A hot press molding system for foamed products

A technology of thermoforming and foaming products, which is applied in the field of production equipment of foaming products, can solve the problems of unfavorable enterprise cost control, cost increase, high molding pressure, etc., achieve good cold and heat treatment conditions, save costs and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

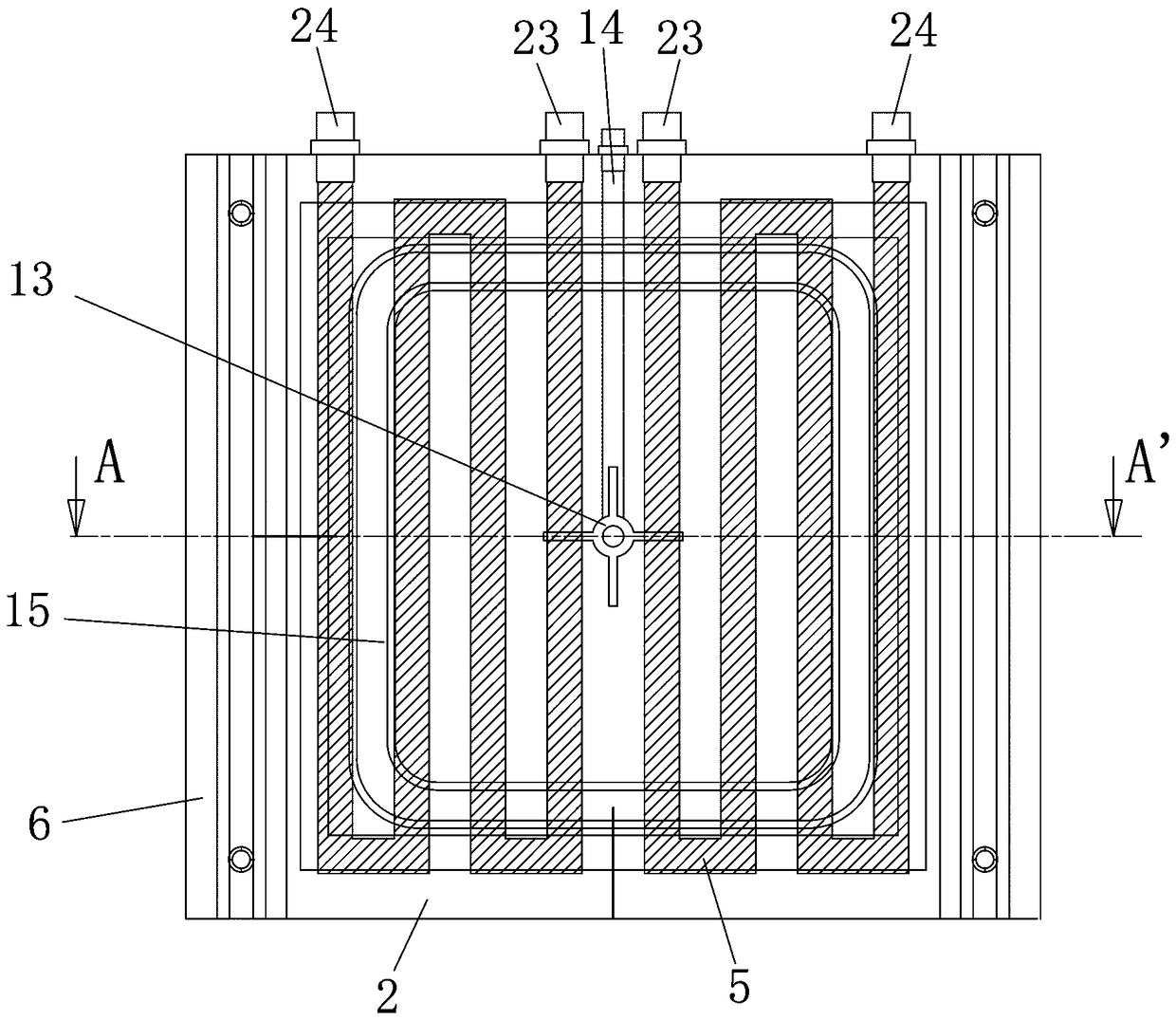

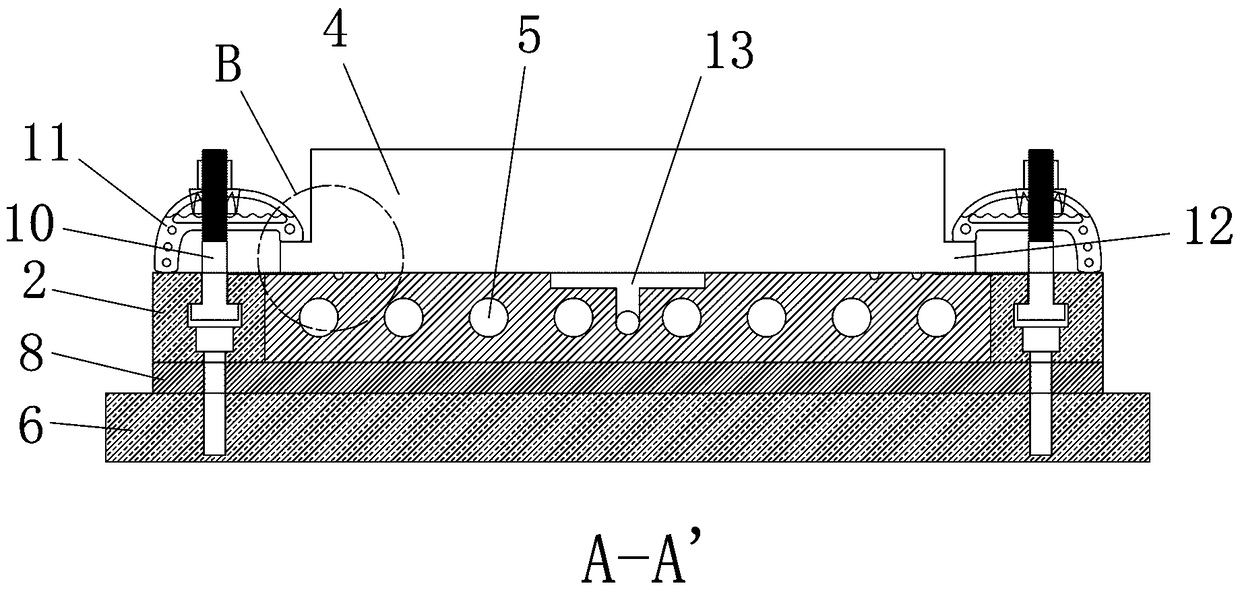

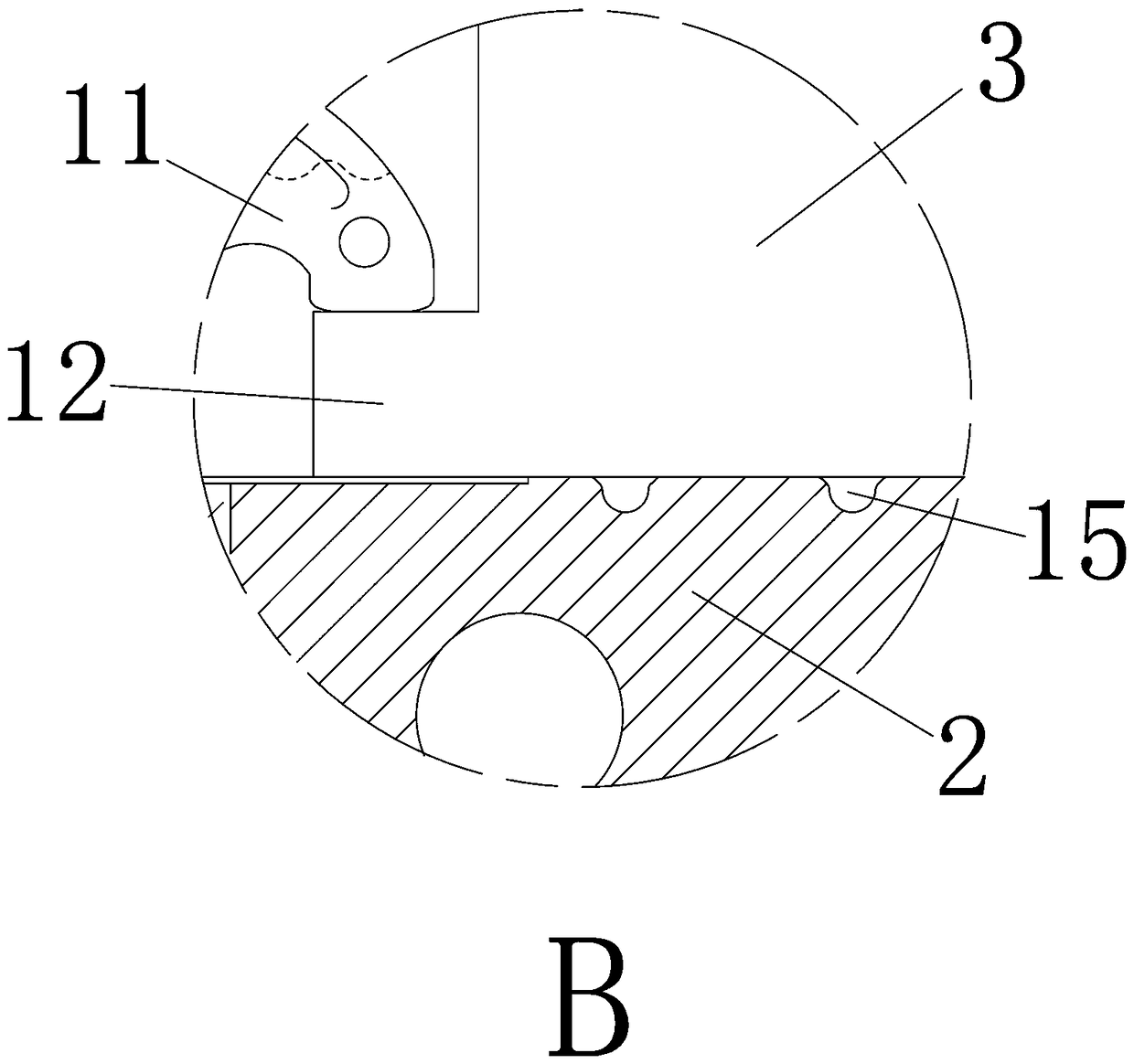

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] like Figures 1 to 7 As shown, a thermocompression molding system for foamed products includes an upper mold frame 1, a lower mold frame 2, an upper mold 3, a lower mold 4 and a cooling and heating cycle system, and the upper mold 3 is installed on the upper mold frame 1 , the lower mold 4 is installed on the lower mold frame 2, and the upper mold frame 1, the lower mold frame 2, the upper mold 3 and the lower mold 4 are all equipped with a heat transfer medium for the circulation of the cold and heat circulation system. The hot channel 5, the cooling and heating cycle system conducts heat transfer with the upper mold frame 1, the lower mold frame 2, the upper mold 3 and the lower mold 4 at a specified time through at least three heat transfer media of different temperatures. The upper formwork 1 and the lower formwork 2 are made of aluminum. The at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com