Equipment utilizing plastic ties to automatically bind wire harnesses

A plastic cable tie and automatic technology, which is applied to the parts of the strapping machine, strapping materials, paper/cardboard containers, etc., can solve the problems of the overall appearance error of the wire harness, loose binding of the cable tie, and high price, etc., to achieve neat specification of the wire harness, The effect of fast forming speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The mechanism of the present invention will be described in further detail below in conjunction with the accompanying drawings.

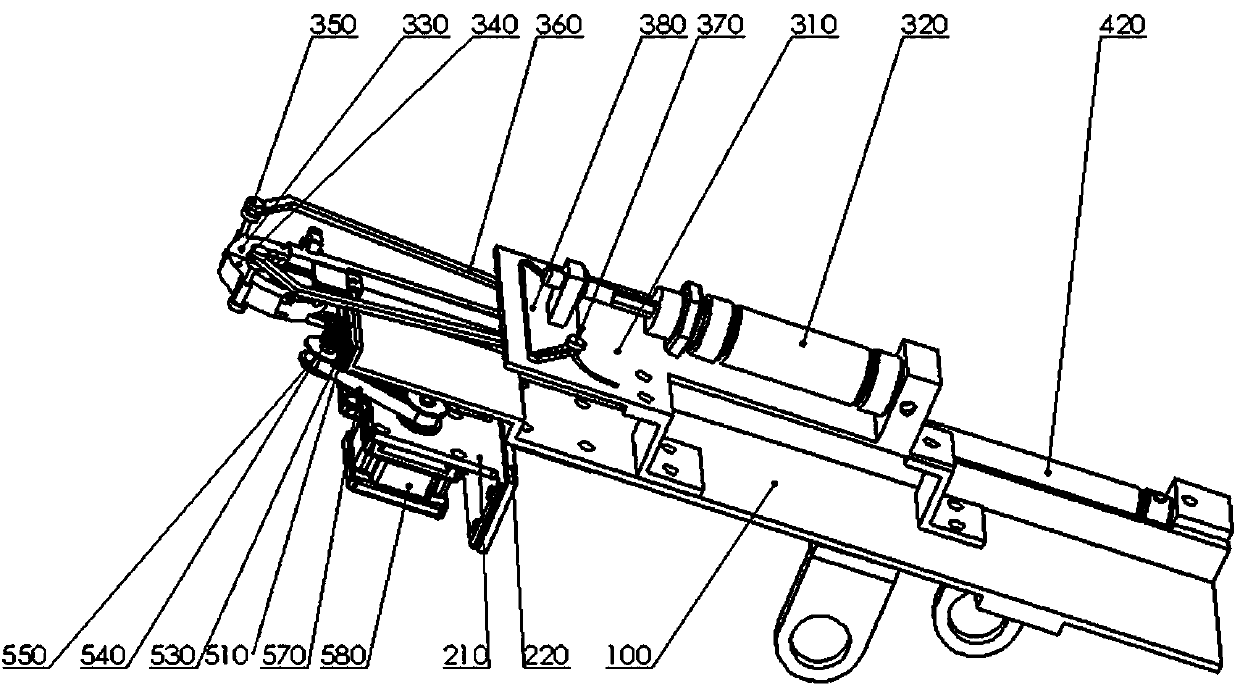

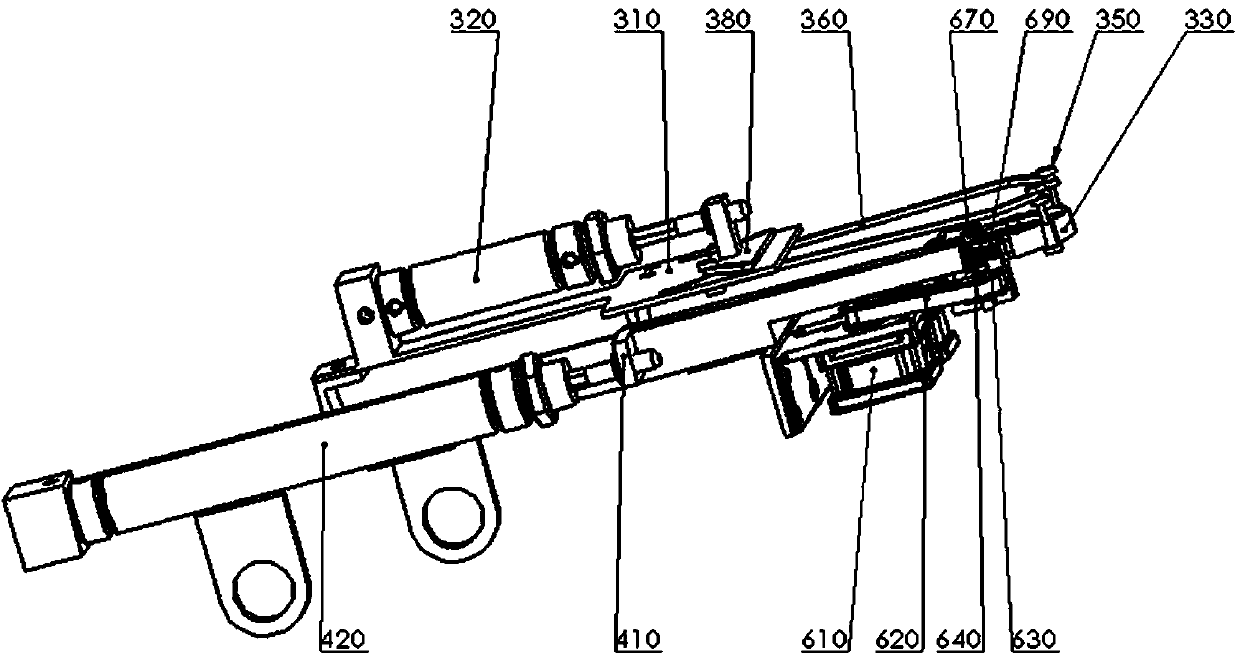

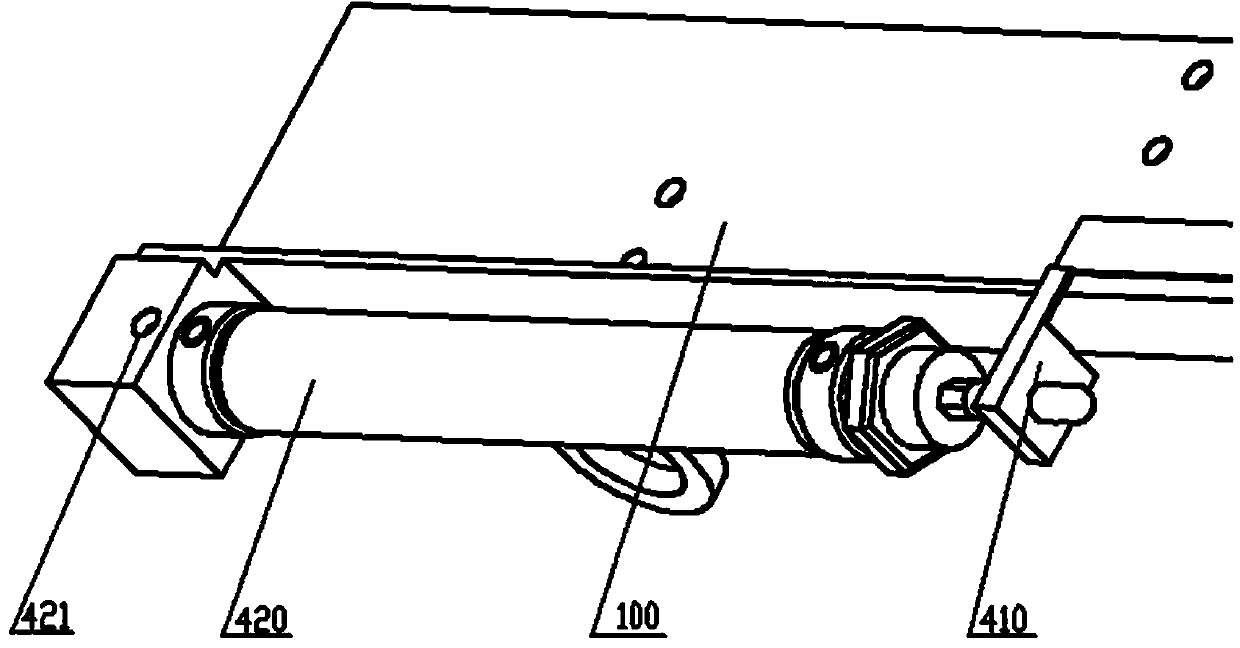

[0028] See figure 1 , figure 2 . An automatic binding device for plastic cable ties, comprising a base 100, a motor fixing mechanism (including 210, 220), a closing control mechanism (including 310, 320, 330, 340, 350, 360, 370, 380), a pushing mechanism (including 410 , 420), boosting mechanism (including 510, 540, 540, 550), tensioning mechanism and shearing mechanism (including 610, 620, 630, 640, 670, 690); the closing control mechanism, pushing mechanism, auxiliary The push mechanism, the tension mechanism, the shear mechanism, and the motor fixing mechanism are all arranged on the base; Figure 10 ) reaches the clamping groove, the clamping groove clamps the tail 830 of the plastic cable tie so that it cannot move, the closing control mechanism organizes the tied objects and places them on the plastic cable tie, and the plastic cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com