Pressure-superposed water supply pumping station

A technology of water pumps and pumping stations, which is applied in the field of superimposed water supply pumping stations with water tanks, which can solve problems such as difficult control methods, poor energy saving effects, and large water pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

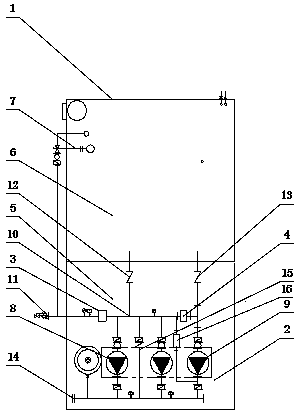

[0007] Such as figure 1 A stacked feedwater pumping station shown includes: shell 1, water pump unit 2, tap water protection device 3, normally open solenoid valve 4, normally closed solenoid valve 16, control cabinet (not marked in the figure) and valves. Body 1 is divided into equipment room 5 and water storage room 6, tap water is connected to water storage room 6 through float valve 7, water pump unit 2 is divided into stack pump 8 and booster stack pump 9, tap water protection device 3 adopts hydraulic control, The higher the tap water pressure is, the larger the opening is and the more the excess flow is. The water inlet of the stack pump 8 is connected to the water inlet pipe 10, the water outlet of the stack pump 8 is connected to the water outlet pipe 14, and the inlet of the booster stack pump 9 passes through. The normally open solenoid valve 4 is connected to the water inlet main pipe 10, the inlet of the booster stack pump 9 is connected to the water storage room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com