A kind of nesting material for artificial breeding of wasps

A wasp and artificial technology, applied in the field of wasp breeding, can solve problems such as low efficiency and difficulty in nesting, and achieve the effects of shortening nesting time, increasing income, and promoting egg-laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

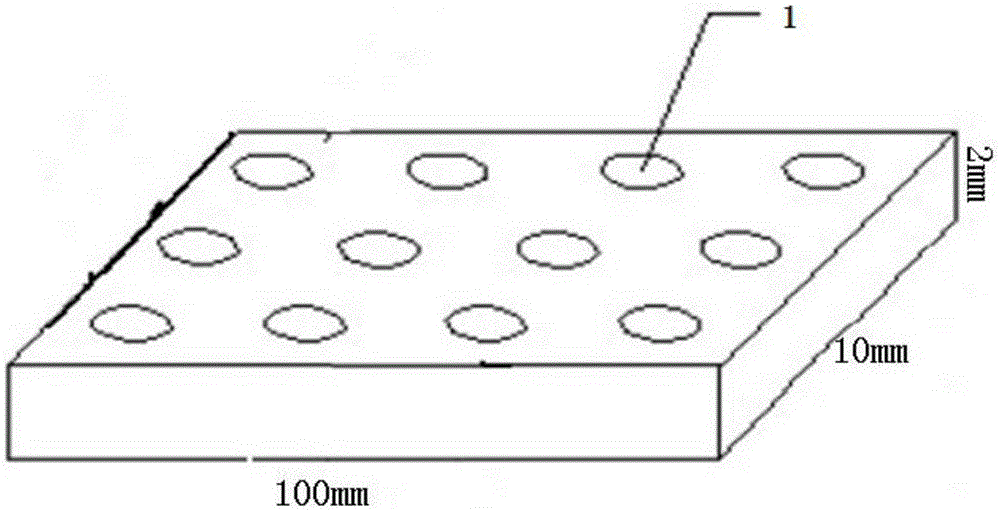

Image

Examples

Embodiment 1

[0032] The following raw materials are calculated in parts by weight: 25 parts of fir bark, 25 parts of red eucalyptus bark, 25 parts of corn straw, 25 parts of wheat straw and 5 parts of agar.

[0033] The preparation method of the nesting material comprises the following steps:

[0034] (1) Weighing fir bark, red eucalyptus bark, corn stalk and wheat straw in parts by weight, drying, and mechanically pulverizing to 10 mesh to obtain coarse powder;

[0035] (2) The coarse powder obtained in step (1) and water are added into a refiner according to a mass ratio of 5:1 for wet grinding to obtain a slurry with a particle size of 100 objects;

[0036] (3) filtering the slurry obtained in step (2), removing the filter residue, and collecting the filtrate, which is the slurry;

[0037] (4) Add agar to the slurry, stir evenly while adding the agar, then add the mold to solidify and form;

[0038] (5) drying the solidified nesting material to obtain Hu Feng's nesting material.

[0...

Embodiment 2

[0041] The following raw materials are calculated in parts by weight: 5 parts of fir bark, 10 parts of red eucalyptus bark, 10 parts of corn straw, 25 parts of wheat straw and 3 parts of pregelatinized starch.

[0042] The preparation method of the nesting material comprises the following steps:

[0043] (1) Weighing fir bark, red eucalyptus bark, corn stalk and wheat straw in parts by weight, drying, and mechanically pulverizing to 60 mesh to obtain coarse powder;

[0044] (2) The coarse powder obtained in step (1) and water are added into a refiner according to a mass ratio of 10:1 for wet grinding to obtain a slurry with a particle size of 250 objects;

[0045] (3) filtering the slurry obtained in step (2), removing the filter residue, and collecting the filtrate, which is the slurry;

[0046] (4) Add pregelatinized starch to the slurry, stir evenly while adding the pregelatinized starch, and then add the mold to solidify and form;

[0047] (5) drying the solidified nesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com