Paper folding method of door closing folding

A technology of paper strips and guide blocks, applied in the field of door-closing origami, can solve problems such as low work efficiency and difficult door-folding, and achieve the effects of saving manpower, improving production efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

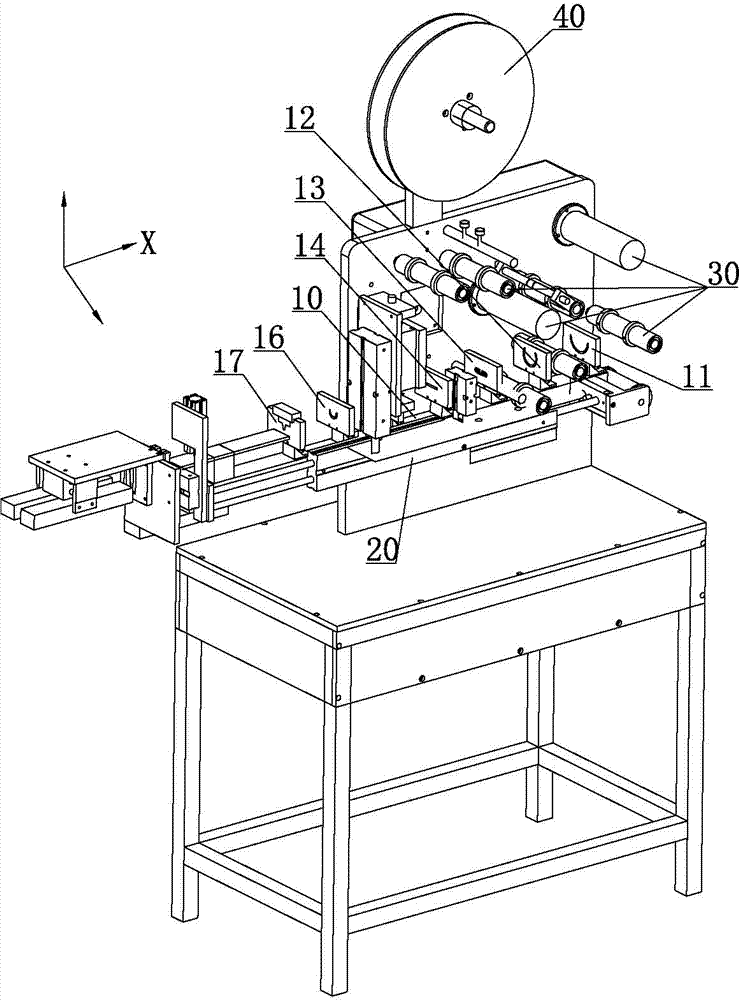

[0031] Such as Figure 1 to Figure 3 As shown, a kind of closed door origami method of the present invention comprises the following process steps:

[0032] (a) Arrange arc-shaped hole guide block 11, U-shaped hole guide block 12, return-shaped hole guide block 13, bar-shaped hole guide block 14, and V-shaped hole guide block 16 on a horizontal guide rail 10 in sequence;

[0033] (b) The beginning of the paper strip passes through the arc-shaped hole guide block 11, the U-shaped hole guide block 12, the return-shaped hole guide block 13, the bar-shaped hole guide block 14, and the V-shaped hole guide block 16;

[0034] (c) Pull the beginning of the paper strip, the paper strip first passes through the arc-shaped hole guide block 11, and the arc-shaped hole guide block 11 makes the paper strip bend into an arc; then the paper strip passes through the U-shaped hole guide block 12, and the U-shaped hole guides the Block 12 makes paper strip be bent into U shape; Then paper strip...

Embodiment 2

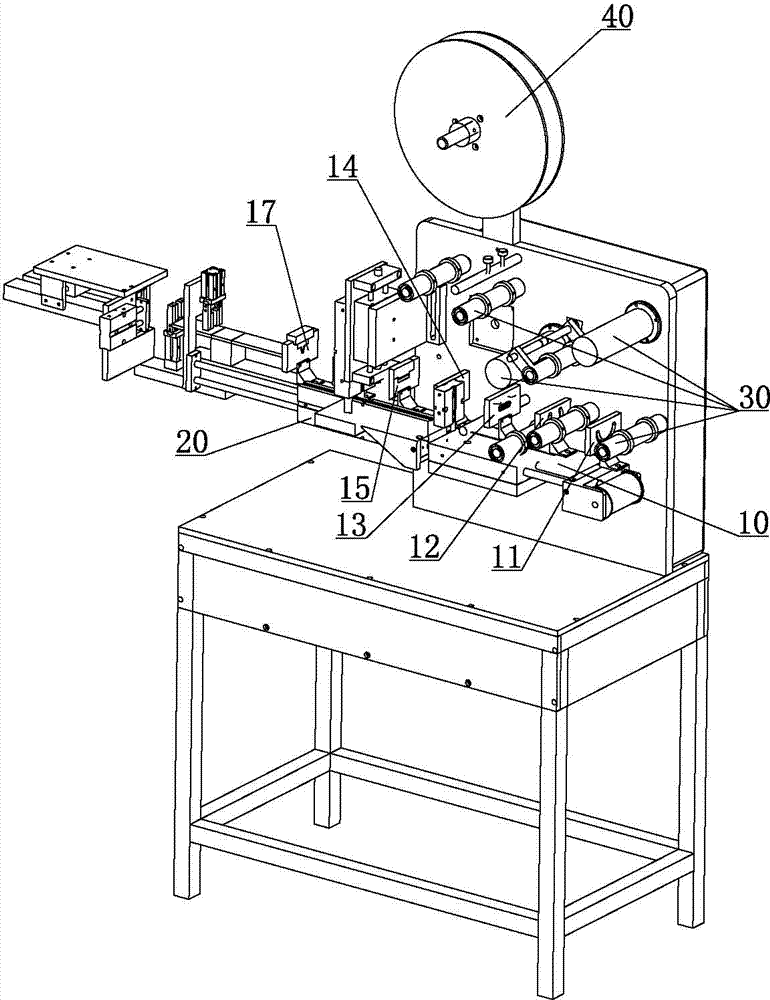

[0042] Such as Figure 1 to Figure 3 As shown, in this embodiment, a concave groove guide block 15 and a "︸" shaped groove guide block 17 are added to the horizontal guide rail 10 in the step (a), and the concave groove guide block 15 is located before the strip hole guide block 14 , After the V-shaped hole guide block 16, the "︸" groove guide block 17 is located behind the V-shaped hole guide block 16;

[0043] Step (b) specifically, the beginning of the paper strip passes through the arc-shaped hole guide block 11, the U-shaped hole guide block 12, the return-shaped hole guide block 13, the bar-shaped hole guide block 14, the concave groove guide block 15, V-shaped hole guide block 16, "︸" groove guide block 17;

[0044] Step (c) is specifically, pulling the beginning of the paper strip, the paper strip first passes through the arc-shaped hole guide block 11, and the arc-shaped hole guide block 11 makes the paper strip bend into an arc; then the paper strip passes through t...

Embodiment 3

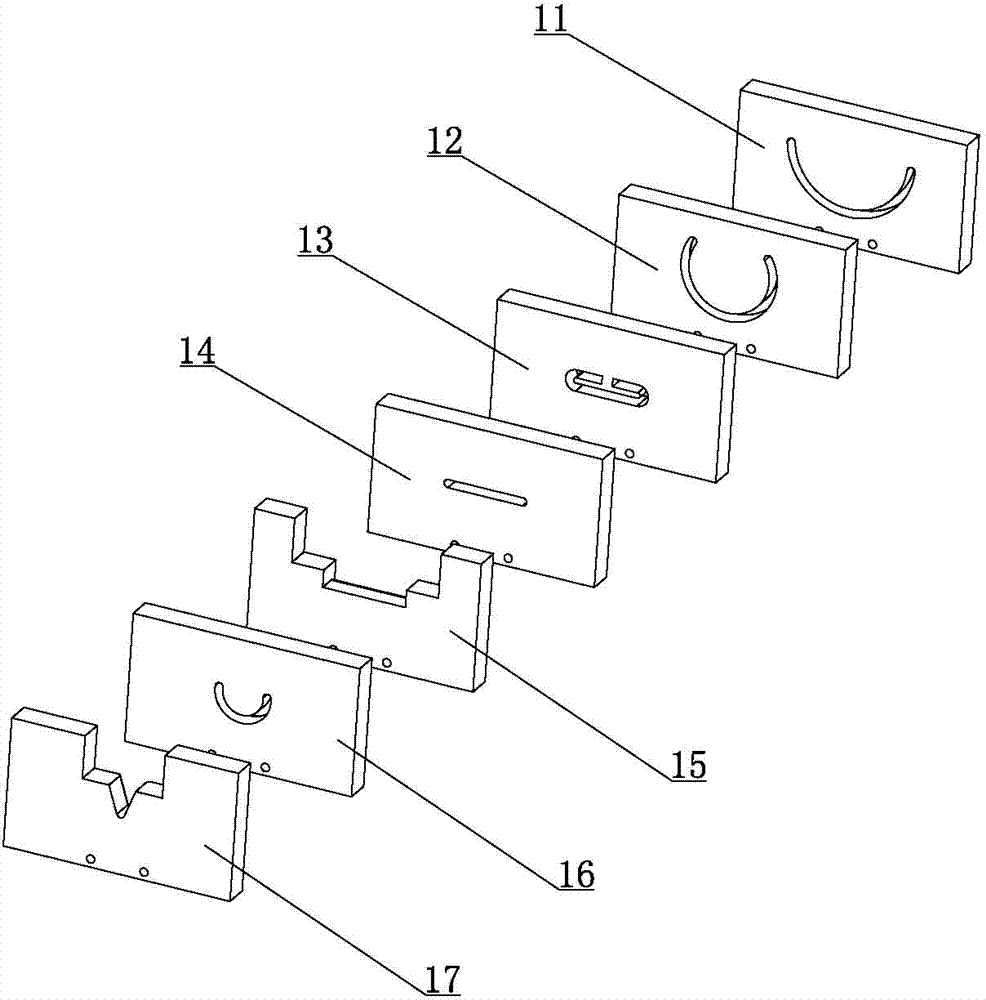

[0048] The difference between this embodiment and the second embodiment is that a convex block 151 that cooperates with the concave groove of the concave groove guide block 15 is provided above the concave groove guide block 15; The top of the groove guide block 17 is provided with a "︸" shape block 171 that cooperates with the "︸" shape groove of the "︸" shape groove guide block 17, see Figure 4 and Figure 5 .

[0049] In order to ensure that when the paper strip passes through the concave groove of the concave groove guide block 15, to prevent the paper strip from being stretched and broken or too loose to affect the origami effect due to the excessive speed of the telescopic cylinder 20; the designed concave groove cooperates with the convex Block 151 can also ensure convenient installation and replacement of paper strips, adjust the origami effect of paper strips, and adjust whether it needs to be folded tighter or looser according to the requirements of origami; wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com