Method for gassing bioreactors and gassing system

A bioreactor and gas supply system technology, applied in specific-purpose bioreactors/fermenters, methods for supporting/fixing microorganisms, bioreactor/fermenter combinations, etc., to achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

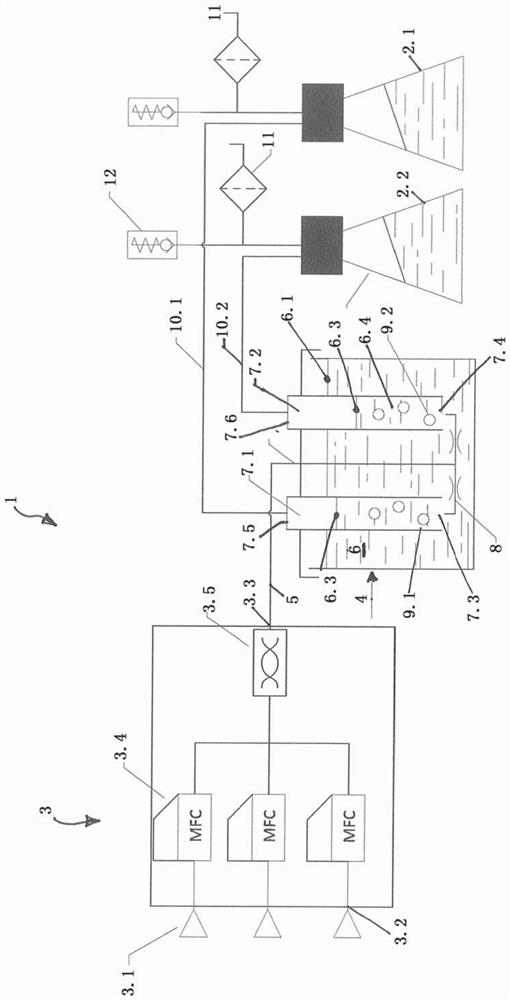

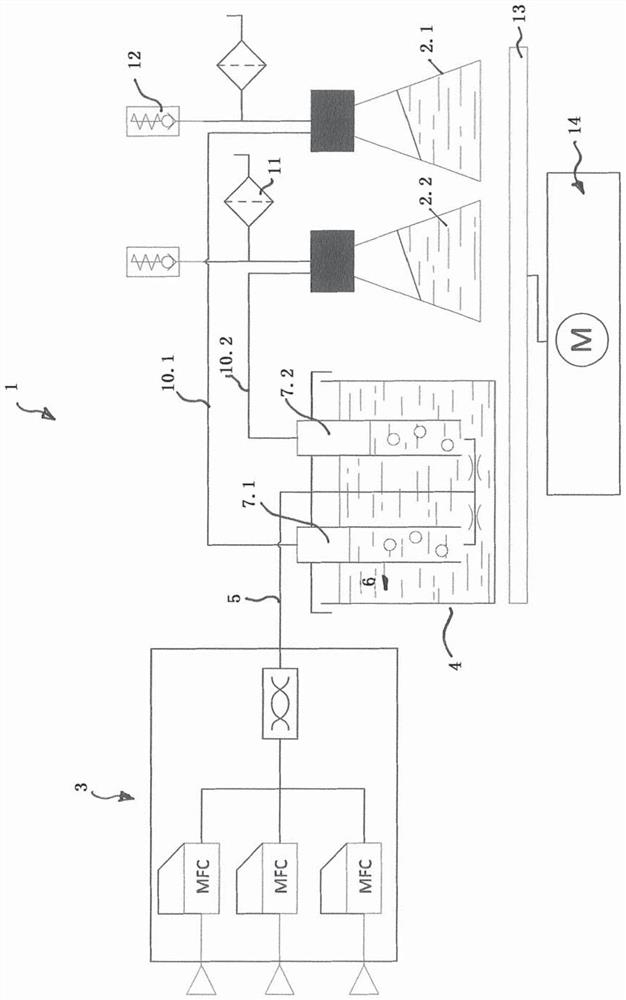

[0041] figure 1 A schematic diagram of a gas supply system (1 ) for supplying gas to a plurality of bioreactors (2.1, 2.2) is shown. In the examples, only two bioreactors are shown for reasons of clarity. However, with the gas supply system according to the invention, more than two, for example six, bioreactors can be gassed simultaneously without difficulty. The bioreactors (2.1, 2.2) are designed to accommodate biomass, liquid culture medium and to introduce a gas supply.

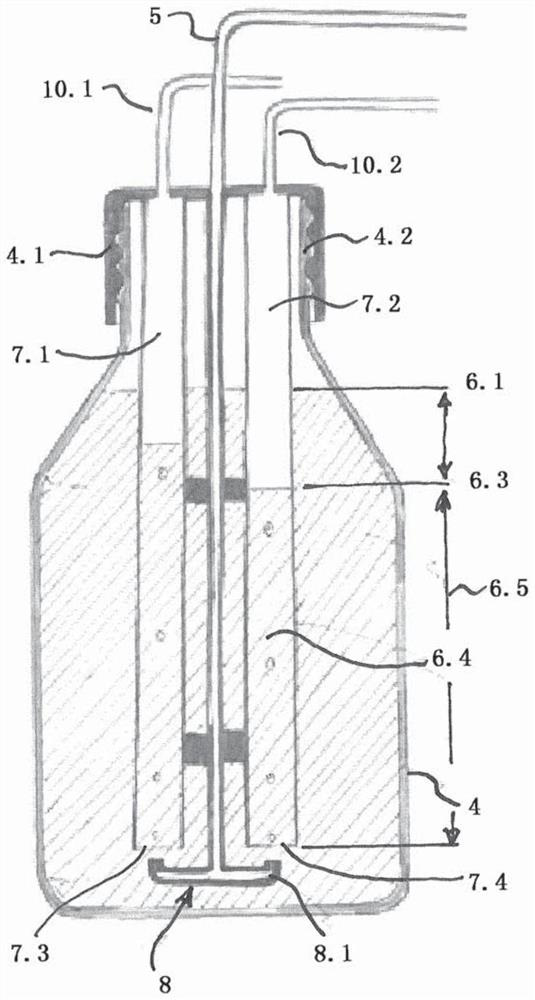

[0042] As another important part, the gas supply system (1) includes a gas supply device (3) and a container (4) for providing a constant air flow, the air flow contains a mixture of three gases in the embodiment, the container is set to humidify the airflow and divide it into partial airflows.

[0043] The container (4) contains a liquid fill (6) into which the ascending lines (7.1, 7.2) are immersed perpendicularly to the liquid level (6.1). The ascending lines (7.1, 7.2) are implemented as tubes fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com