Method for lifting extra-large type bow portion total segment

A hoisting method and super-large technology, which are applied in the directions of ship parts, transportation and packaging, ship construction, etc., can solve the problems of unfavorable production safety, heavy weight of the bow section, and cross-type operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] As shown in the figure: a hoisting method for a super-large bow section, including the following assembly steps:

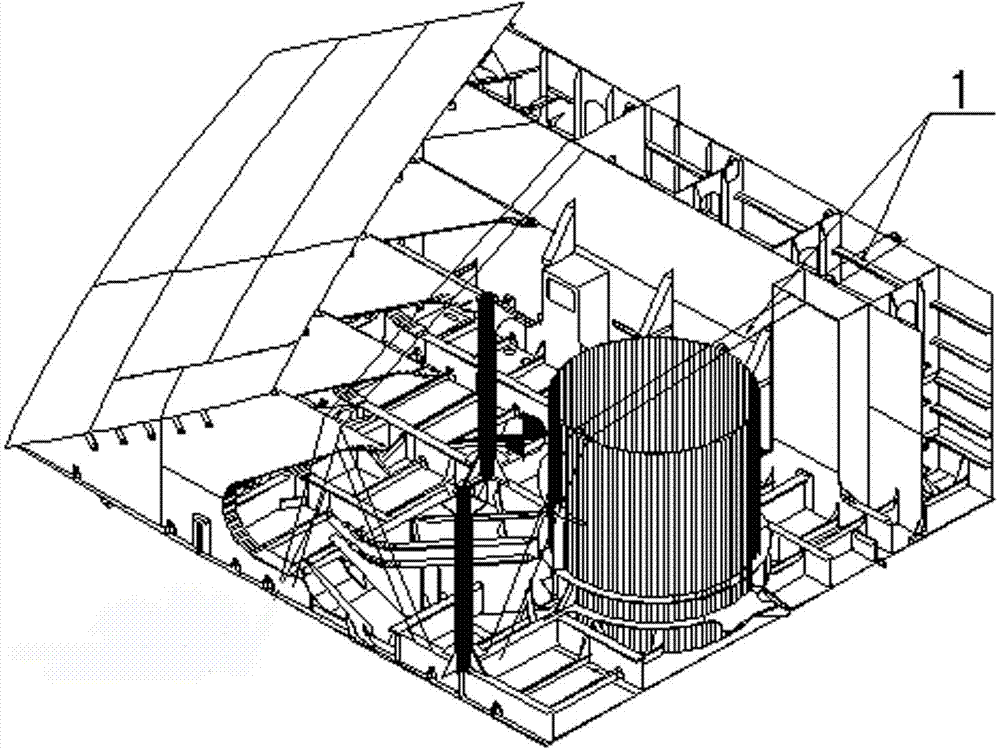

[0020] Reinforcement of each segment: the large opening of the weak gear in each segment of the bow is reinforced with channel steel 1 connection frame structure;

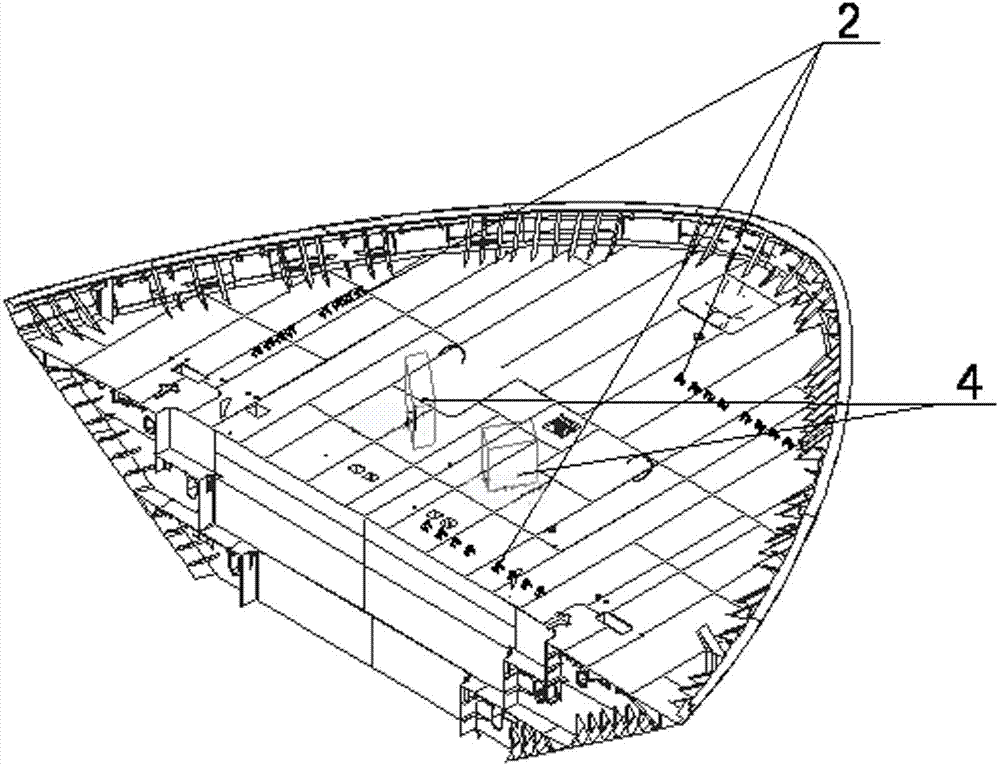

[0021] Segmented hoisting horses: Design hoisting horses 2 for each segment, taking into account the overall section of the bow after assembly of each segment, using each segmented hoisting horse for general segment hoisting;

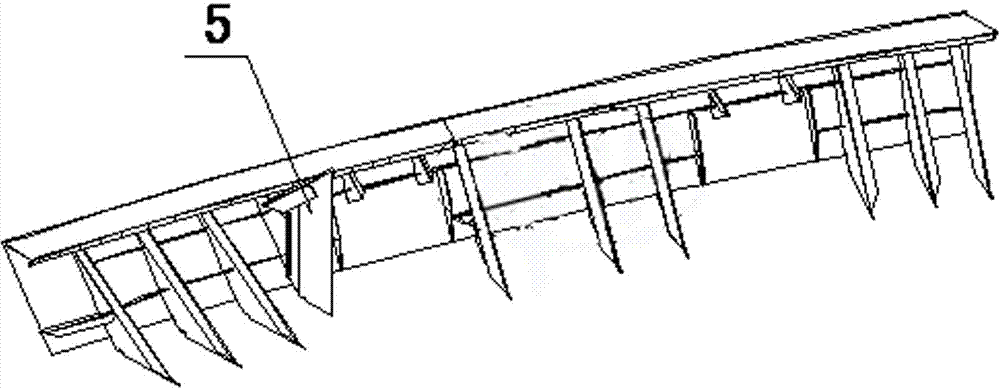

[0022] Anchor winch installation: each section is assembled into the bow general section, and anchor winch 4 and bulwark 5 are installed on the bow deck , The wave wall 3 behind the anchor winch is not installed;

[0023] Hoisting of the bow general section: channel steel is used to connect the strong structure on the longitudinal wall of the bow general section at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com