Exhaust gas extraction system of medium speed coal mill

A coal mill and medium-speed technology, applied in the field of medium-speed coal mill exhaust gas extraction system, can solve problems such as uneven distribution of coal powder, abnormal combustion of boiler furnaces, etc., and achieve the effects of precise distribution, small impact, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

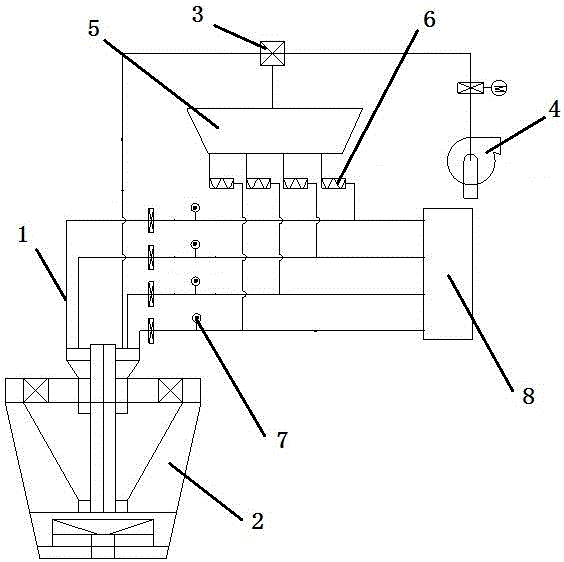

[0012] Five evenly distributed primary air pipes 1 are fixedly connected to the outlet separator 2 of the medium-speed coal mill, and one of the primary air pipes is connected to the bag filter 3, which is also connected to the induced draft fan 4. The bag filter The bottom is connected with the powder bin 5, and the bottom of the powder bin is respectively connected with four powder feeders 6, and the top of the remaining four of the five primary air ducts 1 are respectively fixedly connected with a continuous curve-shaped shrinkage cavity device 7, and the powder feeder 6 passes through The pipelines are respectively connected with the remaining four primary air pipes, and the remaining four primary air pipes are connected with the furnace 8 .

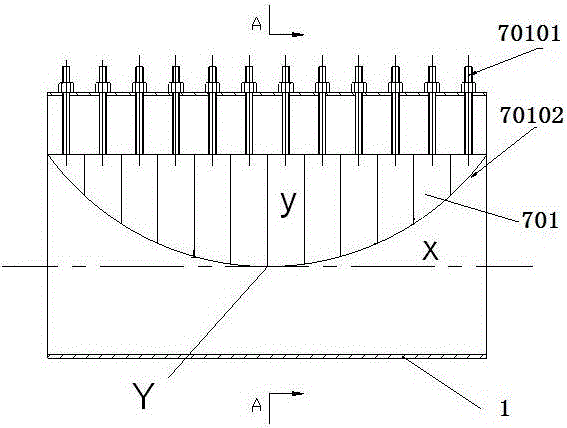

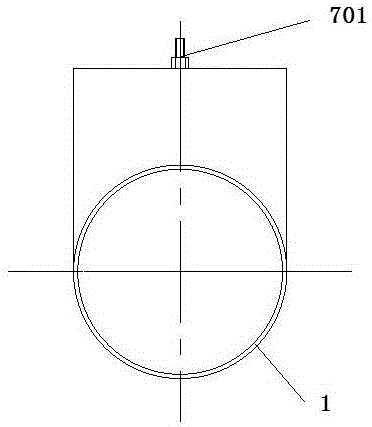

[0013] The structure of the continuous curve type regulating shrinkage cavity device of the present invention is: a row of regulating shrinkage holes 701 is installed on the primary air duct 1, and the row of regulating shrinkage hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com