Fluid fuel burning device

A fluid fuel and combustion device technology, applied in the direction of gas fuel burners, burners, combustion chambers, etc., can solve a large number of soot NOx particles and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

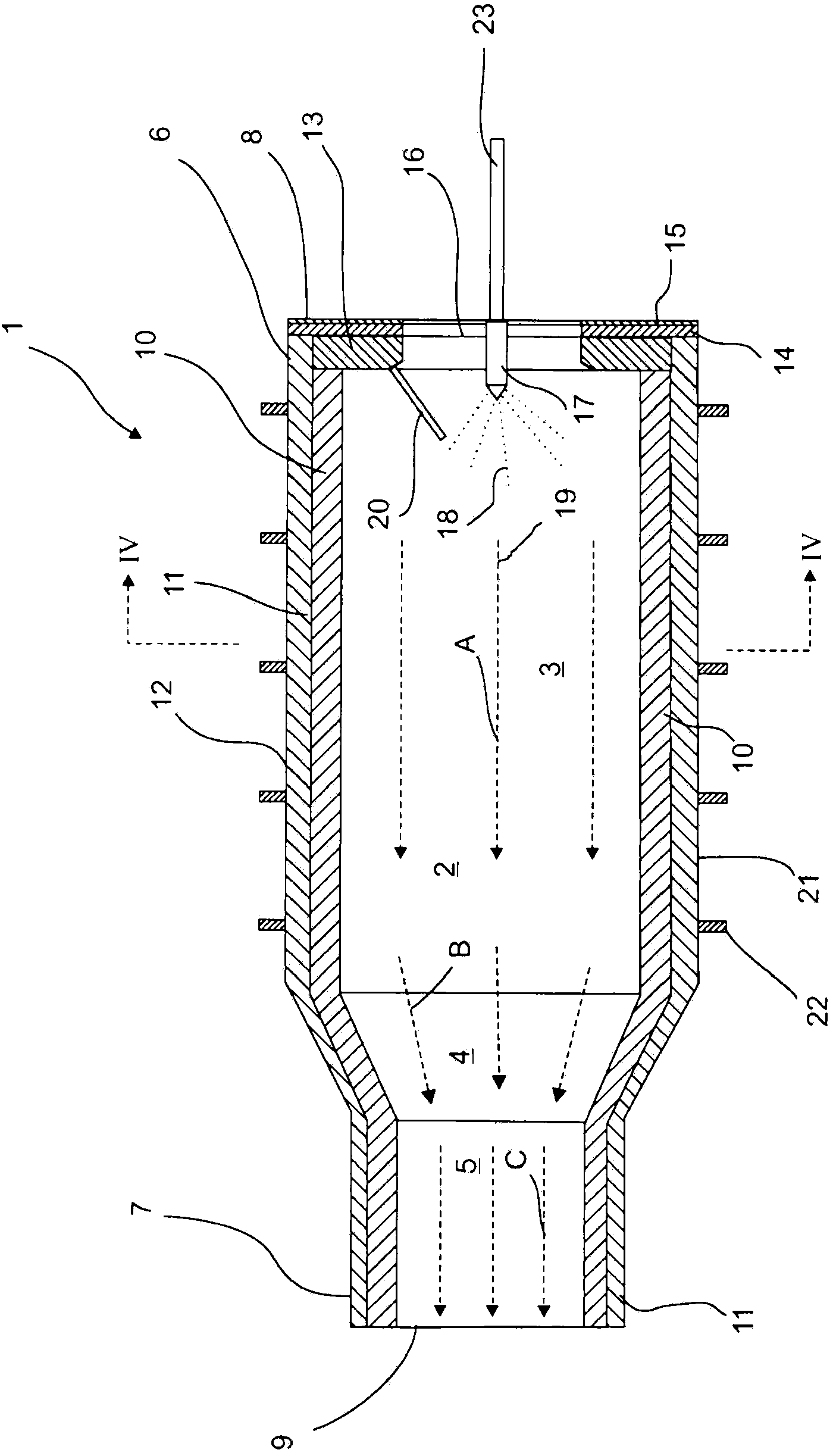

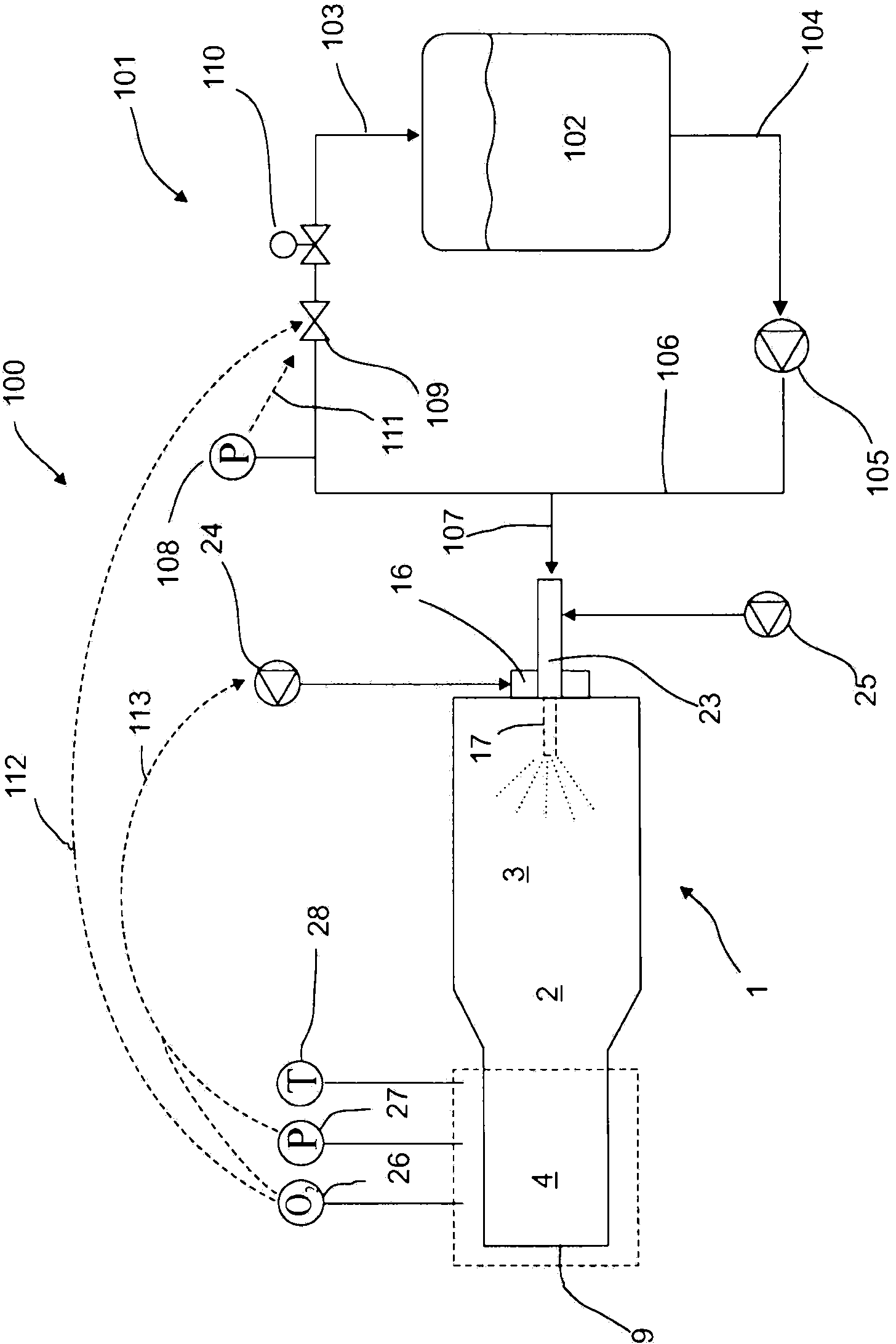

[0056] figure 1 A cutaway side view of a device 1 for combusting a fluid fuel according to the invention is shown. The device 1 has a combustion compartment 2, wherein the compartment 2 is used to combust a fluid fuel. The combustion compartment 2 can be divided into an incineration / combustion chamber 3 , in which the actual combustion of the fuel is performed, and an exhaust chamber 5 , which enables exhaust gases resulting from the combustion to leave the device 1 . The combustion chamber 3 may have a first cross-sectional diameter which is greater than a second cross-sectional diameter of the discharge chamber 5, wherein the transition from the first cross-sectional diameter to the second cross-sectional diameter is in the transition chamber / volume 4 for gradients.

[0057] The combustion chamber has a proximal end 6 with a closed end 8 and a distal end 7 with an open end 9 . Within the meaning of the present invention, the terms "open" and "closed" in relation to the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com