A camera module signal wiring method

A camera module and data signal line technology, which is applied in image communication, TV, color TV, etc., can solve the problems of large difference in signal pair wiring length, camera module signal distortion, limited space area, etc., and achieve transmission rate Consistent, good anti-interference, good effect of differential impedance control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

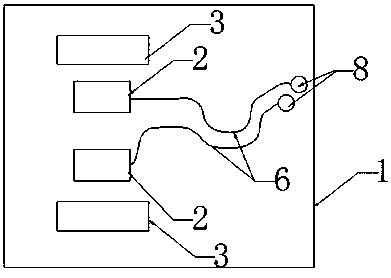

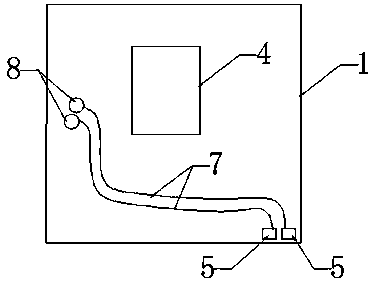

[0029] Along the data signal line, the MIPI first performs detour parallel routing on the front of a PCB board of the substrate body, and then goes around to the back of the PCB board through the through hole, and continues to detour parallel routing along the data signal line, and finally , the total trace length of the signal pair is matched.

Embodiment 2

[0031] Along the data signal line, the MIPI pair first detours parallel wiring on the front of one PCB board of the substrate body, and then goes around to the front of another adjacent PCB board through the through hole, and continues to detour along the data signal line in parallel. trace, and eventually, the total trace length for that signal pair is matched.

[0032] Under the condition of relatively limited design space, the present invention adopts the above-mentioned detour parallel wiring method on a multi-layer substrate with a main body size of 8.5×8.5mm, 7.5×7.5mm, or 6.5mm, which changes the previous MIPI signal Always maintain a straight line and parallel way when aligning the traces, and finally achieve the same width and spacing of the MIPI signal pair traces, and match the length of the traces to make the transmission rate consistent. (refer to image 3 , 4 , 5)

[0033] This differential signal (differential signal) pair trace length matching routing method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com