Environment-friendly cable

An environmentally friendly and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve a large number of problems that hinder fire fighting work and personnel evacuation, corrode instruments and equipment, etc., achieve low flammability, ensure insulation performance and flame retardancy , Improve the effect of flame retardant grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

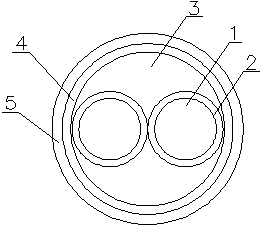

[0009] An environment-friendly cable includes two cable cores, a filling layer 3, a shielding layer 4 and a sheath layer 5. The cable core includes a conductor 1 and an insulating layer 2 covering it, and the filling layer 3 is covered on Outside the cable core, the shielding layer 4 is covered outside the filling layer 3, the sheath layer 5 is covered outside the shielding layer 4, and the insulating layer 2 is a low-smoke, halogen-free, flame-retardant cross-linked polyolefin insulating layer, The filling layer 3 is a glass fiber rope filling layer, the shielding layer 4 is a braided copper wire shielding layer, and the sheath layer 5 is a low-smoke, halogen-free, flame-retardant cross-linked polyolefin sheath layer.

[0010] The conductor 1 of the present invention is composed of multiple twisted tinned copper wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com