Middle axle moment sensing system of electric bicycle with built-in motor

一种电动自行车、传感系统的技术,应用在车辆部件、乘骑者驱动、运输和包装等方向,达到保证流畅感、增加舒适度、克服常见缺陷的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

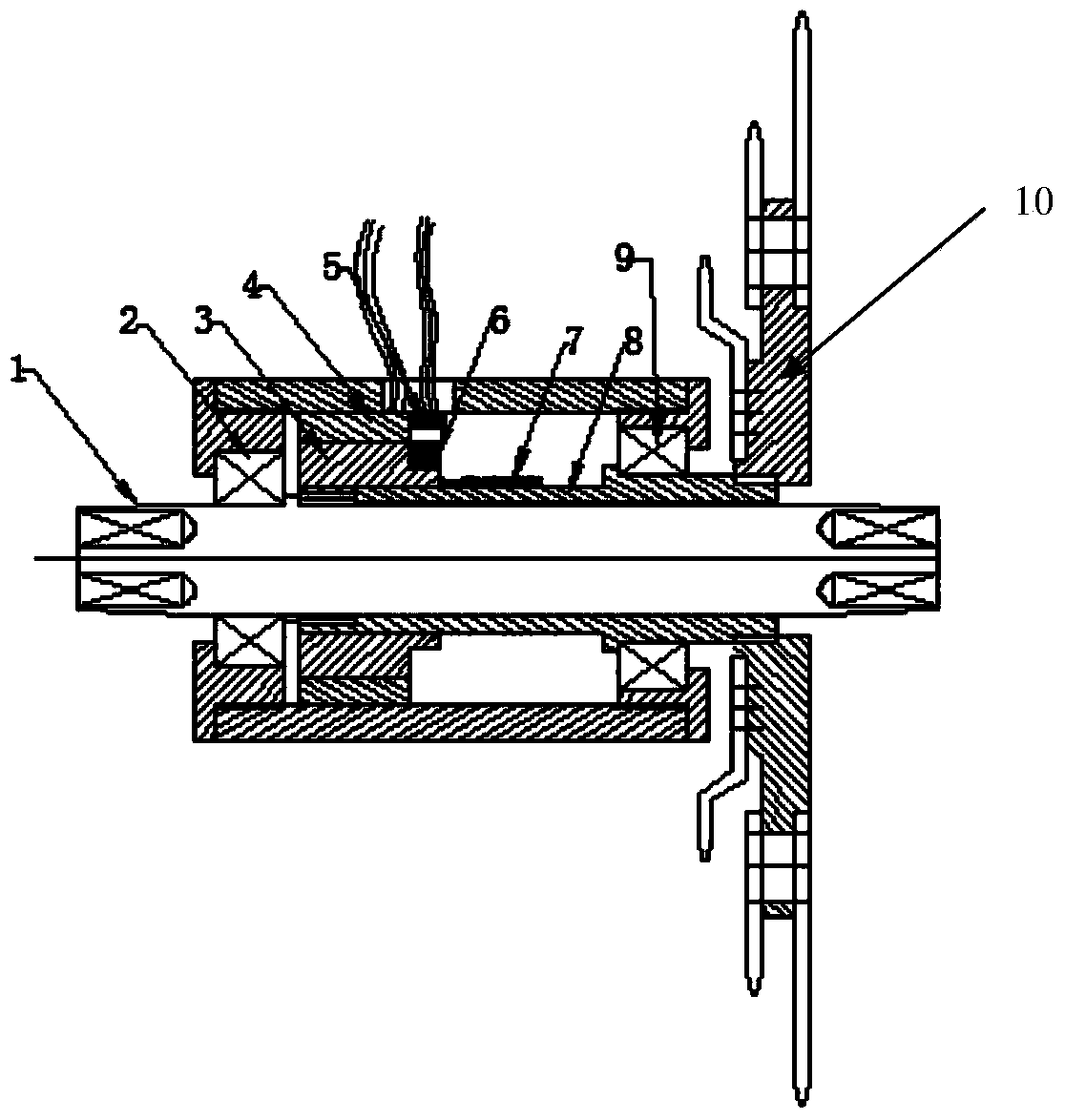

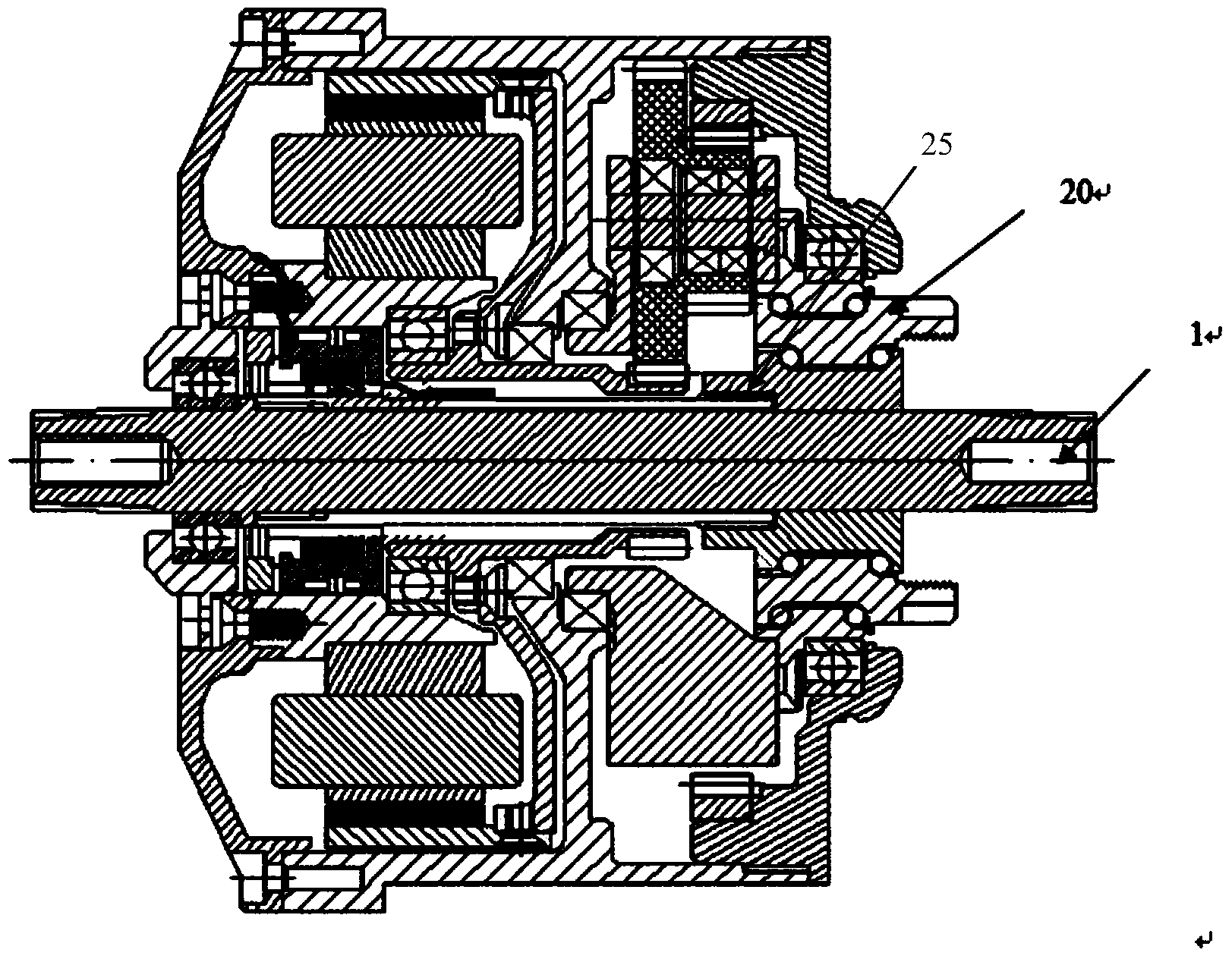

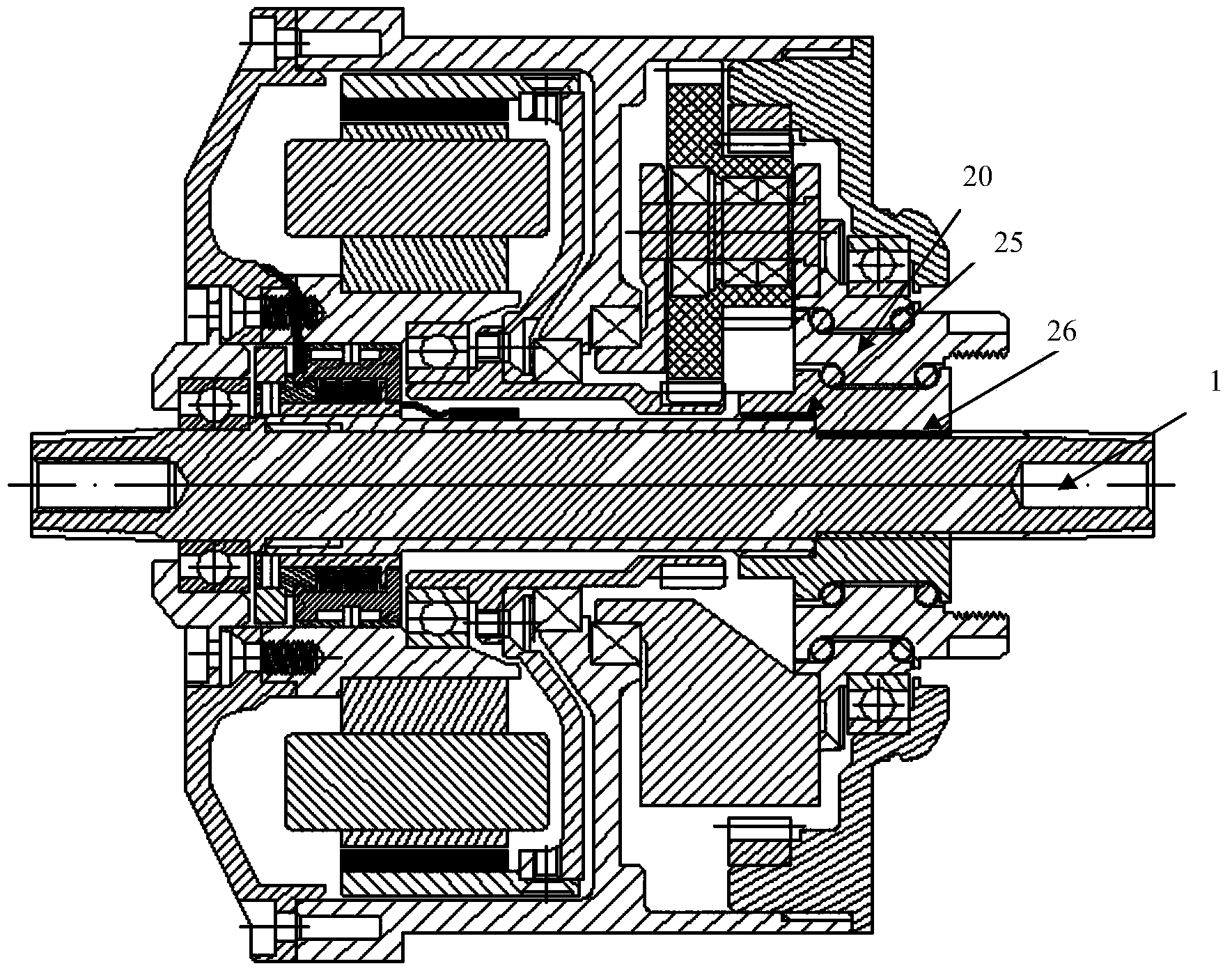

[0028] refer to figure 1 and 5 , the present invention provides a center shaft torque sensing system for an electric bicycle with a central motor, which includes a center shaft 1, a strain sleeve 8, a sprocket bracket 10, a torque sensor 7 and a bottom bracket, and one end of the strain sleeve 8 passes through a bearing 2. It is fixed on the bottom bracket and connected with the sprocket bracket 10. The other end is set on the center shaft 1 and is fixedly connected with the center shaft. The inner surface of the strain sleeve fits the outer surface of the center shaft. The sleeve and the center shaft only There will be a relative micro-rotation without shaking up and down and left and right. When the foot pedals, no matter the left foot or the right foot, the pedaling force is transmitted to the strain sleeve 8 through the connection between the central axis and the sleeve, and the other end of the sleeve transmits the pedaling force through the chain wheel bracket 10 Get o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com