A valve-level control method for flexible direct current transmission system

A power transmission system, flexible DC technology, applied in the direction of DC network circuit devices, AC network circuits, electrical components, etc., can solve problems such as processing a large amount of data, and achieve the effects of reducing losses, reducing time occupied, and low harmonic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

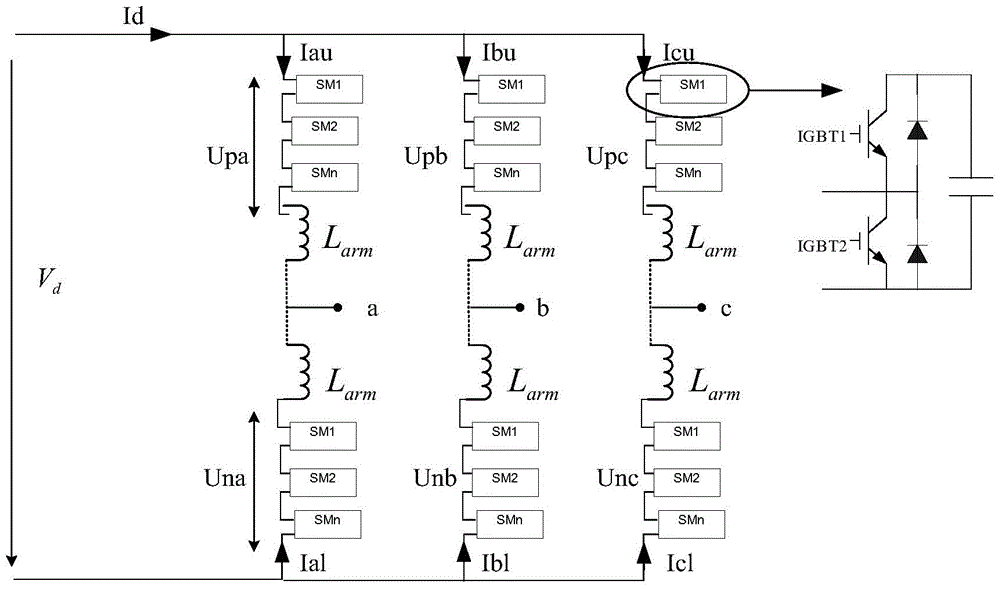

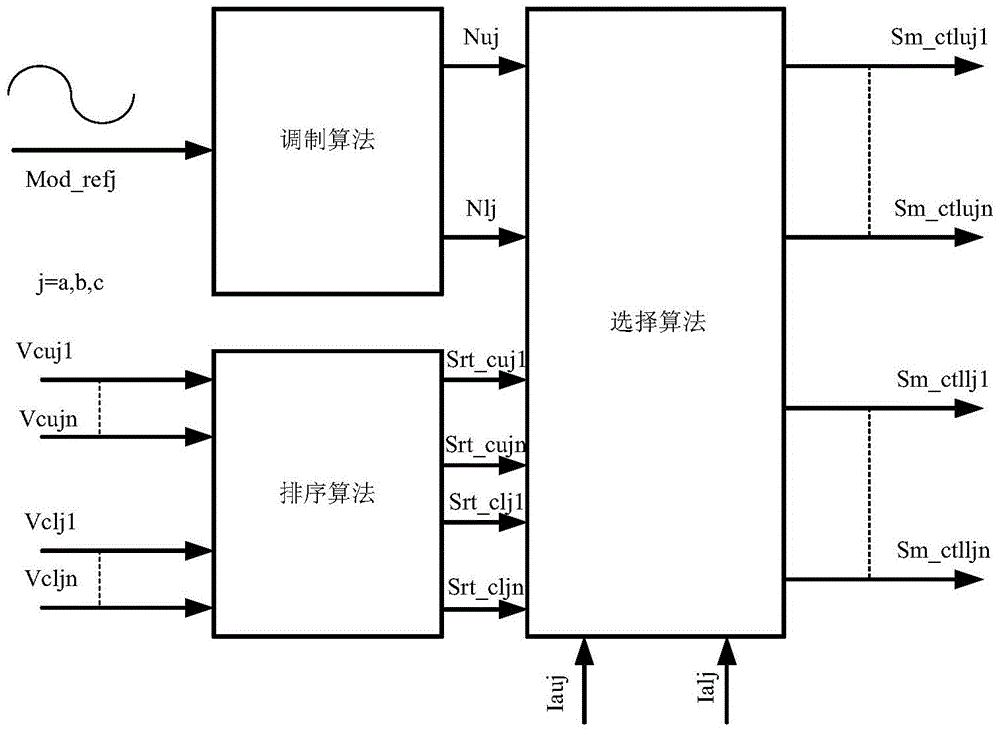

[0028] The flexible direct current transmission system of the present invention is composed of three-phase six bridge arms, and each bridge arm is composed of coupled or uncoupled inductors and N identical sub-modules cascaded. Each sub-module consists of two IGBTs, two reverse diodes and a DC capacitor, the structure is as follows figure 1 As shown, the DC current and the current flow direction of the upper and lower arms are as follows figure 1 As shown, the valve-level control method of the flexible DC transmission system is composed of modulation algorithm, sorting algorithm and selection algorithm. The specific principle is shown in figure 2 , the valve-level control method of the flexible direct current transmission system includes the following steps:

[0029] 1 According to the signal issued by the extreme control of the valve-lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com