Superheating boiler superheating steam desalting device for oil field steam injection and utilization method thereof

A superheated boiler and superheated steam technology, applied in steam superheating, steam generation, earthwork drilling and mining, etc., can solve the problem of no salt reduction, etc., and achieve the effect of reasonable structure, compact structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

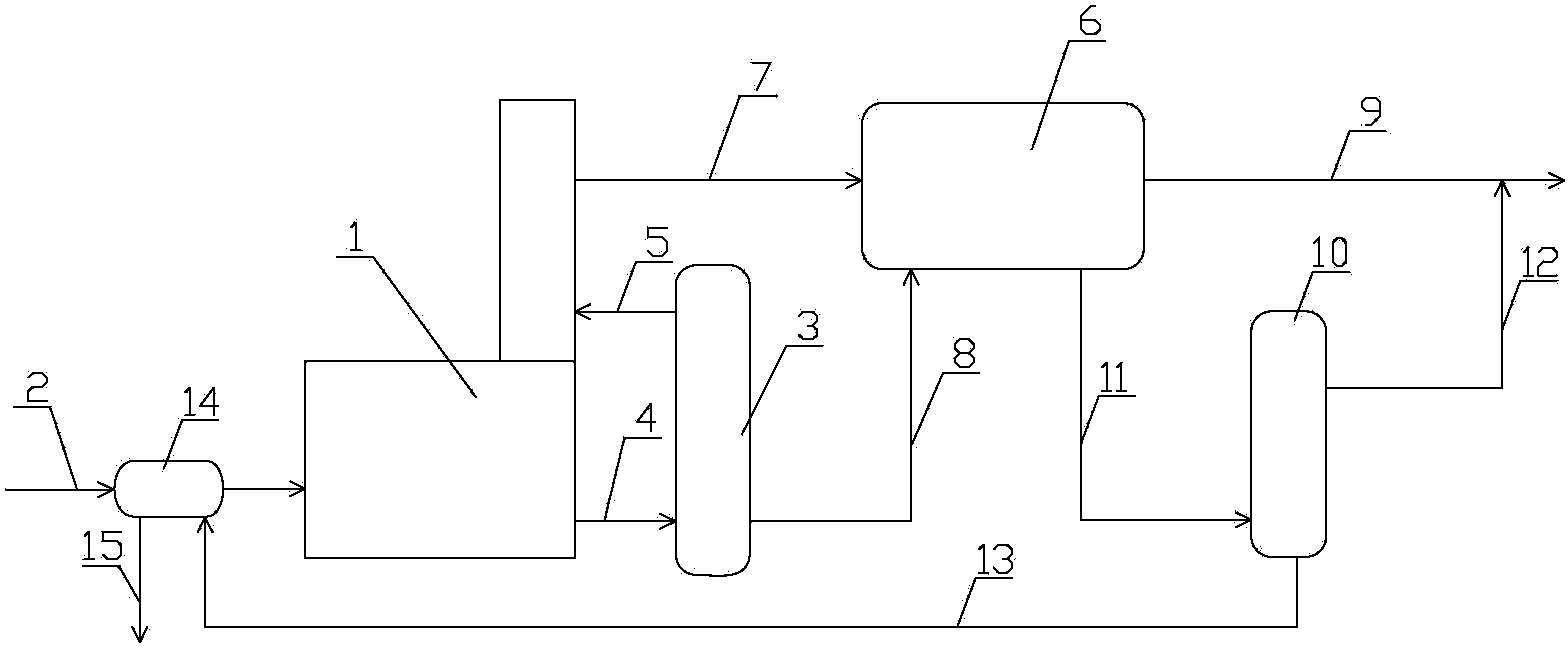

[0014] Embodiment 1, as attached figure 1 As shown, the superheated steam desalination device for steam injection in the oil field includes a superheated boiler 1, a primary steam-water separator 3, a heat exchanger 6, and a secondary steam-water separator 10; the water inlet of the superheated boiler 1 is fixedly installed with softened water The first wet saturated steam pipeline 4 is fixedly installed between the water supply pipeline 2, the water outlet of the radiant section of the superheating boiler 1 and the inlet of the primary steam-water separator 3, the gas outlet of the primary steam-water separator 3 and the superheating section of the superheating boiler 1 The first dry steam pipeline 5 is fixedly installed between the steam inlet, the superheated steam pipeline 7 is fixedly installed between the steam outlet of the superheating section of the superheating boiler 1 and the tube side inlet of the heat exchanger 6, and the liquid outlet of the primary steam-wate...

Embodiment 2

[0015] Embodiment 2, as preferred embodiment 1, as attached figure 1 As shown, a softened water heat exchanger 14 is fixedly installed on the softened water supply pipeline 2, the softened water supply pipeline 2 communicates with the shell side of the softened water heat exchanger 14, and the other end of the concentrated brine pipeline 13 exchanges heat with the softened water The tube side inlets of the device 14 are fixedly installed together, and the tube side outlet of the demineralized water heat exchanger 14 is fixedly installed with a drainage pipeline 15 . The concentrated brine coming out of the secondary steam-water separator 10 has a certain amount of heat. After the heat is exchanged with the demineralized water for heat recovery, it is recycled or crystallized and solidified to further achieve the purpose of saving energy and reducing consumption.

Embodiment 3

[0016] Embodiment 3, the use method of the superheated steam desalination device of the superheated boiler for steam injection in the oil field is carried out according to the following steps: the first step, the wet saturated steam coming out of the radiant section of the superheated boiler first enters a first wet saturated steam pipeline through the first wet saturated steam pipeline The first-stage steam-water separator is used for steam-water separation, and dry steam and saturated water are obtained after being treated by the first-stage steam-water separator; in the second step, the saturated water from the first-stage steam-water separator enters the shell side of the heat exchanger through the saturated water pipeline, and is fed by The dry steam from the primary steam-water separator enters the superheating section of the superheated boiler through the first dry steam pipeline to form superheated steam, and the superheated steam enters the tube side of the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com