Electromagnetic gun bullet and rail gun

A shell and electromagnetic technology, applied in the field of shells, can solve problems such as increased friction, guide rail ablation, and maximum current limitation, and achieve the effects of enhanced contact performance, simple structure, and high initial firing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

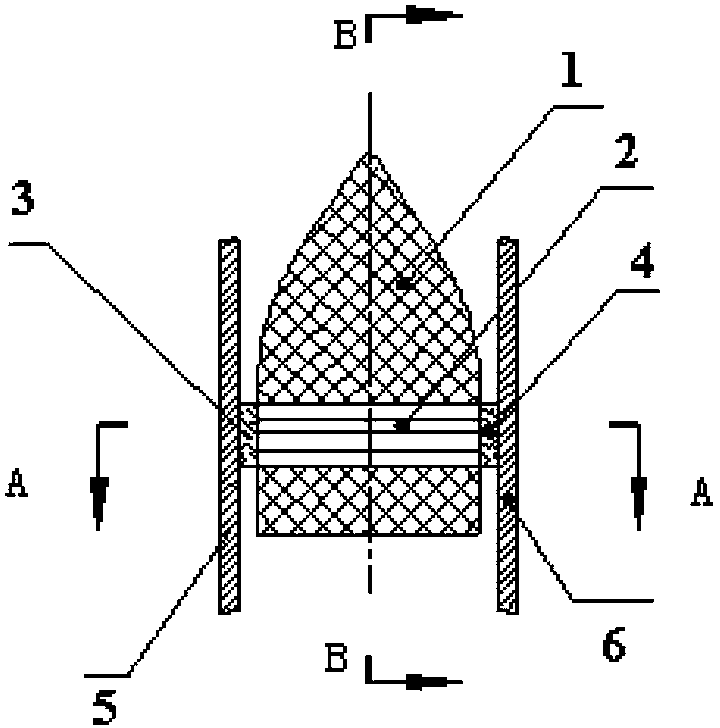

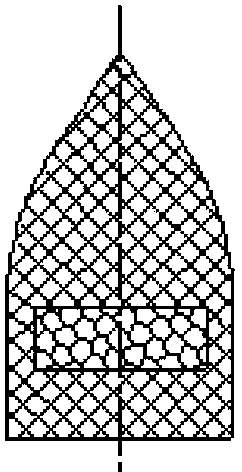

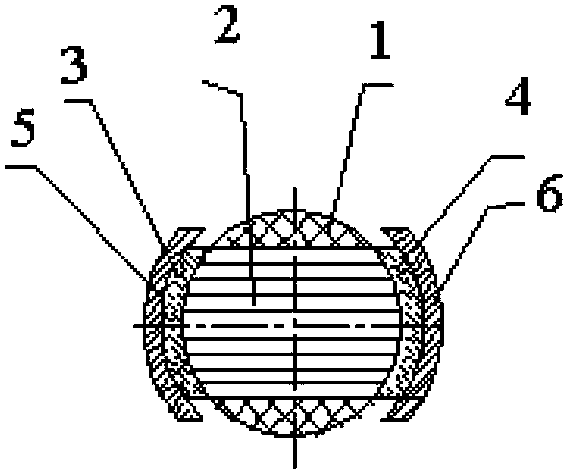

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

[0019] like Figure 1-3 As shown, the present invention provides an electromagnetic gun projectile, including a projectile body and an armature; the armature includes an armature body, a left carbon brush and a right carbon brush; the left carbon brush is glued to the left end of the armature body Then, the right carbon brush is bonded to the right end of the armature body; the armature body is bonded to the projectile body; the armature body is a non-metallic fiber conductor. The armature body and the projectile body are bonded by thermosetting resin. or other bonding materials. The fiber conductor of non-metallic material is composed of a group of non-metallic fibers arranged in parallel or non-parallel in the same direction.

[0020] It should be noted that in the present invention, the non-metallic fiber used for the armature body can be an existing non-metallic fiber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com