Ink jet type label printer

An inkjet print head and printer technology, applied in printing devices, printing and other directions, can solve the problems of slow ticket printing, high cost of consumables, poor printing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

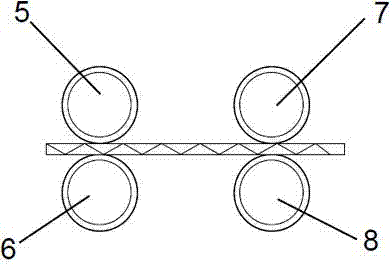

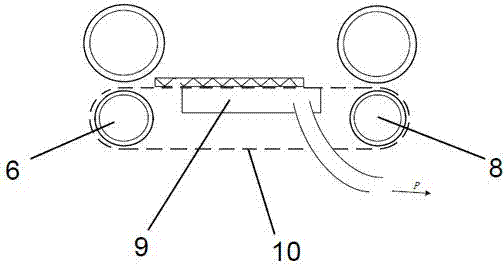

[0050] With reference to the accompanying drawings, the inkjet type ticket printer includes a frame, and two sets of front and rear transmission wheels installed on the frame, each group of transmission wheels is divided into upper and lower transmission wheels, and the lower transmission wheel of the paper feeding end transmission wheel After being connected with a driving motor, it is driven and connected with the lower drive wheel 8 at the paper output end through a transmission belt 10; inkjet printing heads 101-104 are installed above the support plate, and a drying device 17 is installed at the paper output end of the inkjet printing head.

[0051] The drying device is a curved surface, and the heating element used is a ceramic sheet.

[0052] In the above-mentioned inkjet ticket printer, a printing medium conveying belt 18 is installed on the front and rear lower driving wheels, and the printing medium conveying belt is composed of a base material 15 and a surface adhesi...

Embodiment 2

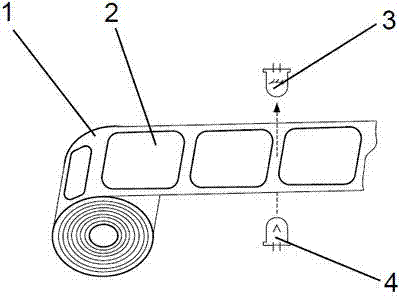

[0060] Different from Embodiment 1, this embodiment is provided with photoelectric sensors 3 and 4 at the paper feeding end of the transmission wheel. It is used for printing continuous self-adhesive label paper with face paper spaced on the bottom paper.

Embodiment 3

[0062] In this embodiment, UV ink is used for printing, and the heating element of the heating device is a UV light source.

[0063] UV ink is ultraviolet curable ink, which can undergo cross-linking reaction under the irradiation of ultraviolet (UltraViolet) light waves, and instantly change from liquid to solid ink. Its main components include photopolymerizable prepolymers, photosensitive monomers, organic pigments, photopolymerization initiators, and additives. Among them, the photopolymerization initiator is the most important component in the UV ink, and it is the beginning of the photopolymerization reaction. Commonly used photopolymerization initiators include aromatic ketones and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com