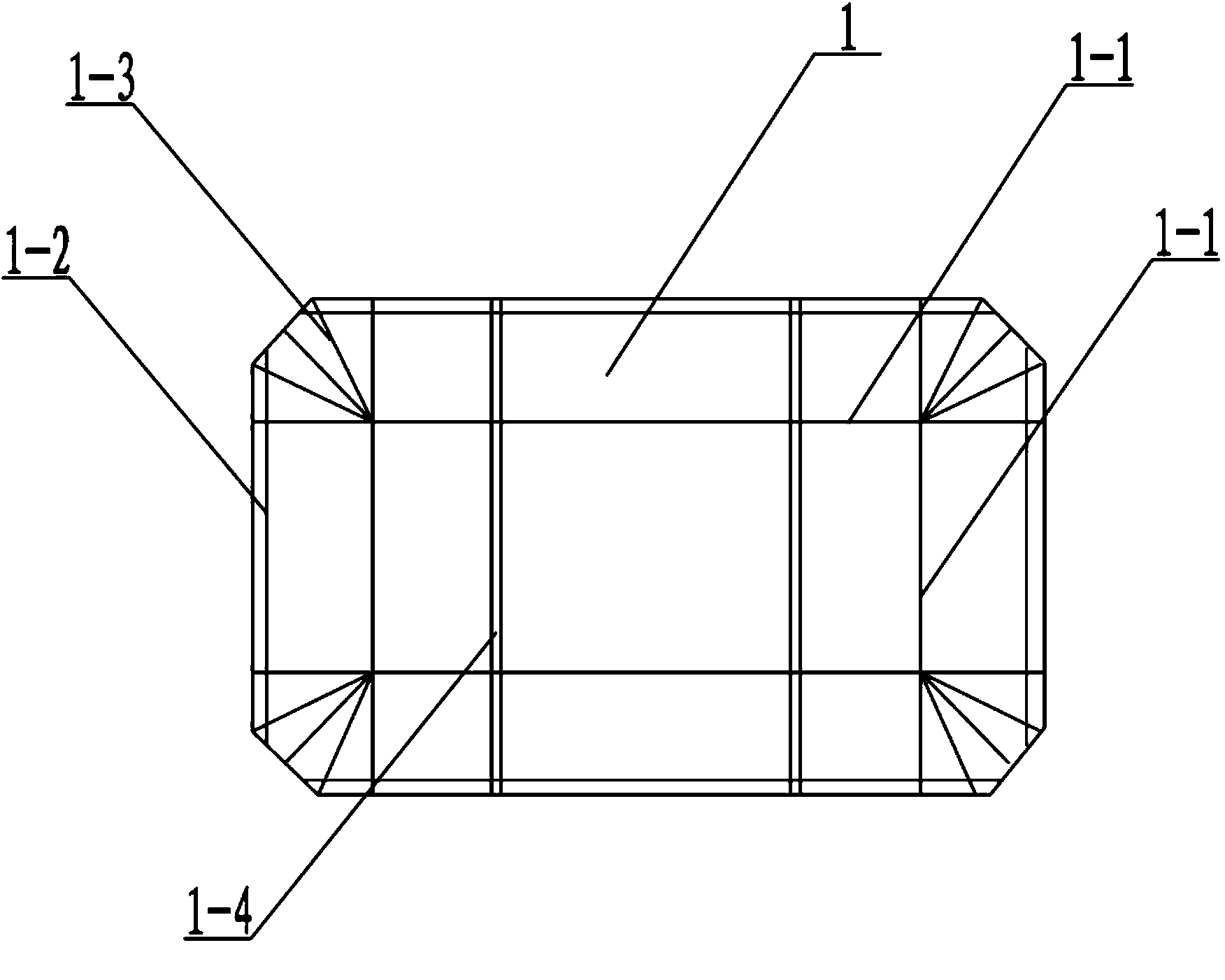

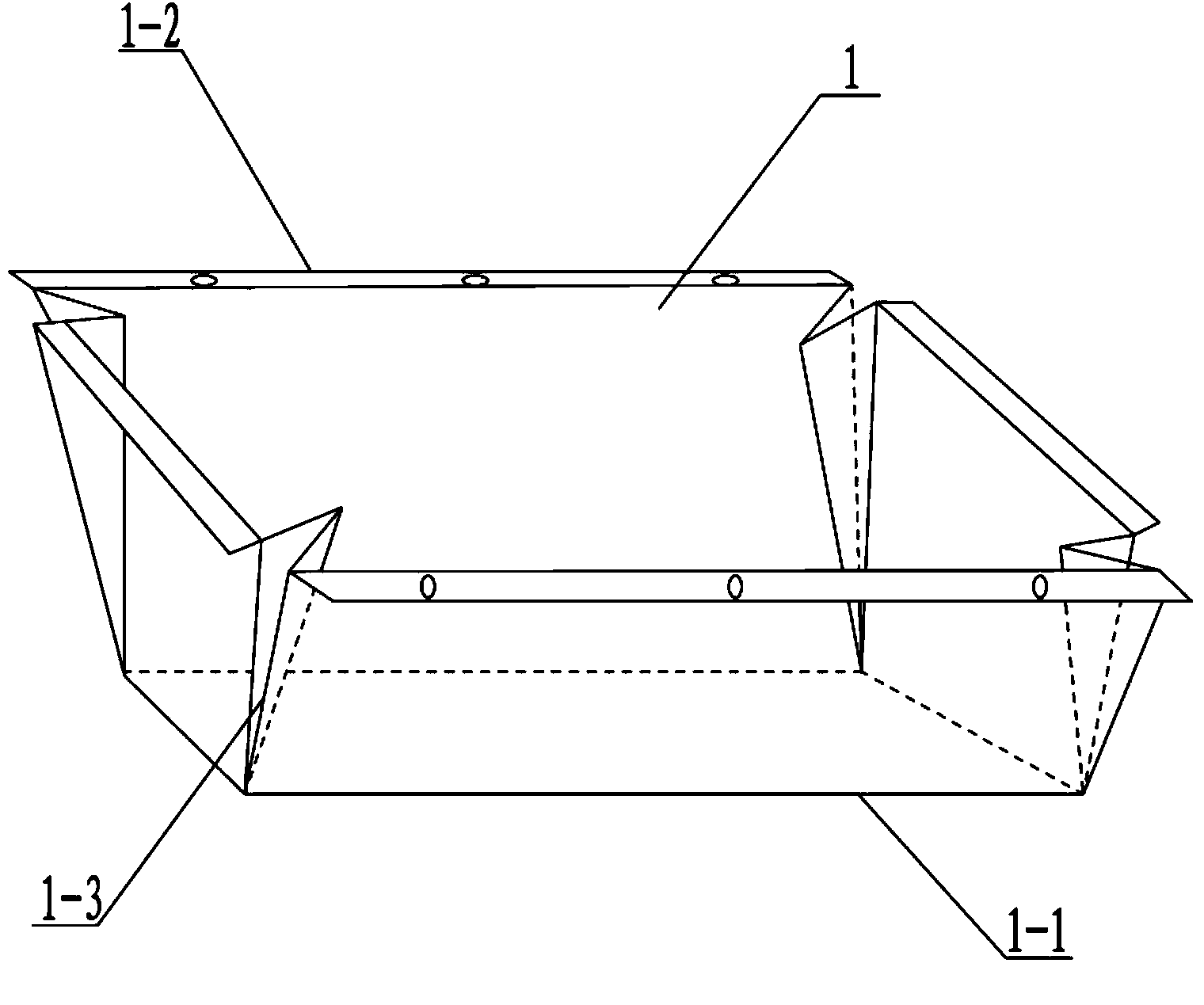

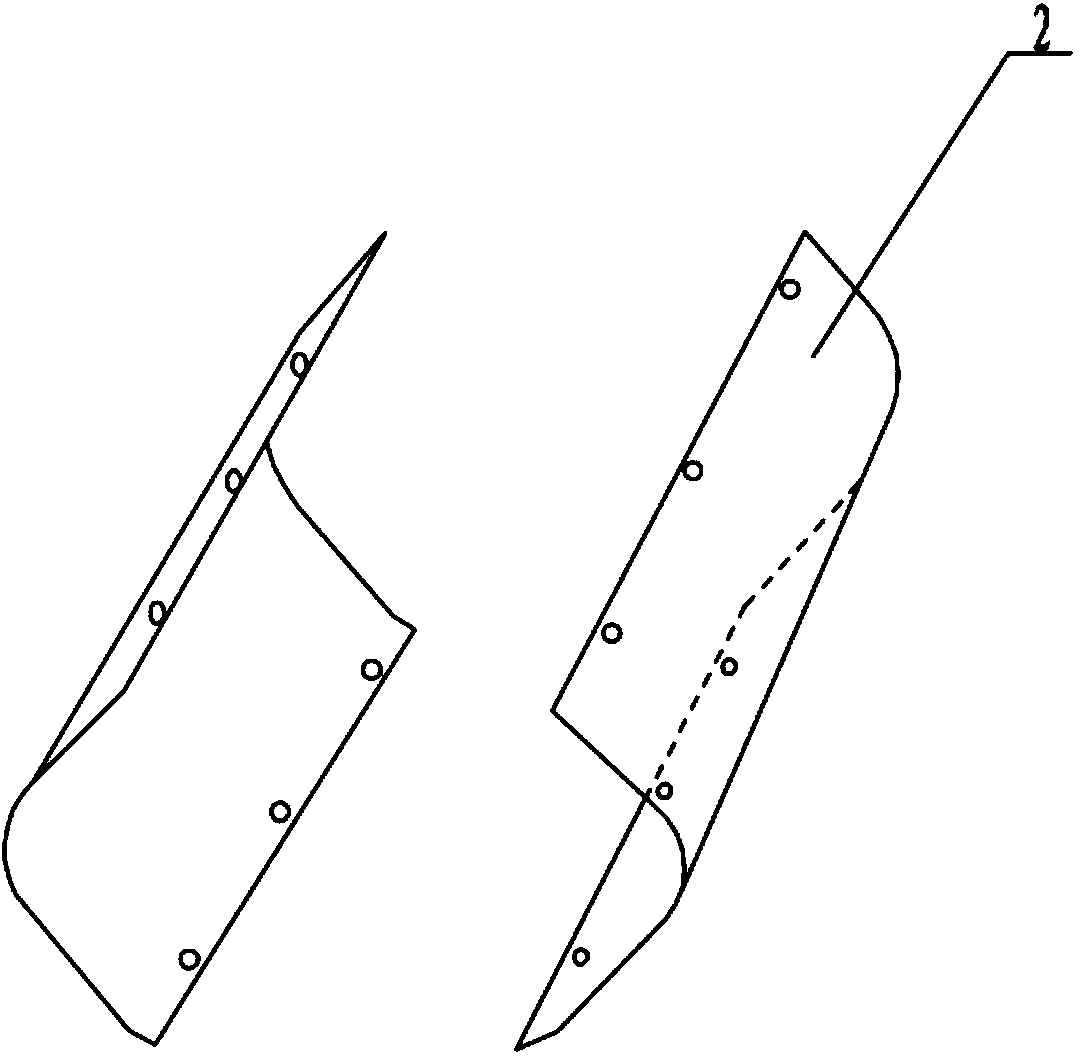

[0022] Specific implementation mode one: combine Figure 1 to Figure 8 This embodiment is described. A hydrofoil folding boat according to this embodiment includes a hull 1 , two hydrofoils 2 , four four-corner connecting plates 3 , and a seat plate 7 . The hull 1 is a rectangular planar thin plate with four corners cut off, and two horizontal and two longitudinal hull folding grooves 1-1 are cut out at selected positions on the thin plate; at selected positions around the edges of the rectangular planar thin plate, a ship edge folding groove 1 is cut out -2; at the intersection point of two horizontal and two longitudinal hull folding grooves 1-1, to the four corners of the rectangular planar thin plate, three radial four-corner folding grooves 1-3 are cut; at the selected position in the middle of the rectangular planar thin plate, Two groups of carrying folding grooves 1-4 are cut horizontally, and each group of carrying folding grooves 1-4 is composed of two parallel foldi...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 , figure 2 , Figure 5 and Figure 6The present embodiment will be described. The material of the rectangular planar thin plate of the present embodiment is polypropylene. Set up in this way, the present embodiment uses a planar sheet for making a folding boat, with a length of 3 meters, a width of 1.8 meters, and a thickness of about 5 millimeters. In the middle of the rectangular flat sheet, at a distance of 450 mm from the edges of the four sides, two horizontal and two vertical hull folding grooves 1-1 are cut, with a groove depth of 2.5 mm; at a distance of 50 mm from the edges of the four sides, the folding grooves 1-2 along the hull are cut. ; At the intersection point of two horizontal and two longitudinal hull folding grooves 1-1, to the four corners of the rectangular plane sheet, three radial folding grooves 1-3 are cut; at the selected position in the middle of the rectangular plane sheet, cut horizo...

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 , figure 2 , Figure 5 and Figure 6 The present embodiment will be described. The thickness of the rectangular planar thin plate of the present embodiment is 4 mm to 8 mm. Such arrangement facilitates processing and folding. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com