Self-lifting rotary insulation cage

A rotary and working bucket technology, which is applied in the direction of lifting devices, overhead lines/cable equipment, etc., can solve the problems of high risk factors for electric workers working at heights, high requirements for insulation auxiliary isolation measures, and cracks, etc., to achieve the reduction of climbing poles The effect of reducing labor intensity, expanding the operable range, and improving the insulation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

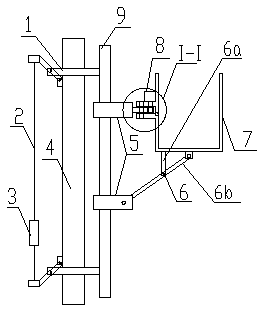

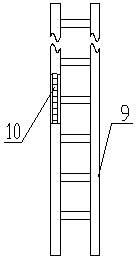

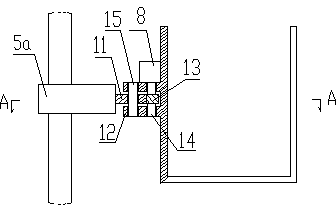

[0016] In the figure, the self-elevating and rotatable insulating working bucket includes an insulating rack frame 9, a lifter 5, a self-locking segmented hoop 1 and a working bucket 7, and racks 10 are arranged on both sides of the insulating rack frame. , the lifter is spaced up and down and is movably connected with the insulating rack frame 9. The lifter includes a housing 5a, and the two ends respectively support the pin shaft 16 which is arranged on the housing and are fixedly arranged on the pin shaft and connected with the gear The elevating gear 18 that is meshed with the bar 10 is fixedly provided with a circular arc-shaped connecting gear plate 11 on one side of the shell of the lifter on the upper part of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com