Belt breakage protecting device of belt conveyor

A technology for protection devices and broken belts, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as unfavorable broken belt protection, high precision requirements, alignment problems, etc., to achieve manpower saving and safety Good sex and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further describe the present invention below in conjunction with embodiment and accompanying drawing. The specific embodiments are only used to describe the present invention in detail, and do not limit the protection scope of the claims of the present application. At the same time, all the different specific implementation modes produced by referring to the prior art are the specific implementation modes of the present invention.

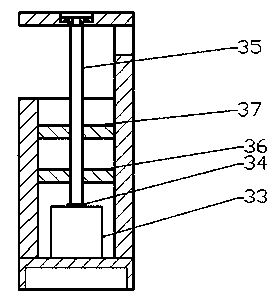

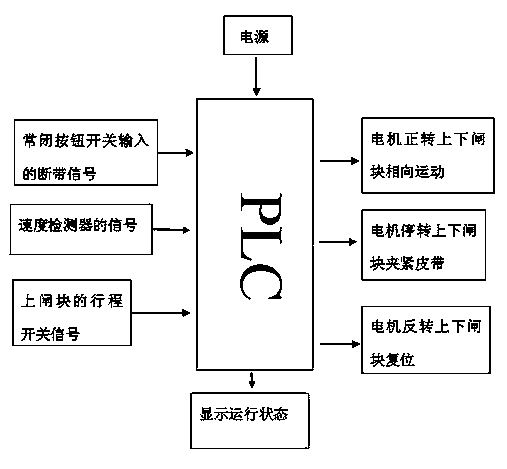

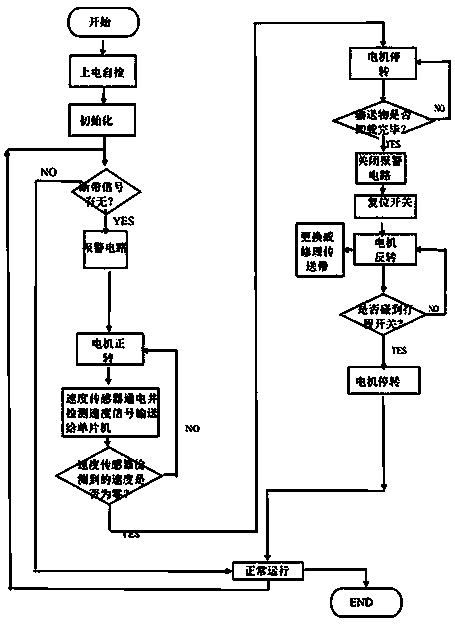

[0022] The conveyor belt of the belt conveyor designed by the present invention, the conveyor belt or the broken belt protection device (referred to as the broken belt protection device, see Figure 1-7 ), adopts a modular design, and is mainly composed of a frame 1, a support roller 2, a catcher 3, a detection device 4 and a control system 5; it is characterized in that the catcher 3 and the detection device 4 are actively implemented as follows Improve:

[0023] The catcher 3 is composed of a support web 31, a screw guide mechanism 32, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com