Dense ball type rotating and reciprocating two-degree-of-freedom rolling shaft system

A dense bead type, degree of freedom technology, applied in the mechanical field, can solve the problems of poor bearing capacity, low transmission efficiency and low reliability of single-layer sliding support shafting, and achieve simple and reliable structure, high transmission efficiency and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

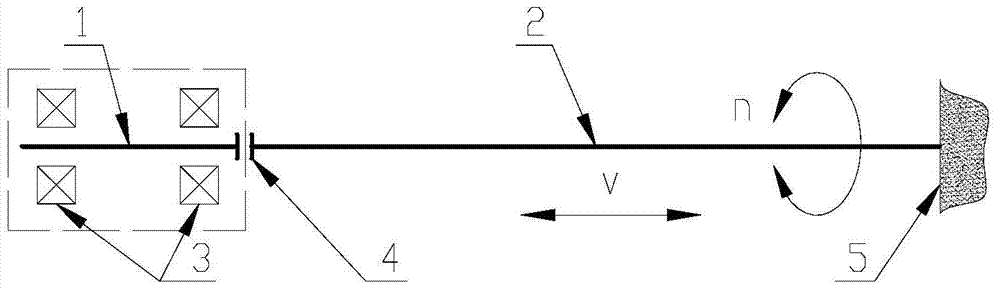

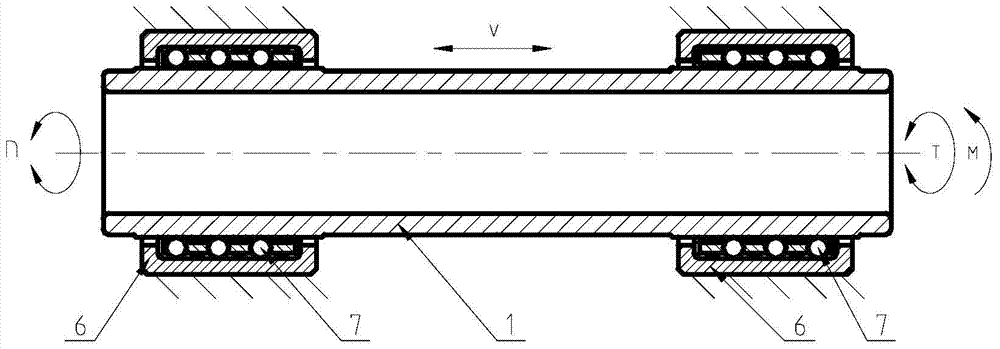

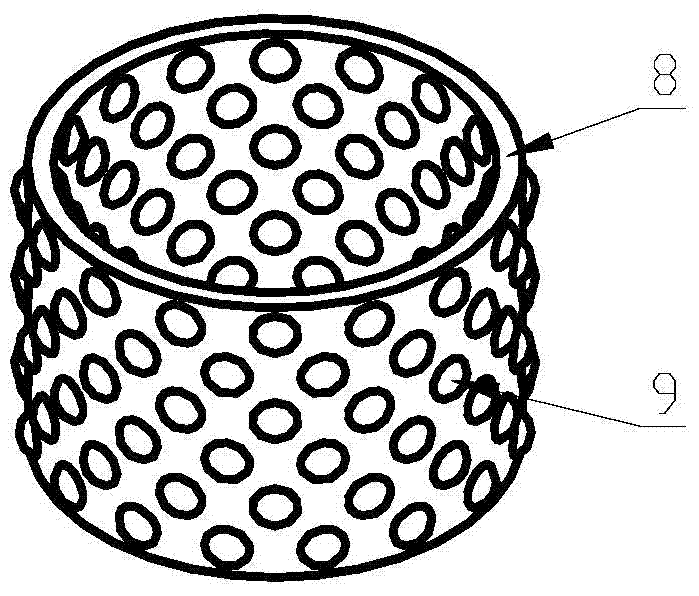

[0029] Such as figure 2 As shown, the dense ball type rotary and reciprocating double degree of freedom rolling shaft system of the present invention includes a transmission main shaft 1 , two bearing casings 6 and two dense ball type bearings 7 .

[0030] The transmission spindle 1 is made of 9Cr18 material, which is a common material for aerospace bearings and has good rust resistance. The end of the transmission spindle 1 is connected to the drilling tool 2. When drilling and sampling, the rotation and impact driving power will be transmitted to the drilling tool 2 through the transmission spindle 1. At the same time, the torque and bending moment generated by the drilling tool 2 will also be transmitted back to the drilling tool 2. On the transmission main shaft 1, it is borne by the rolling shaft system. Both ends of the drive shaft 1 are jointly supported by two dense ball bearings 7 , and a bearing sleeve 6 is arranged on the outer side of each dense ball bearing 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com