screw conveyor

A screw conveyor, conveyor technology, applied in the field of conveyors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

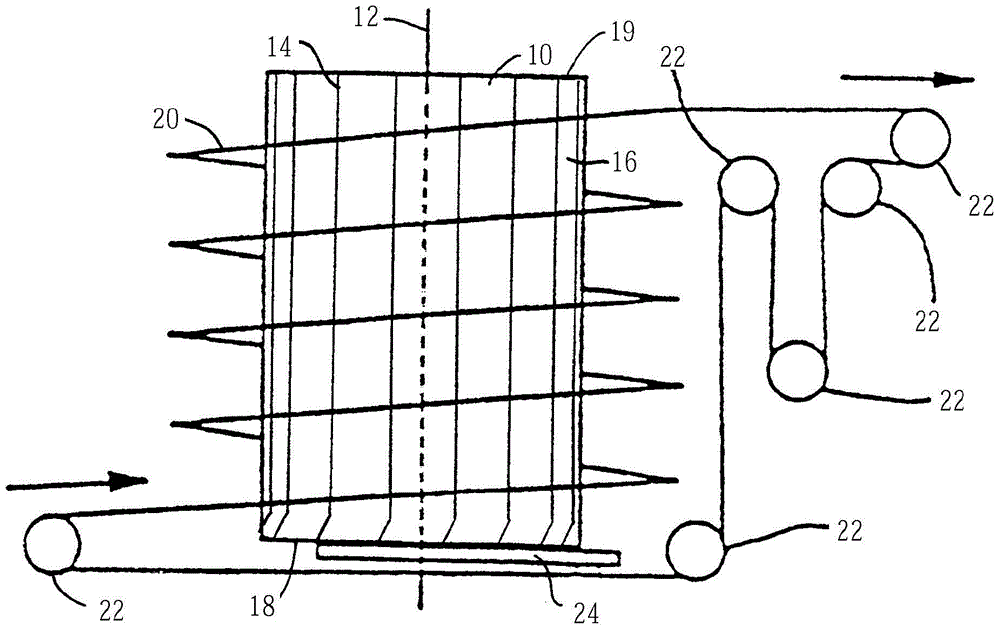

[0072] figure 1 A screw conveyor is schematically shown in . The screw conveyor comprises a drive tower 10 in the form of a cylindrical drum or cage, driven to rotate about a vertical axis 12 . The rotating tower has a plurality of parallel, generally vertical drive members 14 regularly spaced around its perimeter 16 . Each drive member extends in length between the bottom 18 and the top 19 of the tower. The conveyor belt 20 follows a multi-level helical path around the tower. The path is defined by a screw carryway or by a carryway at the bottom and stacker plates mounted on the belt. The inner edge of the belt positively engages the drive members which drive the belt upwards as the tower rotates. The belt travels around different receiving, idle and feeding sprockets 22 , which create a path back from the outlet at the top of the tower to the inlet at the bottom. Tower 10 is mounted at its base to a base 24 and is turned by an electric motor and gears (not shown).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com