A fairing windshield with anti-rain function

A technology of fairing and windshield, applied in the field of launch vehicle body structure, to achieve the effect of strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

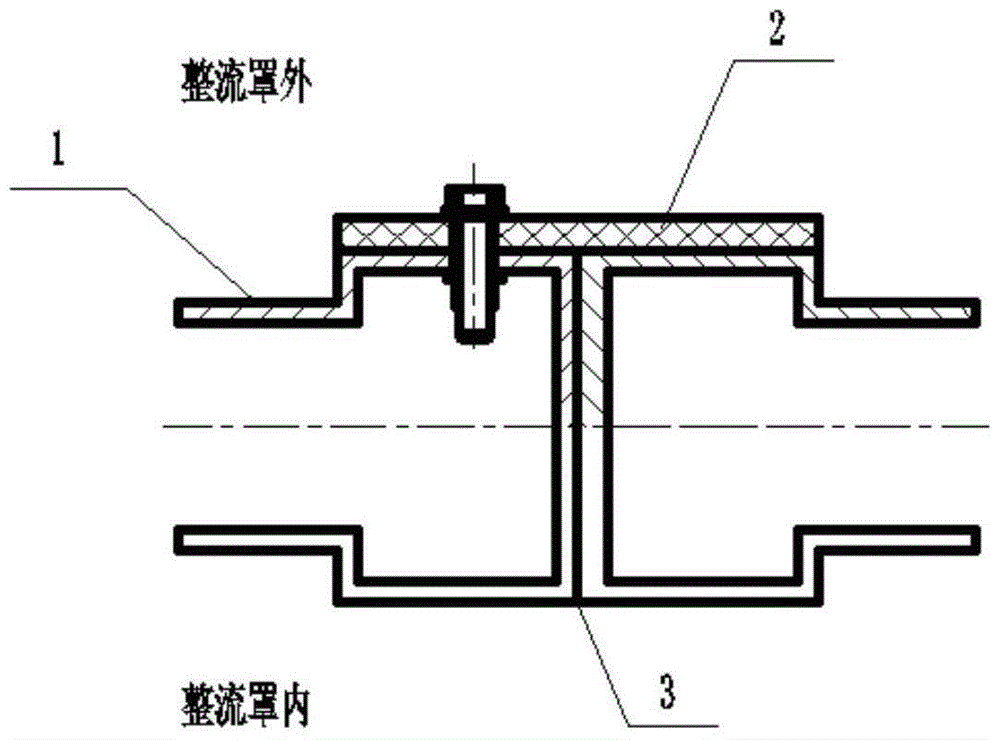

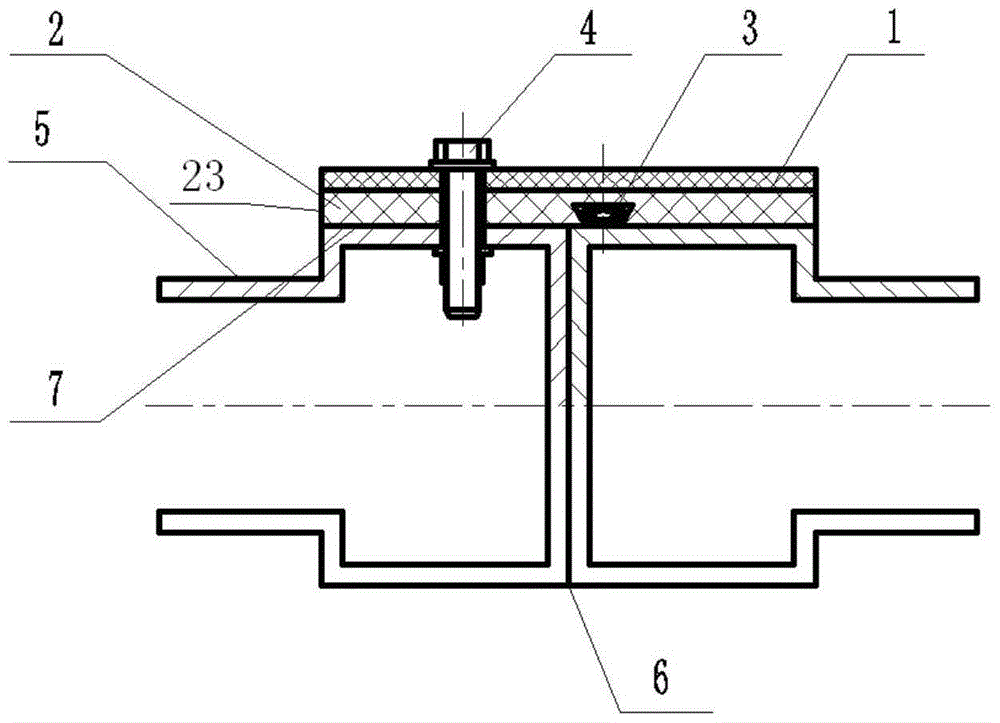

[0020] The fairing windshield according to the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

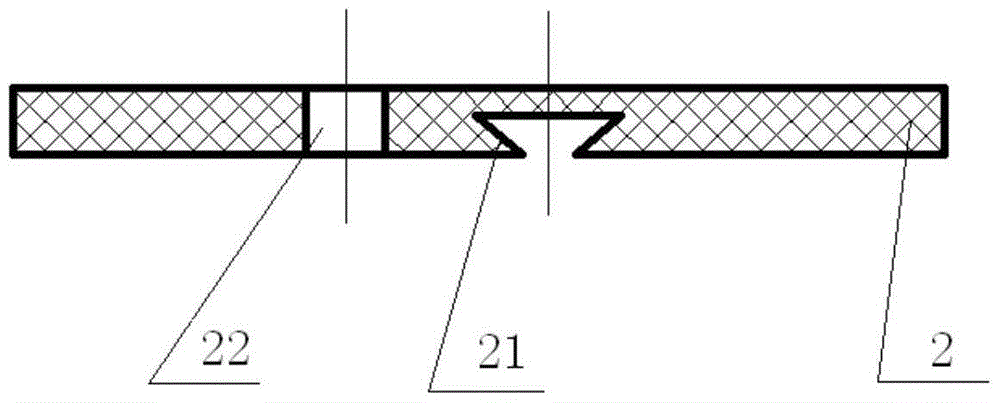

[0021] According to the fairing windshield of the present invention, it comprises a laminated glass cloth plate 2, a glass steel plate 1 and an O-ring seal 3, with reference to figure 2 and Figure 6 . The glass steel plate 1 is bonded to the upper surface of the laminated glass cloth plate 2 . A dovetail groove 21 is processed on the lower surface of the laminated glass cloth plate 2, and the width of the notch of the dovetail groove 21 is smaller than the width of the bottom of the groove, and the O-shaped sealing ring 3 is compressed and fitted in the dovetail groove 21, and partially protrudes on the laminated glass cloth plate 2; coaxial bolt mounting holes 11, 22 are arranged on the glass steel plate 1 and the laminated glass cloth plate 2, and the positions of the two bolt mounting holes 11, 22 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com