LED display device space position detection method and system for guidance and correction

A display device and detection method technology, applied in the direction of using optical devices, measuring devices, static indicators, etc., to achieve the effects of improving the calibration process, flexible operation, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

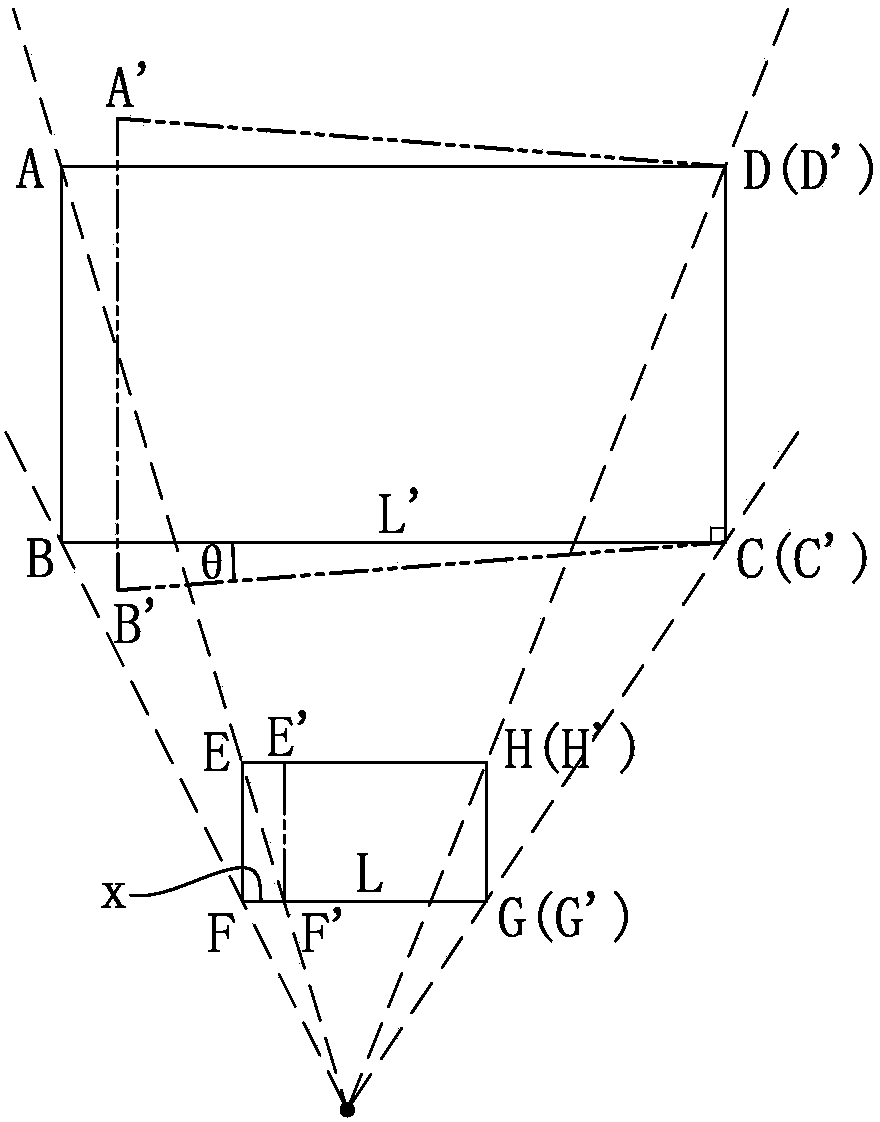

[0032] For the calibration of LED display devices such as LED cabinets in factory mode, the deviation of LED brightness and chromaticity measurement caused by human errors is reduced by intelligently detecting the relative spatial position between the shooting equipment such as a camera and the LED cabinet to be corrected. The specific implementation methods are as follows: as follows:

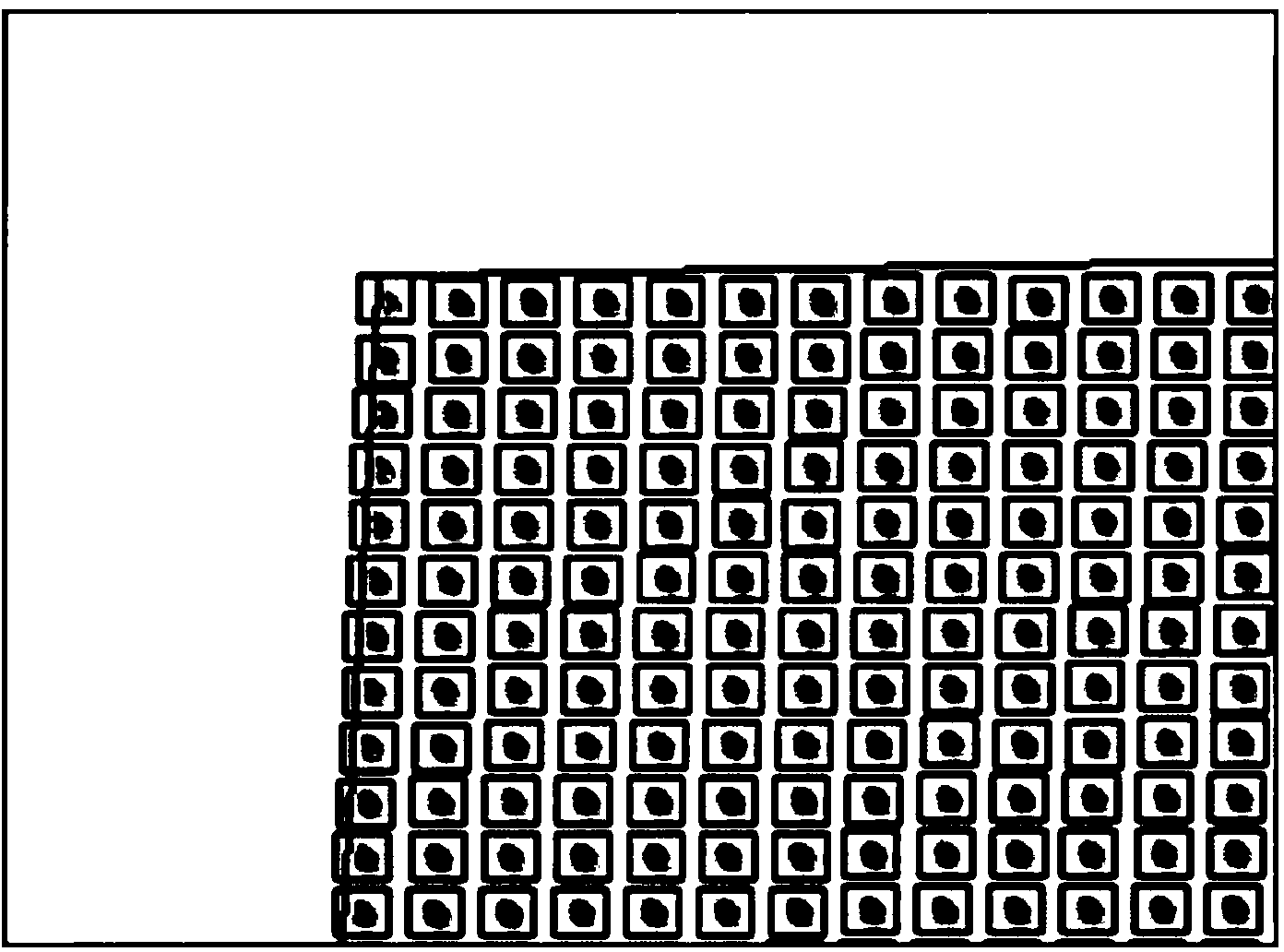

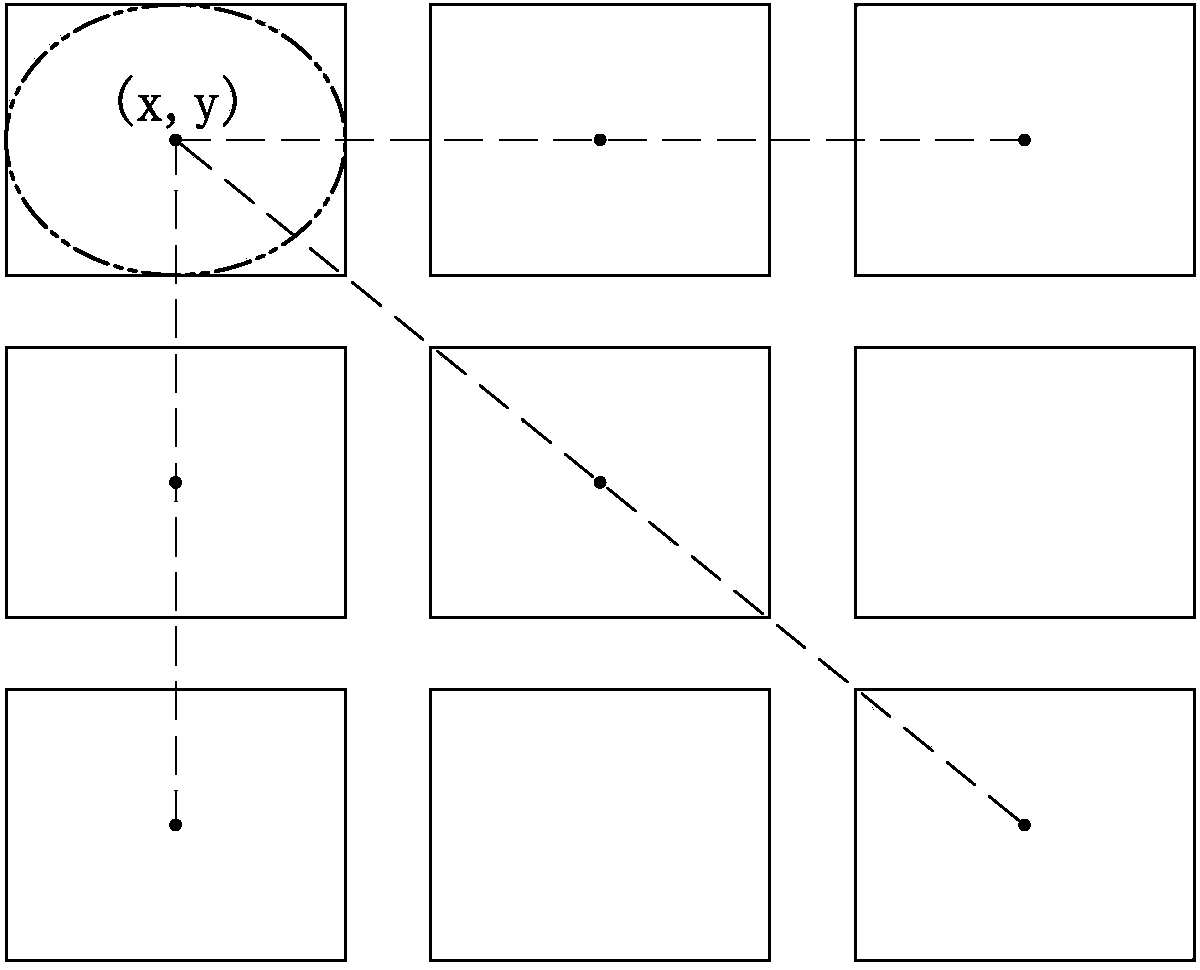

[0033] (1) Obtain any single-color LED cabinet image of red, green, and blue, and locate each LED light point of the LED cabinet to be corrected in the LED cabinet image through image processing and analysis technology. Specifically, it can be: control the LED box to be corrected to display any monochrome picture of red, green, and blue and control the camera to capture the displayed monochrome picture, then the LED box image can be obtained, which is also called the detection of the monochrome image; and then through Image processing and analysis technology locates multiple LED light points o...

no. 2 example

[0045] For the calibration of LED display devices such as LED cabinets in factory mode, the deviation of LED brightness and chromaticity measurement caused by human errors is reduced by intelligently detecting the relative spatial position between the shooting equipment such as a camera and the LED cabinet to be corrected. Another specific implementation The way, for example, is as follows:

[0046] (1) Obtain any single-color LED cabinet image of red, green, and blue, and locate each LED light point of the LED cabinet to be corrected in the LED cabinet image through image processing and analysis technology. Specifically, it can be: control the LED box to be corrected to display any monochrome picture of red, green, and blue and control the camera to capture the displayed monochrome picture, then the LED box image can be obtained, which is also called the detection of the monochrome image; and then through Image processing and analysis technology locates multiple LED light poi...

no. 3 example

[0057] See Figure 9The third embodiment of the present invention provides a system for detecting the spatial position of an LED display device for guiding correction, which is suitable for performing the detection of the spatial position of an LED display device for guiding correction in the aforementioned first embodiment and / or the second embodiment method. Specifically, the LED display device spatial position detection system 90 for guiding correction in this embodiment includes: a shooting control module 91 , a light point selection and center coordinate calculation module 93 , a spatial state difference calculation module 95 and an adjustment prompt output module 97 . Wherein, the photographing control module 91 is used to control the photographing equipment to photograph a monochromatic picture displayed by the LED display device (such as an LED box) to be corrected to obtain a detected monochromatic image and locate the subject to be corrected in the detected monochrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com