Novel electrostatic spinning machine injection system

A technology of electrospinning machine and jetting system, applied in the directions of electrospinning, textile and papermaking, filament/thread forming, etc. and other problems, to achieve the effect of low experimental cost, beneficial to scientific layout, adjustable injection position and angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

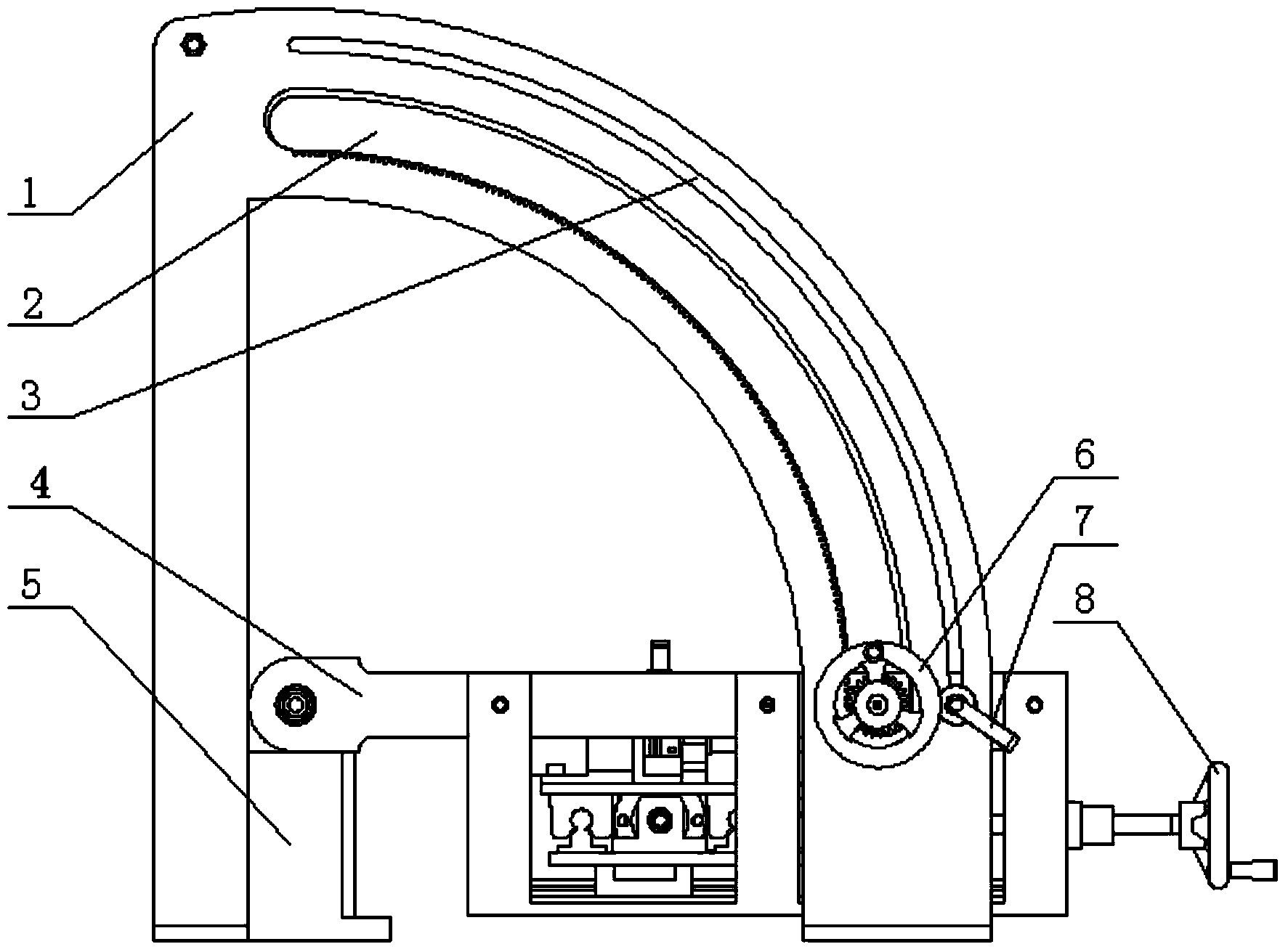

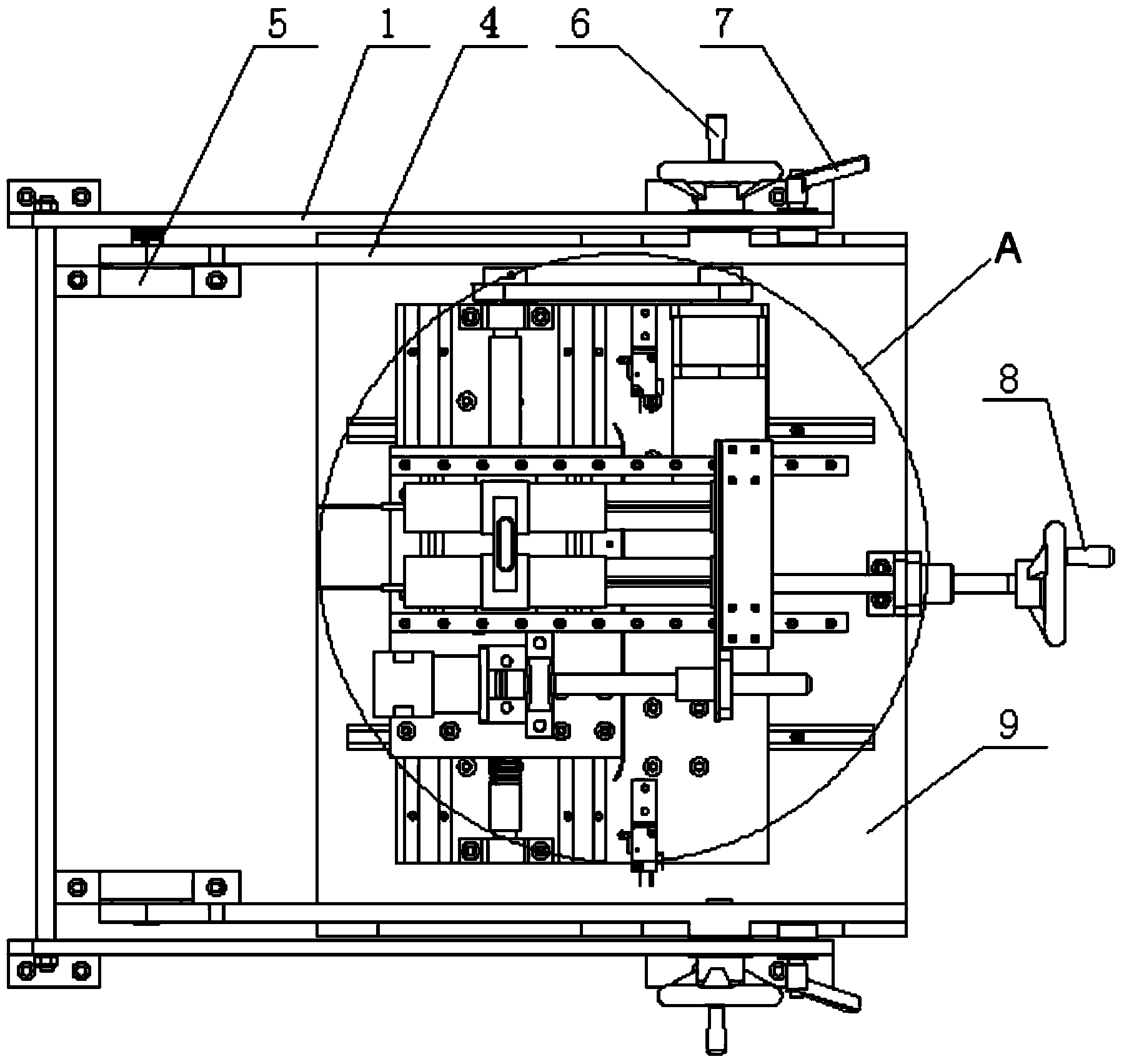

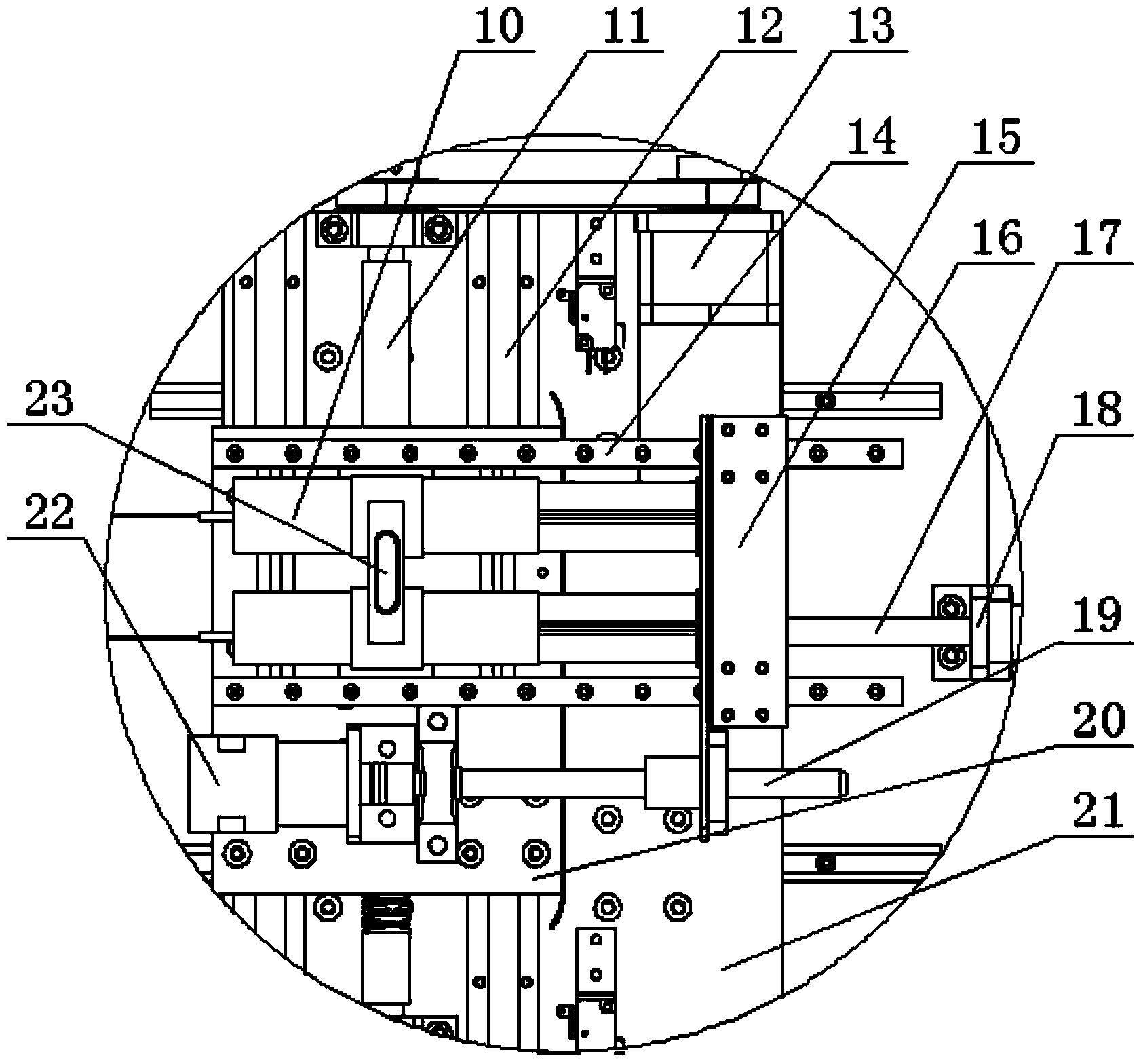

[0026] A new type of electrospinning machine jet system, including jet cylinder 10, its innovation is: also includes a space angle adjustment mechanism and a horizontal direction adjustment mechanism, the space angle adjustment mechanism is composed of a mounting frame 5, an adjustment bracket 4, The adjusting stand 1 and the angle adjusting handwheel 6 are composed of an adjusting bracket which is rotatably installed on the mounting frame, and an adjusting stand connected by a connecting beam 24 is installed symmetrically on both sides of the adjusting bracket. An arc-shaped adjusting hole 2 is made on the body, and adjusting teeth are made in the adjusting hole. An adjusting gear meshing with the adjusting teeth is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com