Enameled wire varnish stripping device

An enameled wire and paint stripping technology, which is applied in transformer/coil connectors, circuit/collector parts, electrical components, etc., can solve the problems of low paint stripping efficiency, failure to adjust the length of paint stripping, and improvement of paint stripping rate, etc. To achieve the effect of perfect function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

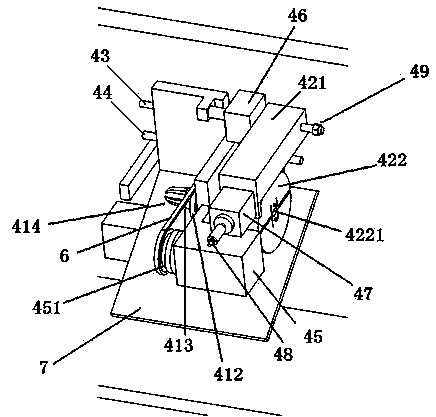

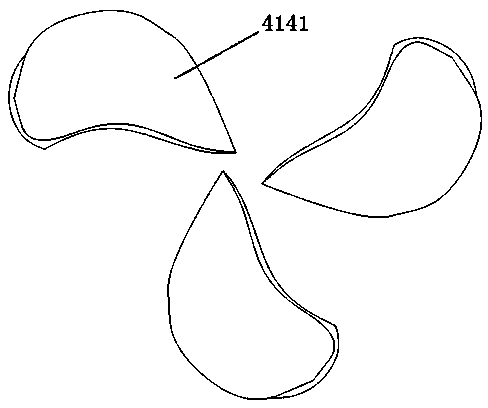

[0026] figure 1 Shown is a three-dimensional structural view of the enameled wire stripping device of Embodiment 1. The enameled wire stripping device of the present invention includes a support 2, a transmission assembly 3, a paint stripping assembly 4, a power assembly and a bracket 5, the support 2 is vertically fixed on the workbench 1, the transmission assembly 3, the paint stripping assembly 4 and the power assembly are installed on the support 2, wherein the paint stripping assembly 4 is arranged on the bracket 5 and fixed on the support 2; the power assembly includes a motor, a first cylinder 46 and the second cylinder 47 . The device uses the conveying component 3 to transmit the enameled wire to the paint stripping component 4, and the paint stripping component 4 strips the enameled wire.

[0027]The transmission assembly 3 includes a fixed shaft 31 , a transmission gear 32 , a first transmission support mechanism 33 and a second transmission support mechanism 34 ....

Embodiment 2

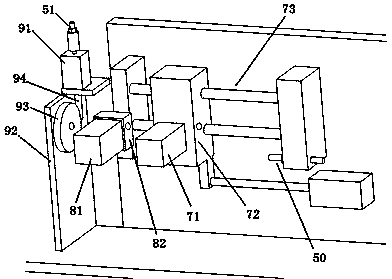

[0034] Figure 4 Shown is the three-dimensional structural view of the enameled wire stripping device of the second embodiment. The enameled wire stripping device of the present invention comprises a support 2, a transmission assembly 3, a paint stripping assembly 4, a cutting assembly, a power assembly and a bracket 5, the support 2 is vertically fixed on the workbench 1, the transmission assembly 3, the stripping assembly The paint assembly 4 , the cutting assembly and the power assembly are all mounted on the bracket 2 , wherein the paint stripping assembly 4 is arranged on the bracket 5 and fixed on the bracket 2 . The device utilizes the conveying assembly 3 to convey the enameled wire to the paint stripping assembly 4, the paint stripping assembly 4 strips the enameled wire, and the cutting assembly is used to cut the enameled wire into multiple enameled wires of equal length.

Embodiment 2

[0035] The enameled wire paint stripping device in embodiment two has the same support 2, transmission assembly 3, paint stripping assembly 4, cutting assembly, power assembly and bracket 5 with the enameled wire paint stripping device in embodiment one, the difference is that in the implementation On the basis of the enameled wire stripping device in Example 1, the cutting function and the power part to realize this function are added. For example, 4 and 5, the cutting assembly includes a delivery part 7, a fixing part 8 and a cutting part 9, and the cutting part 9, the fixing part 8, the delivery part 7, the paint stripping assembly 4 and the The transmission components 3 are installed side by side on the support 2 in sequence. The power assembly also includes a third cylinder 71, a fourth cylinder 81 and a fifth cylinder 91, respectively controlling the conveying part 7 to convey the enameled wire, controlling the fixing part 8 to stabilize the enameled wire and controlling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com