An automatic riser clamping tool

A technology for clamping tooling and removing risers, which is applied in the field of automatic riser-removing clamping tools, can solve problems such as the lack of universality of the riser-removing mechanism, and achieve the effects of avoiding deformation, preventing crushing, and reducing rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

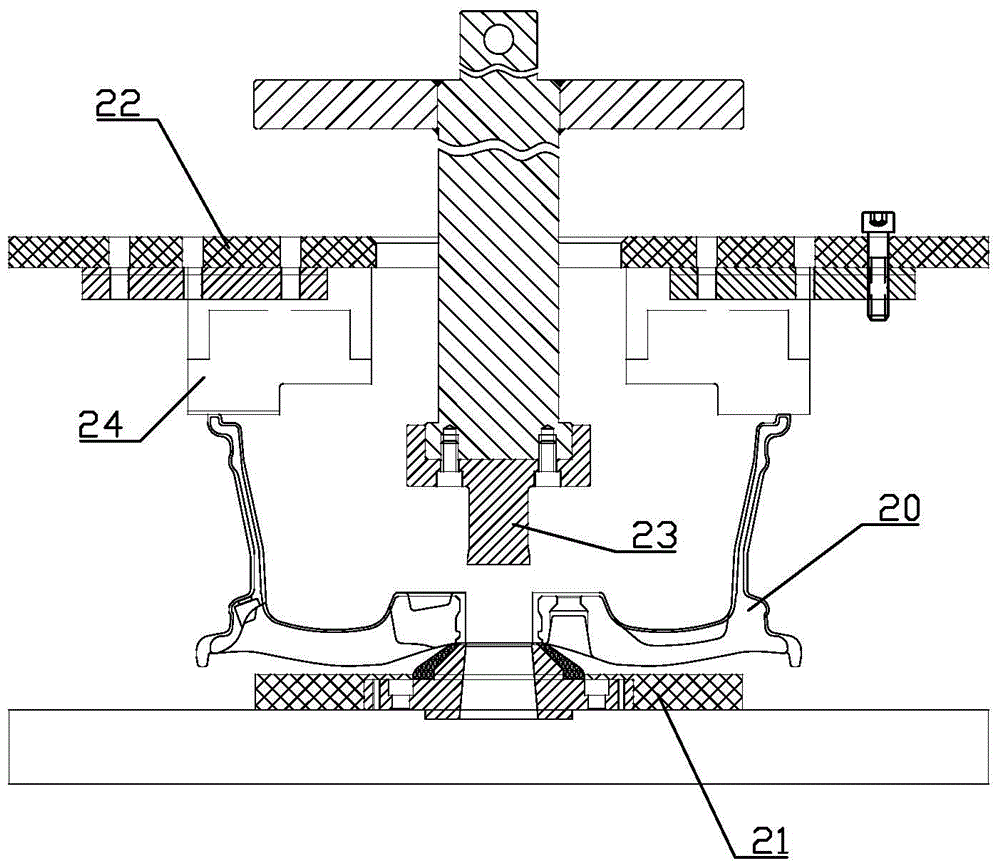

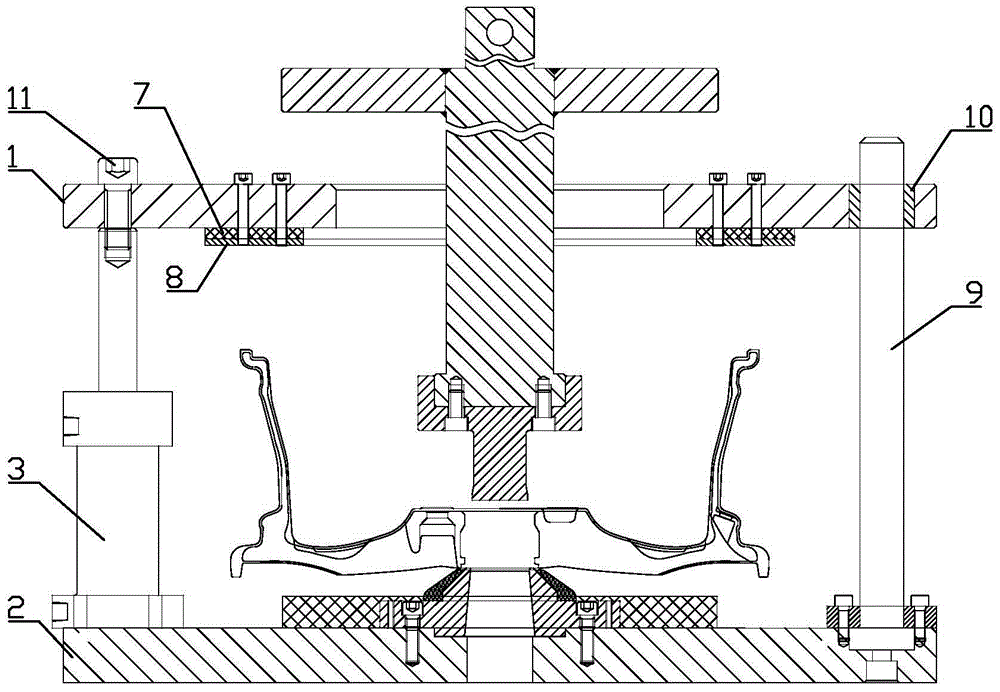

[0018] Such as figure 2 The automatic de-riser clamping tool shown includes clamping device and hydraulic system.

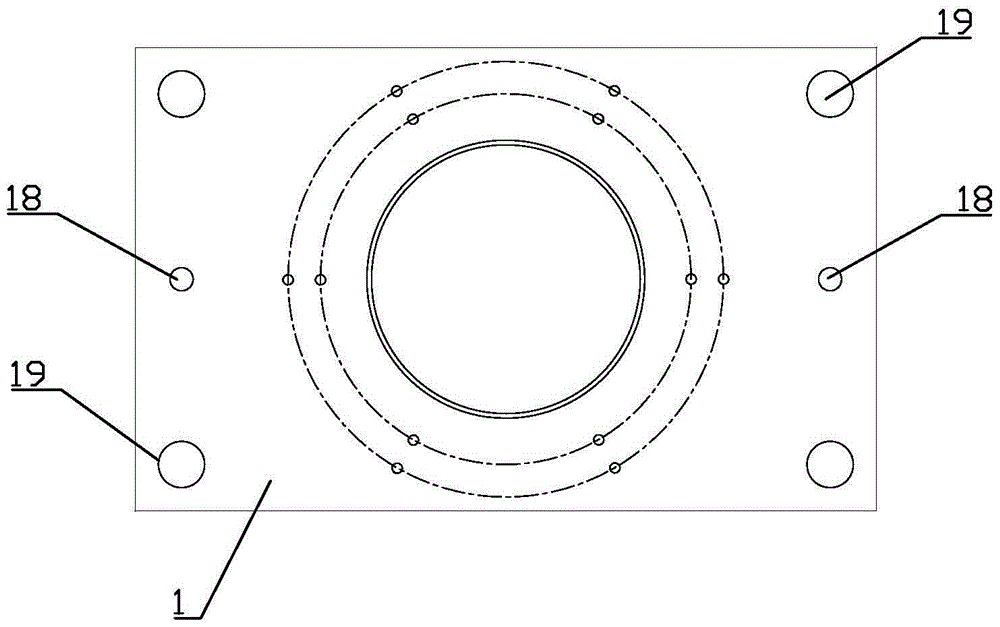

[0019] Wherein the clamping device includes an upper template 1 and a base 2 . The base 2 is fixed, and the hub is placed on the base 2 . The upper template 1 is above the base 2, which is rectangular and can move up and down relative to the base 2. There is a round hole in the middle of the rectangle. The punch of the punching machine can pass through the round hole, so as to raise the hub under the upper template 1. punching. The bottom of the upper template 1 is equipped with a pressing unit for pressing the rear rim of the wheel hub.

[0020] The base 2 is provided with two two-way oil cylinders 3, and each two-way oil cylinder 3 is symmetrically arranged on the left and right with respect to the center of the upper formwork 1, and the corresponding output shafts of each two-way oil cylinder 3 are fixedly connected to the left and right sides of the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com