Manual pipe clamp

A pipe clamp and clamping device technology, applied in clamping, manufacturing tools, workpiece clamping devices, etc., can solve the problems of operator's personal safety hazards, large force, damage to items, etc., and achieve less danger, improved safety, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

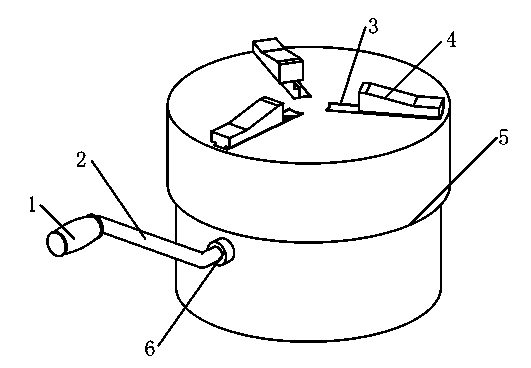

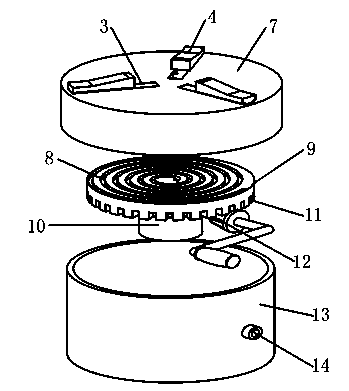

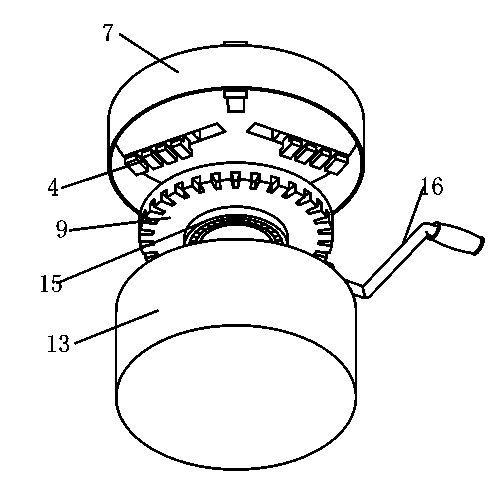

[0021] Embodiment 2: as figure 1 , figure 2 and image 3 As shown, a manual pipe clamp, housing 5, clamping device 4, compass 9 and rocker 2, housing 5 is composed of upper housing 7 and lower housing 13, upper housing 7 is installed on the lower housing 13, compass 9 is fixed on the lower shell 13, the upper shell 7 is provided with a clamping track 3, the clamping device 4 is arranged on the clamping track 3, the number of the clamping track 3 is greater than or equal to 3, and the clamping track 3 is arranged radially On the upper casing 7, the upper surface of the compass 9 is provided with a spiral track 8, the spiral track 8 is in the shape of an Archimedes spiral, and the lower end of the clamping device 4 is provided with a protrusion 16, and the protrusion 16 is engaged on the spiral track 8, the lower surface of the compass 9 is provided with a gear pattern 11, the rocker 2 is installed on the lower housing 13, and one end of the rocker 2 is provided with a bevel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com