drive train

A technology of drive system and drive shaft, applied in the field of drive system, can solve the problems of heavy, high cost, limited power, etc., and achieve the effect of compact moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

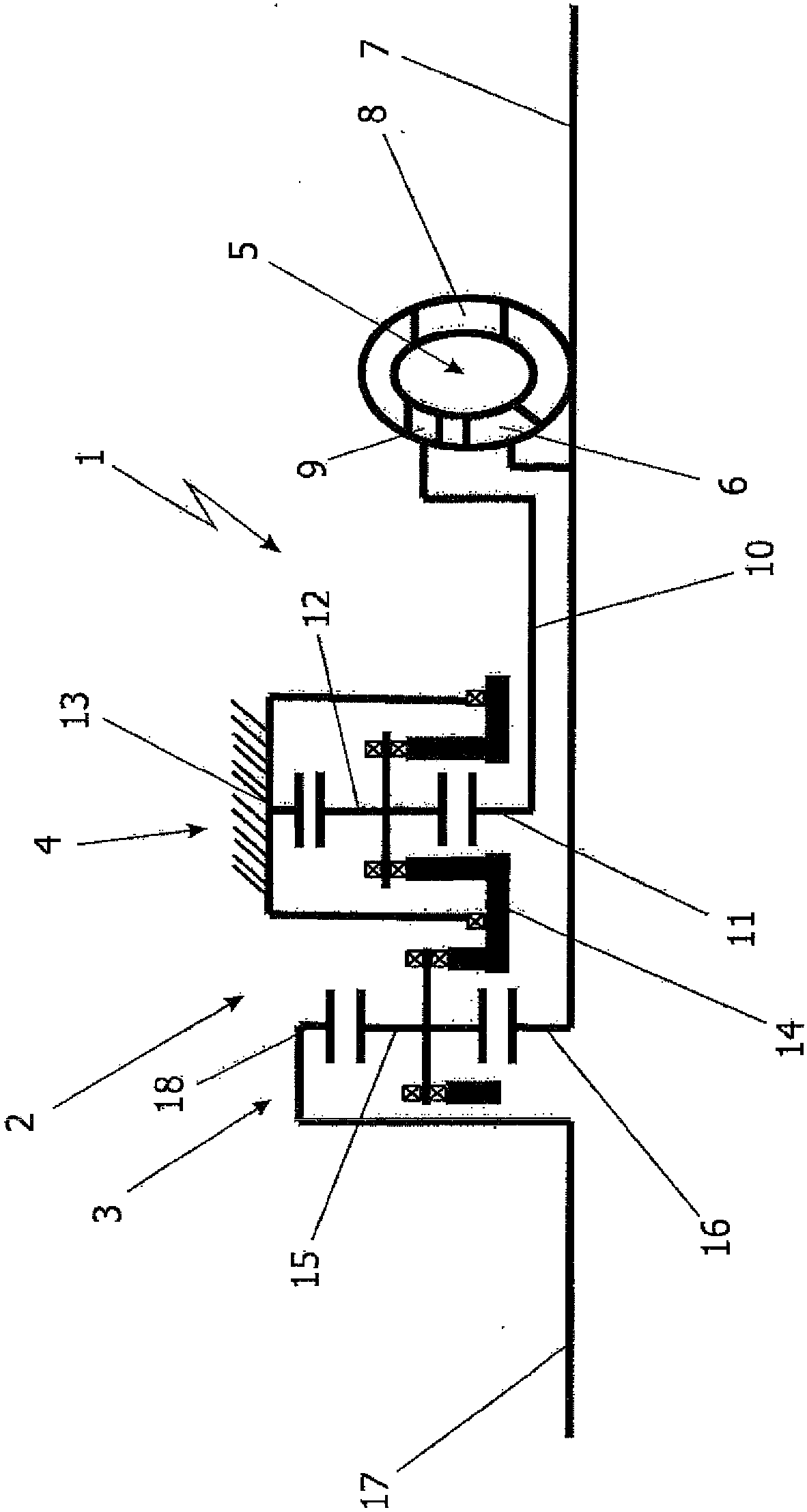

[0015] In the single figure shown, the upper half of the essentially rotationally symmetrical drive train 1 is highly schematically illustrated. This upper part is to be understood as a principle presentation for explaining the idea according to the invention. Here it is a possible embodiment in which an upstream and / or downstream mounted transmission is omitted. The drive train 1 shown basically comprises a power-split transmission 2 with a first planetary transmission 3 as a superposition transmission. Furthermore, the second planetary gear 4 configured as a planetary gear is part of the power split gear 2 of the drive train 1 according to the invention.

[0016] Another important component of the drive train 1 according to the invention is the hydrodynamic component 5 , which can form, for example, a converter, a Trilok converter or possibly also a hydrodynamic clutch. In the exemplary embodiment shown here, the hydrodynamic component 5 is designed as a hydrodynamic conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com