Railway vehicle jacking tool

A technology for railway vehicles and cranes, which is applied in the direction of lifting devices, etc., can solve the problems of limiting the use range of cranes, inconvenient vehicle maintenance work, and increasing maintenance costs, so as to improve safety and reliability, improve operability, Functionally reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

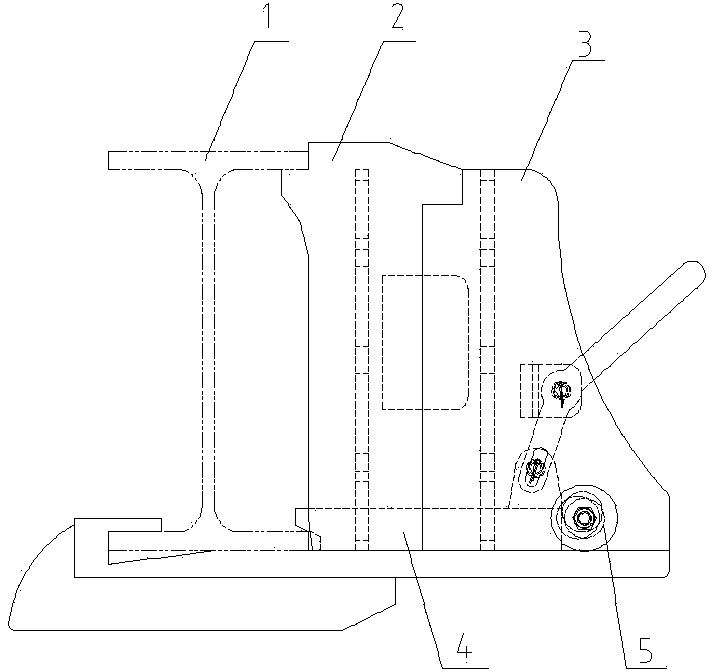

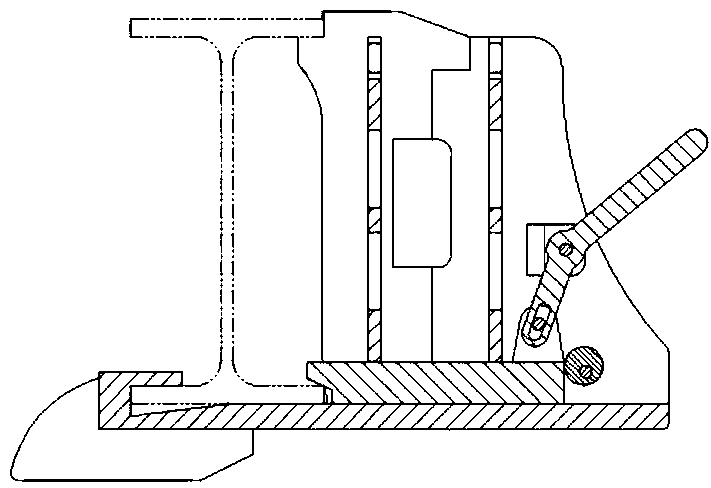

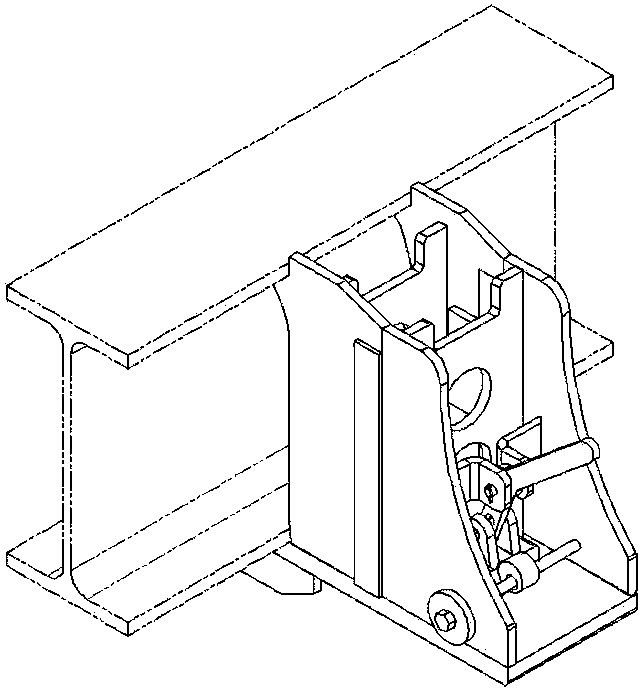

[0032] Such as figure 1 It is a structural diagram of the frame truck tooling, including a base mechanism 3, an adjustment mechanism 2, a clamping mechanism 4, and a camshaft mechanism 5; the base mechanism 3 includes a base bottom plate 7 and two parallel and perpendicular to the base bottom plate 7. The two base side panels 10; the base base plate 7 is matched with the vehicle longitudinal beam; the clamping mechanism includes a handle and a handle base plate connected together; the handle base plate 15 is located between the two base side plates and can be positioned along the base base plate 7 slide back and forth, the handle 16 is fixed on the side plate 10 of the base through a pin shaft, and by adjusting the handle 16, the bottom plate of the dial is slid back and forth along the bottom plate of the base; between the base mechanism 3 and the clamping structure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com